Pi control, Pid control, Dead band – Watlow Series F4P User Manual

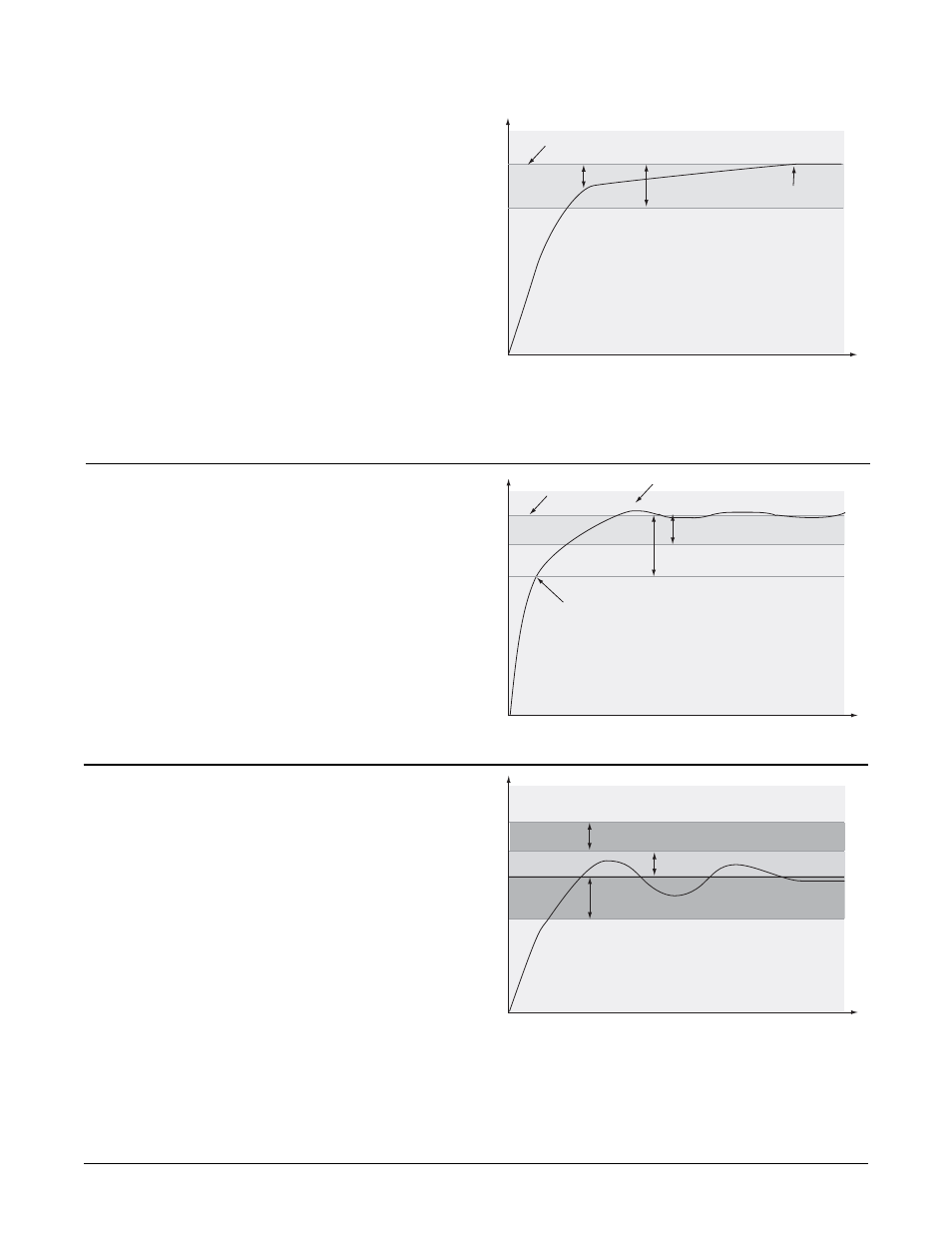

Page 65: Proportional integral derivative (pid) control, Proportional plus integral (pi) control, Figure 7.7b — pid control, Figure 7.7c — cooling dead band, Figure 7.7a — proportional plus integral control

Wa t l o w S e r i e s F 4 P

F e a t u r e s

■

7 . 7

Proportional Integral Derivative (PID)

Control

Use derivative control to minimize overshoot in a PI-con-

trolled system. Derivative adjusts the output based on

the rate of change in the temperature or process value.

Too much derivative will make the system sluggish.

Location in software: Operations Page > Edit PID > PID

Set x (1 to 5).

Figure 7.7b — PID Control.

Time

Te

mperature

Set Point

Reduced Overshoot

Proportional Band

Proportional Band x 2

Heating slows

Dead Band

In a PID application the dead bands above and below the

set point can save an application's energy and wear by

maintaining process temperature within acceptable

ranges. Shifting the effective cooling set point and heat-

ing set point keeps the two systems from fighting each

other.

Proportional action ceases when the process value is

within the dead band. Integral action continues to bring

the process temperature to the set point. When the dead

band value is zero, the heating element activates when

the temperature drops below the set point, and the cool-

ing element switches on when the temperature exceeds

the set point.

Location in software: Operations Page > Edit PID > PID

Set x (1 to 5).

Figure 7.7c — Cooling Dead Band.

Time

Te

mperature

Heating Set Point

Heating Proportional Band

Cooling Dead Band

Cooling Set Point

Cooling Proportional Band

Proportional plus Integral (PI) Control

The droop caused by proportional control can be correct-

ed by adding integral control. When the system settles

down the integral value is tuned to bring the tempera-

ture or process value closer to the set point. Integral de-

termines the speed of the correction, but this may in-

crease the overshoot at startup or when the set point is

changed. Too much integral action will make the system

unstable. Integral is cleared when the process value is

outside of the proportional band.

Integral (if units are set to SI) is measured in minutes

per repeat. A low integral value causes a fast integrating

action.

Reset (if units are set to U.S.) is measured in repeats per

minute. A high reset value causes a fast integrating ac-

tion.

Location in software: Operations Page > Edit PID > PID

Set x (1 to 5).

Figure 7.7a — Proportional Plus Integral Control.

Time

Te

mperature

Set Point

Proportional Band

Droop corrected

Droop