Toshiba, Parameter tree (cont'd) – Toshiba Adjustable Speed Drive H3 User Manual

Page 69

T

OSHIBA

8 - 34

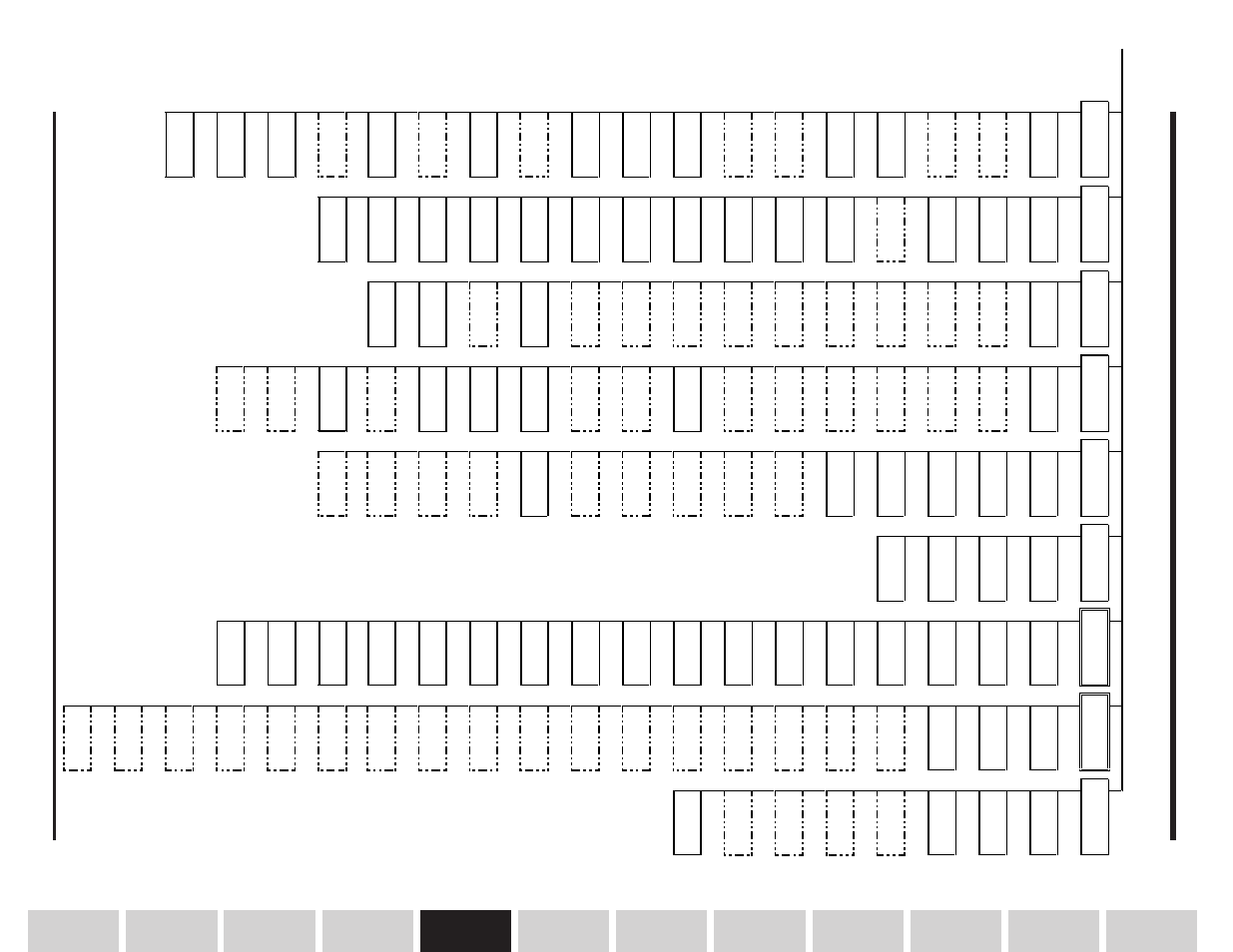

Parameter Tree (cont'd)

Pr

ot

ect

io

n Pa

ramet

er

s

P

ro

tect

ion Par

am

ete

rs

(Con

tinued

)

P

att

er

n

R

un C

ontr

ol

P

ara

m

ete

rs

F

eedb

ack Para

m

ete

rs

Com

m

uni

cat

io

n S

ett

in

g

Pa

ramet

er

s

A

M

/F

M

Ter

m

inal

Adj

ustment

Par

am

ete

rs

U

tility

P

ara

m

ete

rs

U

tility

P

ara

m

ete

rs

(Con

tin

ued

)

