Motor, Motor mounting, Motor -9 – Maytag Atlantis User Manual

Page 84: Motor mounting -13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Motor

If the motor runs in one direction but will not

reverse, the problem is in the timer or wiring

harness, not in the motor. The same motor

components are used when the motor runs

in either direction; the only change is in the

electrical circuitry feeding the start winding

which is controlled by the timer and related

wires.

A two conductor test cord which has two fe

male spade connector terminals on each con

ductor is needed to test the motor operations

(tool number 038183).

To test a motor, connect the two spade con

nectors on one side of the cord to terminals 1

and 4 on the starting switch and the two con

nectors on the other side of the cord to the

starting switch terminals 2 and 3.

To check the slow speed operation, change the

lead on terminal 3 to terminal 5. Be sure to

test the motor in its normal vertical position.

If the motor will not start, or if it starts but

does not attain normal speed, check the op

eration of the external motor switch, replace

the motor.

NOTE: Normal resistance of the motor wind

ings should be:

NORMAL SPEED

1.3 OHMS

SLOW SPEED

2.3 OHMS

START

3.1 OHMS

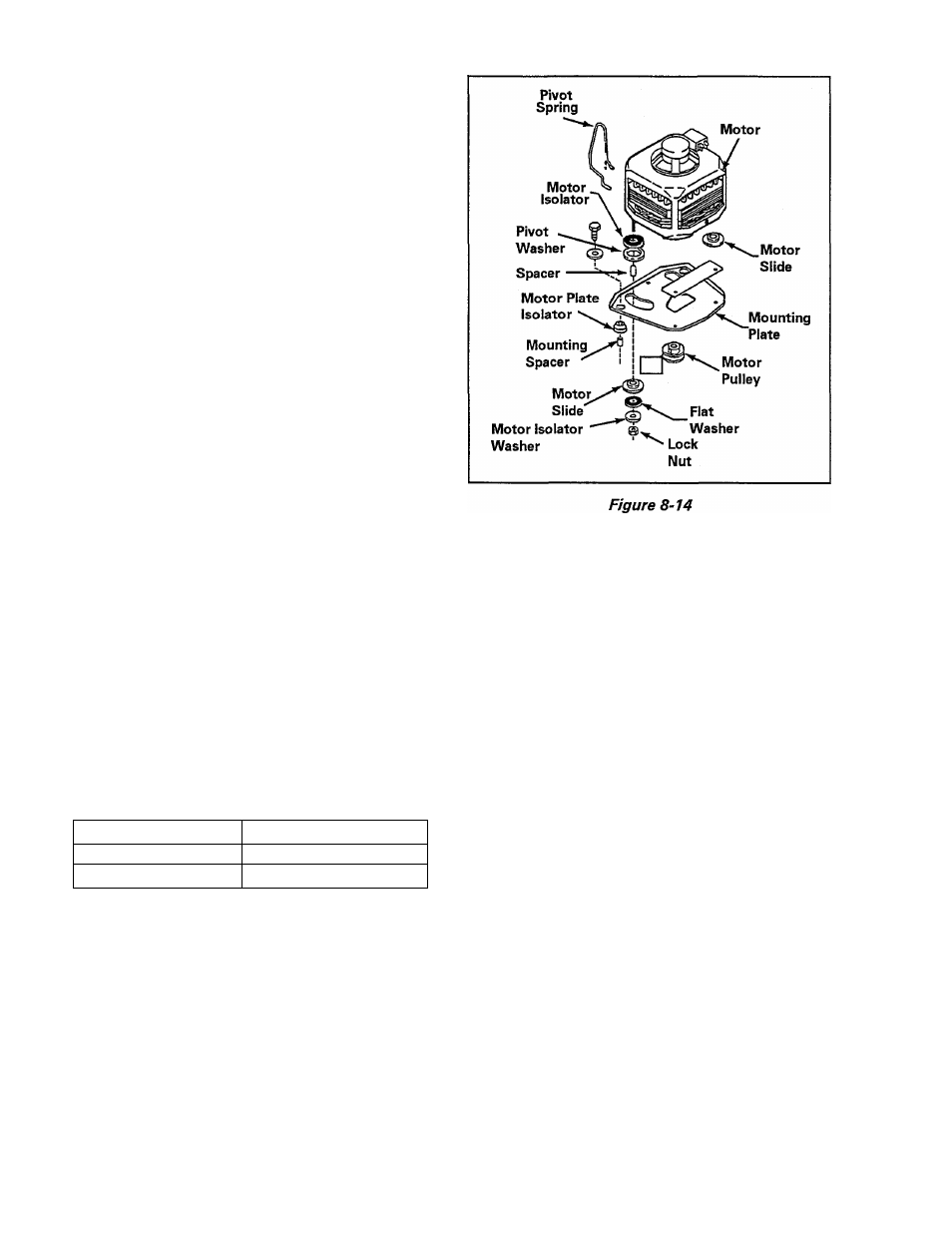

MOTOR MOUNTING

The motor mount system consists of a motor

and mounting plate assembly as shown in

(Figure 8-14).

Assembled to the motor studs and secured

by locknuts are rubber isolators and washers

which sandwich nylon washers and slides

through slots in the mounting plate. A nylon

slide is attached to the motor bottom, and a

pivot spring installs between the motor and

mounting plate.

In operation, the nylon washers and slides ride

in the slots in the mounting plate, and the slide

rides the mounting plate. The motor is free

to pivot in either direction and the pivot spring

ensures proper belt tension on the motor

pulley.

The mounting plate has rubber mounting

cushions assembled to its rear corners, and

the entire assembly is mounted to the washer

base by two (2) large hex head screws.

REMOVAL

1. Disconnect power to the unit.

2. Tip washer and remove drive belt.

3. Remove the front panel.

,y

16009485-01

Section 8. Electrical Components & Testing

©1999 Maytag Appliances Sales Company

8-14