Rf pcb assembly – part iii – Elecraft XV Assembly Manual for XV222 User Manual

Page 50

- 47 -

RF PCB Assembly – Part III

In the following steps you will install the RF power module. The procedure is

the same for all three transverter models.

If you purchased the optional feet and bail for your transverter, install

them on the bottom cover now.

You will use the following small hardware:

14 pan head black screws, 3/16” (4.8 mm) 4-40 thread.

2 pan head black screws, 1/2” (12.7 mm) 4-40 thread.

2 nuts, 4-40 thread.

4 2-D fasteners.

2 flat washers, #4.

2 inside tooth lock washers, #4.

8 split lock washers, #4.

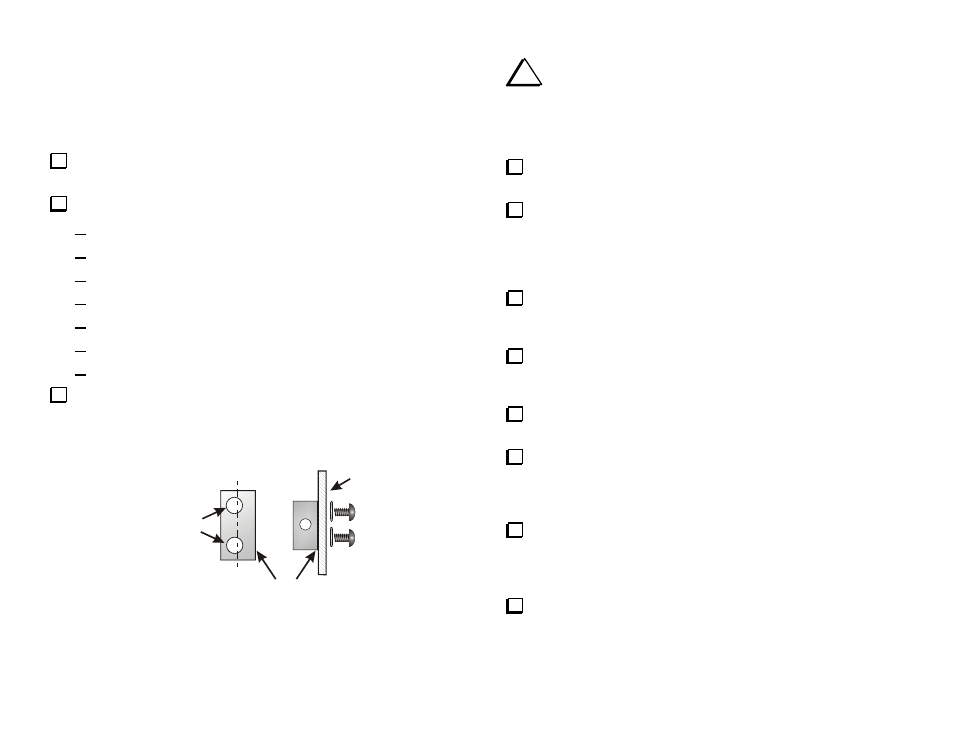

Install four 2-D fasteners on the bottom corners of the RF PCB. Line up

the offset holes of each 2-D fastener so the side of the connector is flush with

the edge of the PCB (see Figure 34). Secure each connector to the PCB with

two black 3/16” (4.8 mm) pan head screws and split lock washers.

HOLES OFFSET

FROM CENTER

TOP OF

BOARD

LINES UP FLUSH

WITH EDGE OF

BOARD

C

L

Figure 34. 2-D Fasteners.

i

In the following steps you will install the hardware that

attaches the RF power module to the bottom cover. Follow the steps

carefully to ensure the module makes good thermal contact with the

bottom cover and the leads line up properly with the RF PCB. The

completed hardware assembly is shown in Figure 38 .

Locate the bottom cover. The bottom cover has two sets of cooling

holes.

On the inside surface of the bottom cover, locate the four holes that

match the holes in the heat spreader. They are between the two sets of

cooling holes. Test-fit the larger of the two thermal conduction pads so

that the holes in the pad line up with the holes in the cover. Orient the pad

so it does not hang over the edge of the bottom cover.

Lift the thermal conduction pad and clean the surface of the bottom

cover under the pad using sandpaper, a sharp knife or other tool. The pad

must rest against clean, bare metal.

Clean the paint off of the inside surface of the bottom cover around

the screw holes in the four corners where the 2-D fasteners will attach it

to the RF PCB (See Figure 37).

Inspect the edges of the heat spreader and remove any burrs with the

edge of a flat-blade screwdriver, knife or small file.

Replace the larger of the two thermal conduction pads over the clean

metal area on the inside of the bottom cover so that the holes line in the

pad line up with the holes in the cover. Be sure the pad does not hang

over the edge of the bottom cover.

Place the heat spreader on the thermal conduction pad on so the

screw holes line up. Put a 1/2” (12.7 mm) pan head screw through each

unthreaded hole with the head on the bottom cover. Place a nut on each

screw and finger tighten.

Insert two black 3/16” (4.8 mm) pan head screws through the bottom

cover into the threaded holes in the head spreader. Tighten the screws.