M

oto

r P

ara

m

ete

rs

14

2

160

17

5

243

260

275

27

9

296

31

6

Dyna

m

ic B

raki

ng

S

ele

ctio

n

M

otor 1

50% O

ver

load

Time

L

imi

t

Pat

te

rn

Run Sel

ec

tio

n

Fee

dba

ck

Cont

ro

l

S

ele

ction

RS232

Ba

ud Rat

e

FM

Ter

m

inal

Fu

nct

io

n

S

elec

tion

In

du

stria

l A

pp

lic

atio

ns

C

urr

en

t U

nits

S

elec

tion

N

um

be

r of

M

oto

r P

ole

s

14

3

161

17

6

244

261

276

28

0

297

31

7

Br

anki

ng

R

es

ist

or

Val

ue

O

ve

rlo

ad

S

ele

ctio

n

P

atte

rn

R

un

C

on

tin

ue

Mo

de

Fe

edb

ack I

nput

Si

gn

al

S

ele

ction

Num

be

r o

f Dat

a Bi

ts

Fr

equ

ency M

ete

r

Adj

ust

m

ent

St

and

ar

d Set

ting M

ode

S

ele

ctio

n

V

oltag

e U

nits

S

elec

tio

n

M

oto

r R

ate

d

C

apa

city

14

4

162

177

-18

4

245

262

277

28

1

298

31

8

Bra

king Resi

st

or

Power

R

ati

ng

St

al

l Pr

ot

ect

io

n E

nabl

e

P

at

tern

G

roup

#

1

Sp

eeds #

0 - #7

P

rop

ortio

na

l G

ain

P

ari

ty S

ettin

g

A

M

T

erm

in

al F

unct

io

n

S

ele

ctio

n

Com

m

and M

ode

S

ele

ctio

n

Bl

ind Fu

nct

ion

S

elec

tio

n

Mo

to

r T

yp

e

14

5

163

18

5

246

263

278

28

2

299

31

9

Over

vo

ltage

St

al

l

P

rote

ctio

n

S

ta

ll P

rot

ec

tio

n

C

urr

ent

Le

vel

Pat

tern

G

roup

#

1

N

umber

of

C

ycl

es

Int

eg

ra

l G

ain

Inv

ert

er

ID

N

um

be

r

C

urr

en

t M

ete

r

Adj

ust

m

ent

Fr

eq

uen

cy

M

ode

S

ele

ction

Fu

nda

m

ent

al

P

ara

m

ete

rs

#

2 B

lin

d

M

oto

r R

ate

d V

oltag

e

14

6

164

186

-19

3

247

264

28

3

300

32

0

D

C

In

je

ctio

n S

tar

t

Fr

eque

ncy

Unde

rvol

ta

ge Tr

ip

S

ele

ctio

n

Pat

tern

G

roup

#

2

Sp

eeds #

0 - #7

A

nti H

untin

g G

ain

C

om

m

un

ica

tio

n

S

ele

ctio

n

P

anel

Oper

at

io

n M

ode

S

ele

ctio

n

Pane

l Con

trol

P

ara

m

ete

rs

B

lin

d

Mo

to

r R

ate

d

Fr

equ

ency

14

7

165

19

4

248

265

28

4

301

32

1

D

C

In

je

ctio

n C

urre

nt

M

ag

nitu

te

Unde

rvo

ltage Det

ect

Ti

m

e

Pat

tern

G

roup

#

3

N

umber

of

C

ycl

es

Lag Ti

me C

onst

ant

M

as

te

r/S

lave

Se

lect

io

n

P

ass

Num

ber

Ter

m

in

al S

elect

io

n

P

ara

m

ete

rs

B

lin

d

M

oto

r R

ated

R

P

M

14

8

166

195

-20

2

249

266

28

5

302

32

2

D

C

In

jec

tion

T

im

e

Lo

w

C

urre

nt D

ete

ct

S

ele

ctio

n

Pat

tern

G

roup

#

3

Sp

eeds #

0 - #7

PI

D

L

ow

er Fr

equ

ency

Lim

it

RS485

Ba

ud Rat

e

C

P

U V

ersi

on

S

peci

al

Cont

ro

l

P

ara

m

s B

lin

d

Aut

o-T

un

ing Ena

ble

14

9

167

20

3

250

267

28

6

303

32

3

Fw

d/

R

ev

D

C

In

j.

