Suspension housing, Tub braces, Suspension springs – Maytag Atlantis User Manual

Page 52: Suspension housing -2, Tub braces -2, Suspension springs -2

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

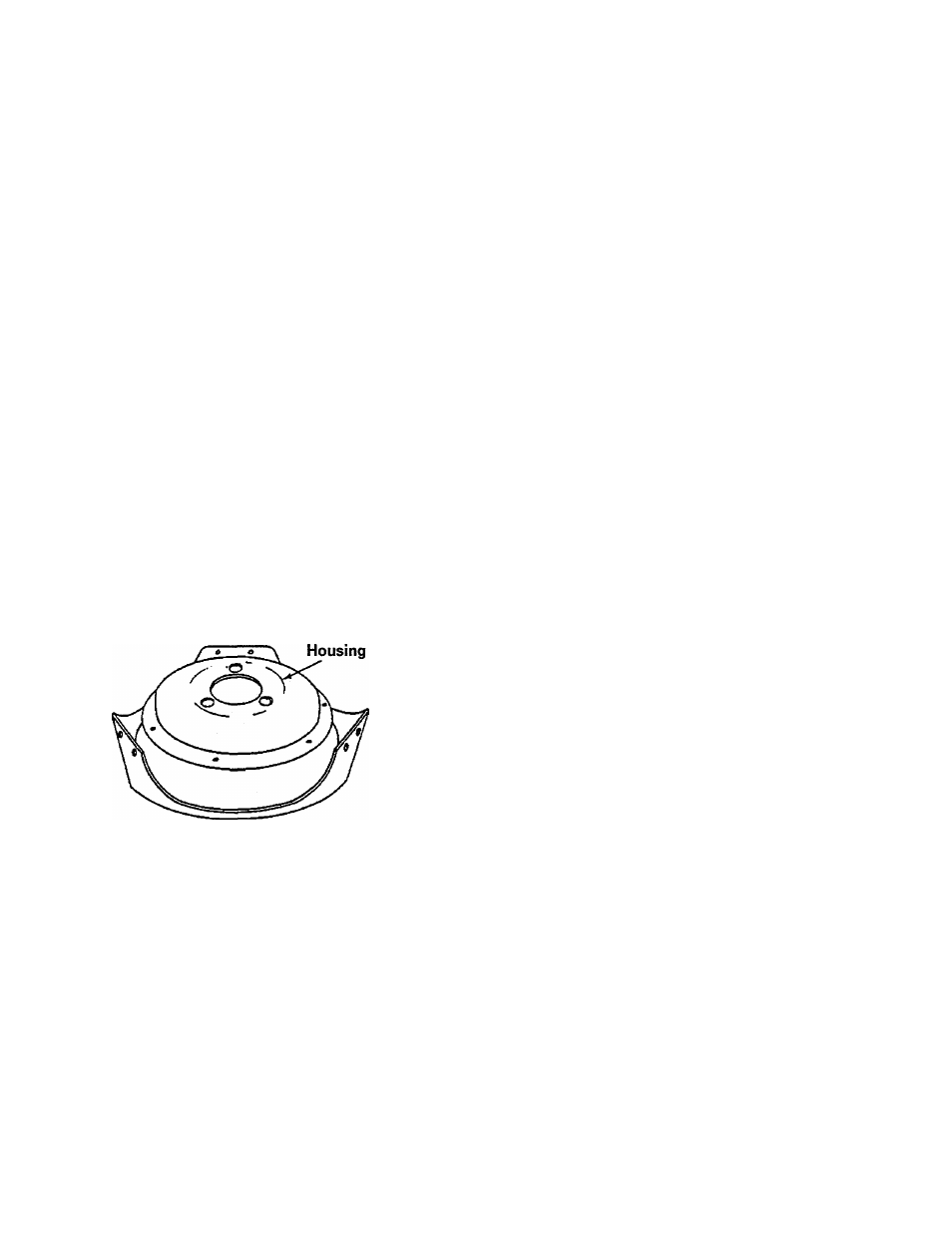

SUSPENSION HOUSING

The suspension housing is fabricated of heavy

gauge steel. It rests on the raised domelike

area in the center of the base and supports

the weight of the transmission, outer tub, and

spin basket (Figure 6-2).

The underside of the suspension housing pro

vides mounting for the snubber pad and also

houses the brake assembly (Figure 2-2).

The bottom of the housing has been formed

into a spherical configuration and, along with

the snubber, rides on the domed area of the

base which allows the housing to move freely

in all directions.

The top of the suspension housing is attached

to the lower bearing assembly with three

mounting screws. These screws thread from

the underside of the suspension housing dome

into the die-cast bearing housing.

3. Remove the brake assembly as detailed in

Section 7.

4. Remove screws securing housing to the

lower bearing assembly.

TUB BRACES

The tub braces are attached at the top to the

tub support, and to the suspension housing

at the bottom. The tub braces are located

behind iic\e tub support and suspension hous

ing where large, thread forming screws are

driven directly into the braces to secure them.

NOTE: Should a tub brace mounting screw

hole become stripped, a nut can be installed

on the thread forming screw.

The extended end of the suspension spring

fits through an extruded hole in the tub brace

just below the mounting screws.

/

Suspension

Figure 6-2

Service to the suspension housing, other than

replacing it, is limited to replacing one of the

other components that mount to the housing.

The replacement procedures for these com

ponents are detailed in the Transmission Sec

tion of this manual.

REMOVAL

1. Disconnect power to the unit.

2. Remove the transmission assembly as de

tailed in Section 7.

SUSPENSION SPRINGS

The suspension springs hold the entire wash

unit in firm contact with the base. To reduce

wear and prevent squeaks; grease has been

applied to the friction points of the springs.

REMOVAL

The suspension springs can be removed and

replaced by using the spring tool, part num

ber 22002922 as follows:

1. Disconnect power to the unit.

2. Remove the front panel and rear access

panel.

3. Pull or block the tub in the direction of the

spring to be removed.

NOTE: Removing the tub top will allow the

tub to travel further and extend the spring less.

16009485-01

©1999 Maytag Appliances Sales Company

Section

6

. Suspension System

6-2