Water level switch, Water level switch operation, Important – Maytag Atlantis User Manual

Page 86: Testing the water level switch, Water level switch -14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

WATER LEVEL SWITCH

Water Level Switch Operation

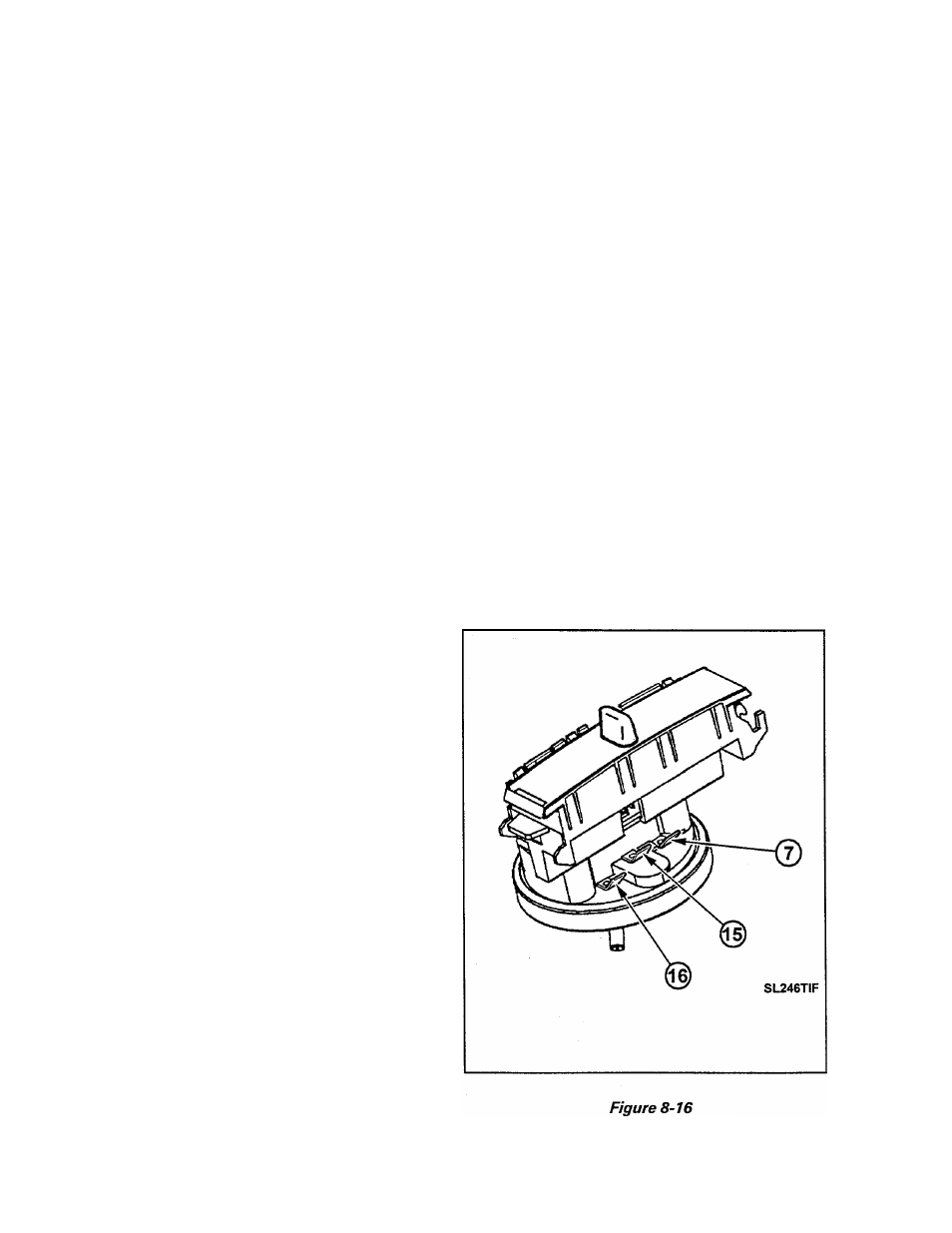

The water level switch is secured to the con

trol console by means of two locking tabs on

the switch body [Figure 8-16).

The water level switch is operated by a col

umn of air that becomes trapped in the pres

sure switch hose. This hose is connected be

tween the diaphragm section of the switch

and air bell which is located on the lower por

tion of the tub. As water enters the tub, a

small amount enters the pressure switch hose

thereby trapping air in the hose. As the water

level increases in the tub, this column of air

becomes compressed and exerts pressure on

the water level switch diaphragm. When the

proper water level is reached the diaphragm

actuates a single pole, double throw switch in

the water level switch assembly.

The water level switch is quite sensitive and

requires only about 0.6 RS.I. to activate it at

the maximum fill position.

It is most important that the hose connections

to the switch diaphragm and air bell nipple

be airtight, as the smallest air leak will cause

erratic operation.

__ IMPORTANT_____________________

The water level switch is adjusted and

sealed at the manufacturing source and no

adjustments should be made in the field.

Whenever the hose is removed from the wa

ter level switch or the air bell nipple, DO NOT

reconnect the hose until all water has been

drained from the tub. To ensure proper op

eration of the water level switch, the hose

MUST NOT have any water in it when rein

stalled on the switch. When reconnecting the

hose, be sure to slip it over the nipple(s) as far

as possible.

The circuitry of the machine is designed to

put the switch in control of the water mixing

valve or the timer motor and drive motor dur

ing various phases of the wash cycle.

During the fill cycle, the switch makes a cir

cuit between terminals 7 and 15 which ener

gizes the mixing valve circuit(s). (Figure 8-

16) When the switch is activated, it opens the

circuit between terminals 7 and 15 which

shuts off the water, and closes a circuit be

tween terminals 7 and 16 which energizes the

timer motor and drive motor.

Testing the Water Level Switch

The water level switch can be accessed as pre

viously detailed in Section 4 under Control

Pane! Disassembly. It can be tested using an

ohmmeter and executing the following.

16009485-01

Section 8. Electrical Components & Testing

©1999 Maytag Appliances Sales Company

8-16