P

rior

ity

c

on

tro

l

Low C

urr

ent

Det

ect

Le

vel

Pat

tern

G

roup

#

3

N

umber

of

C

ycl

es

P

ID D

evi

at

ion L

im

it

S

ele

ction

TOS

LIN

E F10

/S2

0

C

omma

nd

In

pu

t

RO

M

Ver

sio

n

Fre

que

ncy S

ett

ing

P

ara

m

s B

lin

d

Load M

om

ent

of

In

ert

ia

15

0

168

204

-21

1

251

268

28

7

304

Mot

or Sh

af

t st

ati

onar

y

cont

ro

l

Low C

urr

en

t Det

ect

io

n

Ti

m

e

Pat

tern

G

roup

#

4

Sp

eeds #

0 - #7

PI

D

Devi

at

io

n U

pper

Lim

it

TOS

LIN

E F10

/S2

0

M

on

ito

r O

utp

ut

E

E

P

R

O

M

V

ers

io

n

P

ro

te

ction

F

un

ction

P

ara

m

s B

lin

d

15

1

169

21

2

252

269

28

8

305

Em

er

ge

ncy O

ff M

ode

S

ele

ction

Out

put

Shor

t C

ircui

t

Det

ect

io

n Sel

ect

Pat

tern

G

roup

#

4

N

umber

of

C

ycl

es

PI

D

Devi

at

io

n Lower

lim

it

TOS

LIN

E F10

/S2

0

C

om

m

E

rro

r M

od

e

Inve

rter

TypeFo

rm

P

at

te

rn

R

un Cont

ro

l

P

ara

m

s B

lin

d

15

2

170

21

3

253

270

28

9

306

Em

er

gen

cy

Of

f DC

In

ject

ion Ti

m

e

O

ver

to

rq

ue

T

rip

S

ele

ctio

n

Sp

eed #

1 C

ont

inue

M

ode

PG In

put

Num

be

r of

P

ulses

RS

485/

12

-Bi

t Bi

nar

y

B

ias

, G

ain

S

ta

tu

s M

oni

to

r #1

Di

spl

ay

S

elect

Fe

edb

ack C

ont

ro

l

P

ara

m

s B

lin

d

15

3

171

21

4

254

271

29

0

307

Num

be

r of

Ret

ry

A

tte

m

pts

Over

torq

ue Tr

ip

Le

vel

Sp

eed #

1 D

rive Ti

m

e

PG In

put

Num

be

r of

Pha

ses

RS

485/

12

-Bi

t Bi

nar

y

po

int

#1

S

ta

tu

s M

oni

to

r #2

displ

ay Sel

ect

C

om

m

uni

ca

tion

P

ara

m

s B

lin

d

15

4

172

215

-24

2

255

272

29

1

308

Tim

e B

etw

ee

n R

etry

A

tte

m

pts

Fau

lt T

rip

EEPRO

M

Save

E

nabl

e

Speed

s 2 - 15

Dr

ive

Ti

m

e

Dr

oopi

ng Cont

ro

l

Enab

le

RS

485/

12

-Bi

t Bi

nar

y

pt

. #1 Fr

eq

S

ta

tu

s M

oni

to

r #3

Di

spl

ay

S

elect

Indust

rial

App

l: Pum

p

P

ara

m

s B

lin

d

15

5

173

215

- 24

2

256

273

29

2

309

Regen

er

at

ion Power

Ri

de Th

rou

gh

C

ool

in

g Fan Cont

ro

l

S

ele

ctio

n

Spee

ds 2-

15 Cont

in

ue

m

ode

Dr

oopi

ng Cont

ro

l

A

m

ount

RS

485/

12

-Bi

t Bi

nar

y

po

int

#2

S

ta

tu

s M

oni

to

r #4

Di

spl

ay

S

elect

In

dust

rial

Appl

: Fan

P

ara

m

s B

lin

d

156

17

4

257

27

4

29

3

31

0

Regen

er

at

io

n Ri

de

Th

ro

ug

h tim

e

Cum

ula

tive R

un Ti

m

er

A

la

rm

S

ettin

g

O

ver

ride Cont

ro

l

S

ele

ctio

n

RS48

5/

12-

Bi

t B

in

ary

pt.

#2

F

re

q

Fr

eq

uen

cy

Uni

ts

Scal

e

Fact

or

Ind

us

tria

l A

pp

l:

Con

veyor

B

lin

d

157

25

8

29

4

31

1

Aut

o-r

est

ar

t (

m

ot

or

spe

ed sea

rch)

O

ve

rride

M

ultiplie

r

Input

Sel

ecti

on

Fr

eq

uency Di

spl

ay

Resol

uti

on

In

du

stria

l A

pp

l: H

ois

t

B

lind

158

25

9

29

5

31

2

E

le

ctron

ic Ther

m

al

Prot

ec

t L

evel

1

O

ver

rid

e Chang

e

M

ultip

lie

r

AC

C/

DE

C Ti

m

e Uni

ts

S

ele

ctio

n

Ind

us

tria

l A

pp

l:

Te

xtile

s B

lin

d

159

31

3

Over

load

Red

uct

ion

S

ta

rt Fr

eq.

In

dust

rial

Appl

: Too

ls

B

lind

31

4

AM

/F

M

Adj

us

tm

ent

P

ara

m

s B

lin

d

31

5

M

oto

r Pa

ramet

er

s

B

lind

Specifications

Precautions

Wiring

Jumpers

Panel

Keypad

Parameters

Programming

Service

Dimensions

Index

Inspection