IAI America PCON-PO User Manual

Page 91

79

6. T

roubleshooting

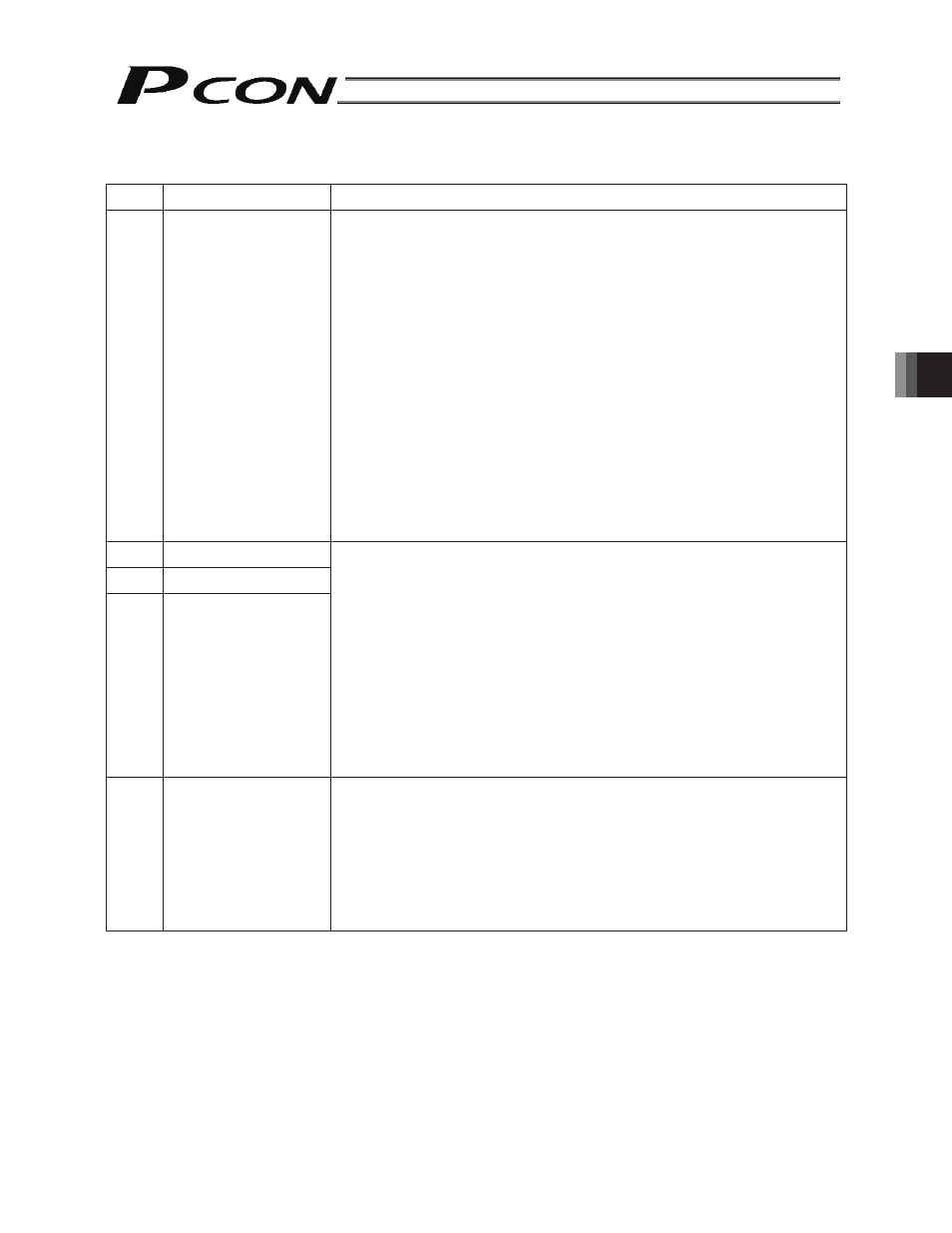

(2) Cold Start Alarms

Code

Error Cause/action

0B8

Excitation detection error This controller detects the excited phase when the servo is turned on for the first

time after turning on the power. This alarm indicates that the specified encoder

signal level cannot be detected after 100 ms of excitation.

Cause:

[1] The connector of the motor relay cable is loose or its circuit is open.

[2] If the actuator is equipped with a brake, the brake cannot be

released.

[3] The load increased due to application of external force.

[4] The power was turned on when the actuator was contacting a

mechanical end.

[5] The sliding resistance of the actuator itself is high.

Action:

[1] Check the wiring condition of the motor relay cable.

[2] Check the wiring condition of the brake cable, and also turn on/off

the brake release switch to check if “click” sound is heard.

[3] Check the assembly condition of mechanical parts for any

abnormality.

[4] Move the actuator away from the mechanical end, and then turn on

the power again.

[5] If the load is normal, cut off the power and move the actuator by

hand to check the slide resistance.

If the actuator itself is suspected as the cause, contact IAI.

0E8

Open phase A/B detected

0E9

Open phase A detected

0EA

Open phase B detected

Encoder signals cannot be detected correctly.

Cause:

[1] The connector of the encoder relay cable is loose or its circuit is

open.

[2] The connector of the supplied actuator cable is loose or its circuit is

open.

Action:

Check the connection condition of the encoder relay cable and perform

continuity check. If no abnormality is found, contact IAI.

If [3] is suspected, connect the encoder relay cable connector first, and

then connect the battery connector.

If [4] is suspected, check the model name of each encoder relay cable

and connect the correct relay cable to each actuator.

Model name of cable for high-thrust rod type:

CB-RFA-PA***

Model name of cable for other actuator types: CB-RCP2-PA***

0F4

Inconsistent PCB

This controller uses a different motor drive circuit depending on the motor

capacity, and therefore the installed printed circuit board (PCB) is also different

with each controller.

During the initialization after starting, the controller checks if the motor type set by

the manufacturer’s parameter matches the actual PCB installed.

This alarm indicates that the two do not match.

Cause:

The parameter may not be entered correctly or the PCB may not be

assembled correctly.

Action:

If you have encountered this error, contact IAI.