0 maintenance – Alpha Technologies XM3-HP Series - Technical Manual User Manual

Page 99

99

017-882-B0-001 Rev. C2 (10/2013)

4.0

Maintenance

4.4

Battery Maintenance, continued

4.4.4 Capacity

4.0

Maintenance, continued

The actual capacity is related to the utilization ratio of the active positive and negative materials

within the battery. The utilization ratio is influenced by the depth of discharge, the structure of the

battery, and the manufacturing technology. During normal usage, the factors that influence the

actual capacity are discharge rate, depth of discharge, end voltage, and temperature.

• The higher the discharge rate, the lower the available capacity.

• As batteries get colder, the available capacity is reduced (See Fig. 4-3). This is related to

the kinetics of the electrochemical reactions and the resistivity of the electrolyte.

Although the battery can be operated at temperatures below -4ºF (-20ºC), the capacity and ability

to discharge will be dramatically decreased. Similarly, temperatures approaching 122ºF (50ºC) will

increase electrolyte loss and corrosion of the plates, resulting in a shorter battery life.

NOTE:

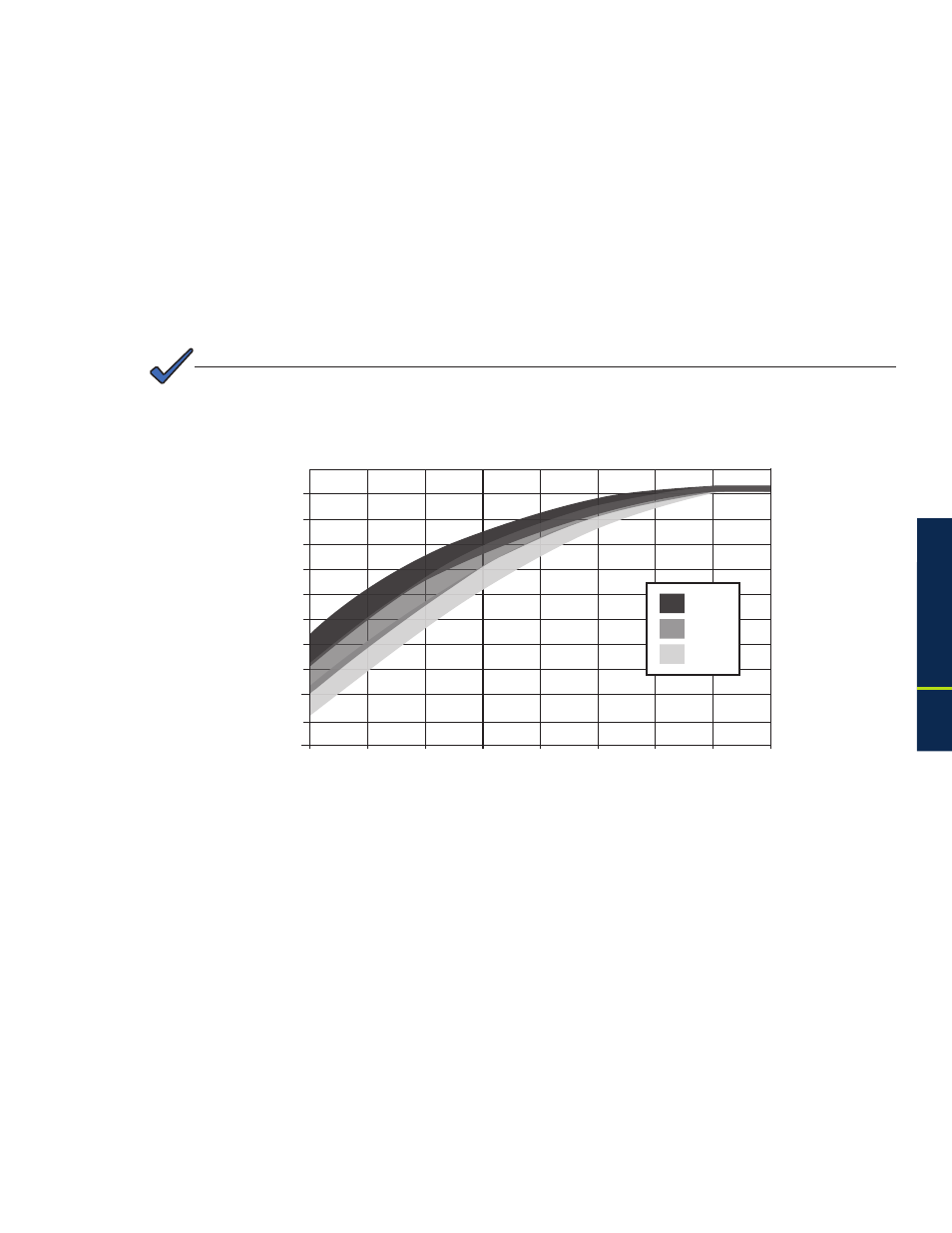

Fig. 4-4, Available Capacity vs. Ambient Temperature

-40°F/

-40°C

-22°F/

-30°C

-4°F/

-20°C

14°F/

-10°C

32F/

0°C

50°F/

10°C

68°F/

20°C

86°F/

30°C

104°F/

40°C

20%

30%

50%

70%

90%

10%

80%

60%

100%

40%

0%

Percent Rated Capacity Available

Efficiency VS. Temperature

AlphaCell 3.5HP and 4.0HP

4.0HP

3.5HP

Typical Gel

4.4.5 Preparing for Maintenance

The battery system should be remotely monitored and physically inspected periodically. If the

battery system has an automatic monitoring system to gather the electrical and environmental

data, the remote checks should consist of evaluating the recorded data and visiting any site that

does not meet the specifications listed in the detailed procedures below.

You do not have to measure the electrolyte specific gravity or add water to the cells.

All batteries in the string should be numbered to facilitate recording and analysis of data unique

to each unit.

Notify anyone affected by the intended maintenance or troubleshooting activity. This should

include but not be limited to anyone responsible for the status monitoring equipment at the head-

end or NOC.