S/hart, profibus pa, o, Setting with one inductive proximity switch, Setting with two inductive proximity switches – Burkert Type 8635 User Manual

Page 51

8635 - 49

I

NDUCTIVE PROXIMITY SWITCHES

(S/HART, PROFIBUS PA, O

PTION

)

Settings

Definition of the end positions with part-turn actuators

Setting with one inductive proximity switch

The upper end position is to be set (Position 1 with part-turn actuators)

Move the actuator in the manual mode to the position in which initiation is to take place. Turn adjusting

wheel SR1 to the right until the current jumps from

≥ 2.1 mA to ≤ 1.2 mA.

The lower end position is to be set (Position 2 with part-turn actuators)

Move the actuator in the manual mode to the position in which initiation is to take place. Turn adjusting

wheel SR1 to the left until the current jumps from

≥ 2.1 mA to ≤ 1.2 mA.

Setting with two inductive proximity switches

The upper end position is to be set (Position 1 with part-turn actuators)

Move the actuator in the manual mode to the position in which initiation is to take place. Turn adjusting

wheel SR2 to the right until the current jumps from

≥ 2.1 mA to ≤ 1.2 mA.

On turning the adjusting wheel, take care that the other adjusting wheel is not turned.

The lower end position is to be set (Position 2 with part-turn actuators)

Move the actuator in the manual mode to the position in which initiation is to take place. Turn adjusting

wheel SR2 to the left until the current jumps from

≥ 2.1 mA to ≤ 1.2 mA.

On turning the adjusting wheel, take care that the other adjusting wheel is not turned.

First put the device into operation, as described in the chapter

Operation and Control

Functions. The function AUTOTUNE must have been executed, so that the actuator stroke

is displayed correctly.

NOTE

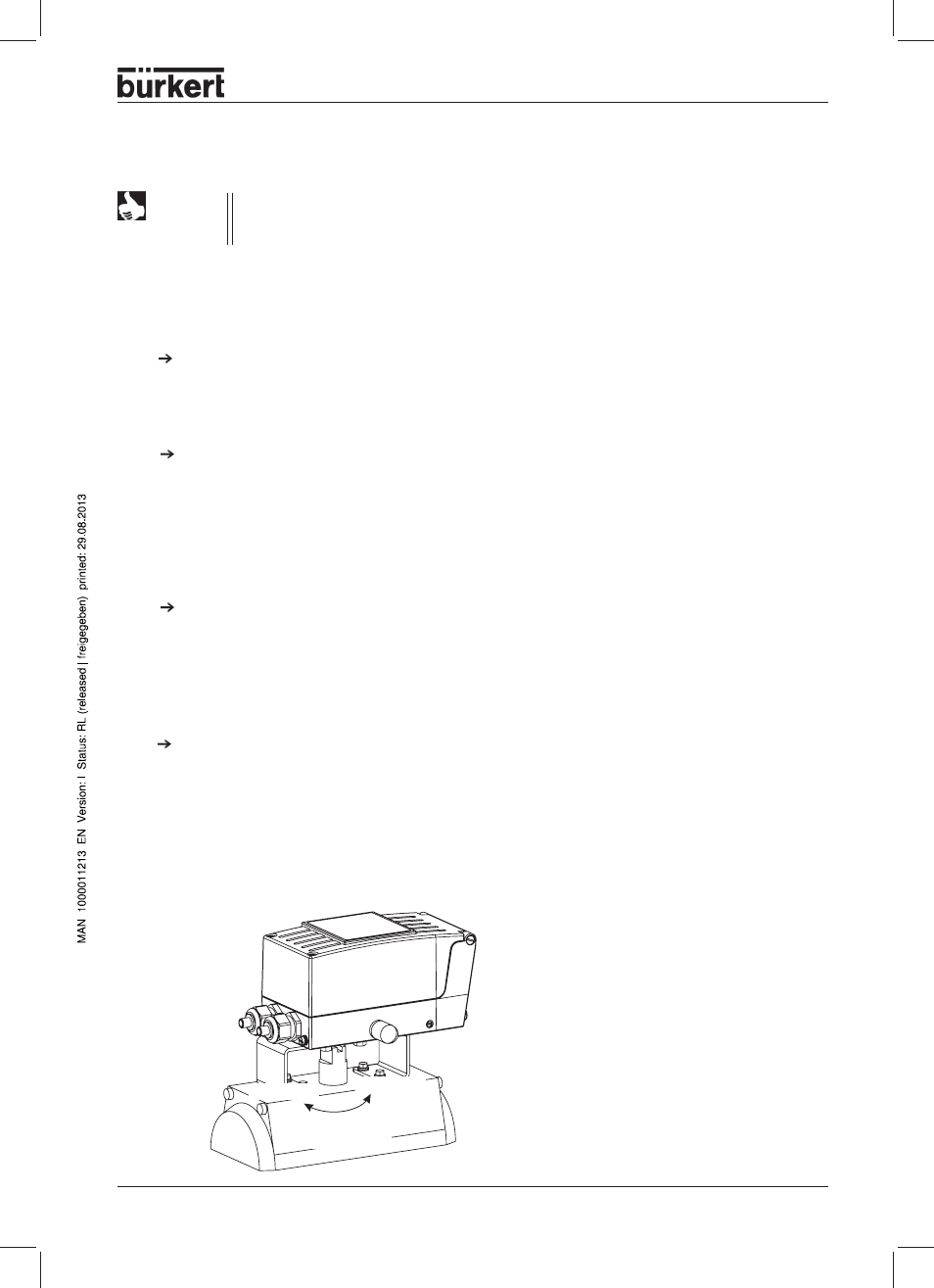

SIDE Control

Position 1

Position 2

Part-turn actuator