Inputs, Multiple input offsets – Watlow Series F4P User Manual

Page 60

Inputs

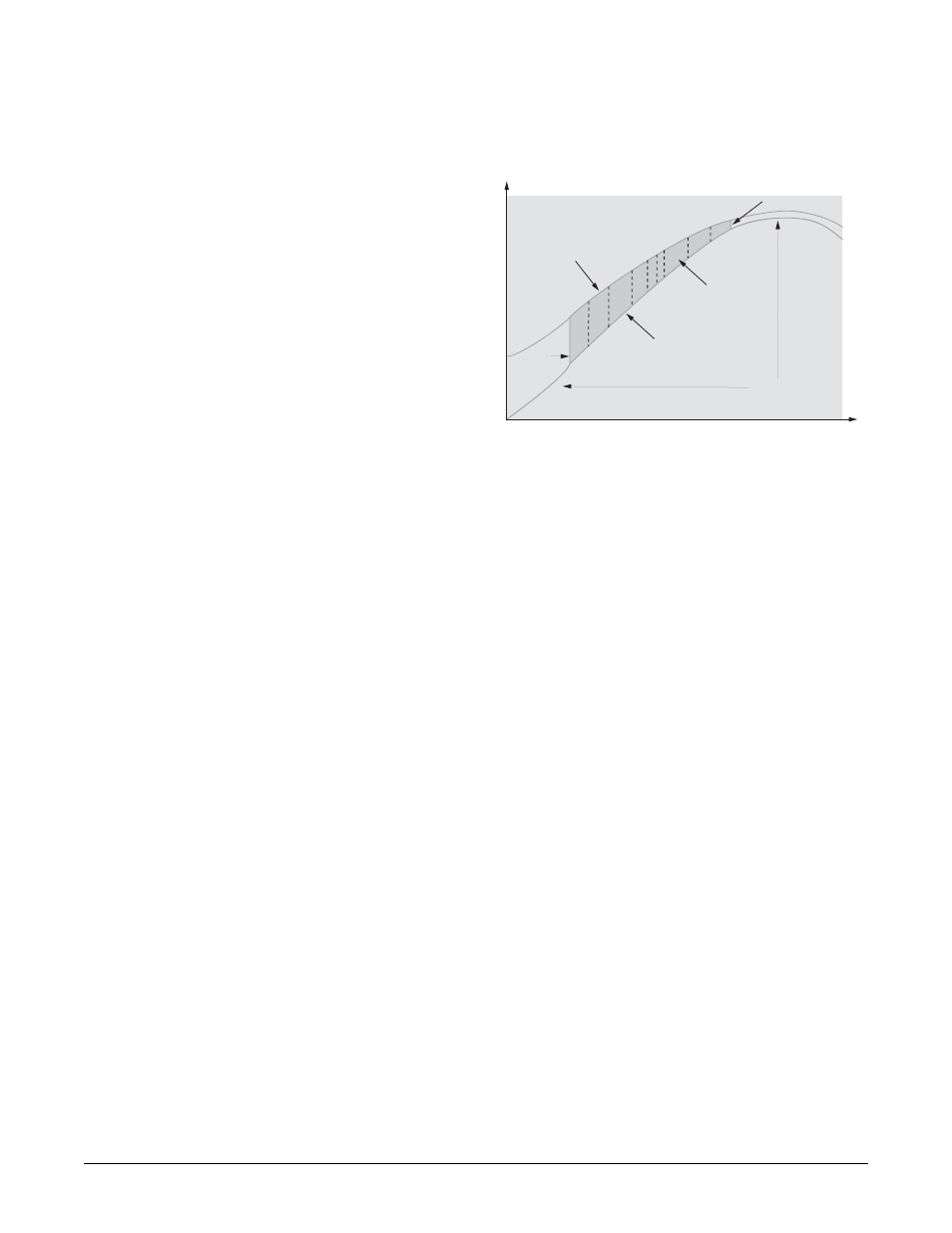

Multiple Input Offsets

Offset point are used to compensate for differences be-

tween the target process value and the sensor value read

by the Series F4P. Multiple offset points enable the F4P

to compensate for non-linear differences between the sen-

sor readings and target process values over the thermal

or process system operating range. Sensor reading differ-

ences can be caused by sensor placement, tolerances, an

inaccurate sensor or lead resistance.

The Series F4P controller supports both single point and

multiple point offsets. The choice for single or multiple

offsets is made in the Setup Page > Analog Input Menu.

A single point offset allows the F4P to control the process

to one offset value difference linearly either above or be-

low the sensed value over the entire operating range.

Multiple point offsets allow the Series F4P to control the

process to 10 different offset points over the operating

range. Each offset point has a programmable positive or

negative offset value. Offset points can be positioned any-

where over the operating range. Offset point values are

programmable between -1,000 and +1,000. Offset values

are linearly interpolated between the nearest two offset

points. Offset values are added to the sensed value to es-

tablish a target process value. Offset Point 1 is pro-

grammable as the first point or low end point of the

range. Offset points 2 through 10 follow sequentially. Off-

set values lower than the first point (point 1) or higher

than the last point (point 10) are zero.

Location in software: Setup Page > Analog Input x (1 to

3) Menu > Input Offset x (1 to 10).

Figure 7.2 — Multiple Input Offsets.

Time

Te

mperature

Reading from Sensor

with Offset

(Displayed Value)

Reading from Sensor

without Offset

(Actual Value)

Offset 10

Value

Offset 1

Value

No Offset

Offset 2

3

4

5

6 7

8

9

Offset Zone

7 . 2

■

F e a t u r e s

Wa t l o w S e r i e s F 4 P