Metrohm NIRS XDS Process Analyzer – DirectLight/NonContact User Manual

Page 40

38

▪▪▪▪▪▪▪

The illumination fiber bundle (or pair, if Dryer

Probe) must be attached to the proper SMA

connection port on the lamp box for correct

operation. In this instrument, white light is sent to

the sample channel only when commanded by the

software. Therefore it is essential that the channels

be hooked up correctly.

This photo shows the numbered channel positions.

(They are not numbered on the unit.) Fibers are

attached before shipment, and are tested in those

positions.

The unmarked position (with fiber attached) is the

internal reference fiber, which is routed to the

entrance slit of the monochromator.

Tightening torque is 8 in-lb (0.9Nm). Do not exceed the recommended torque.

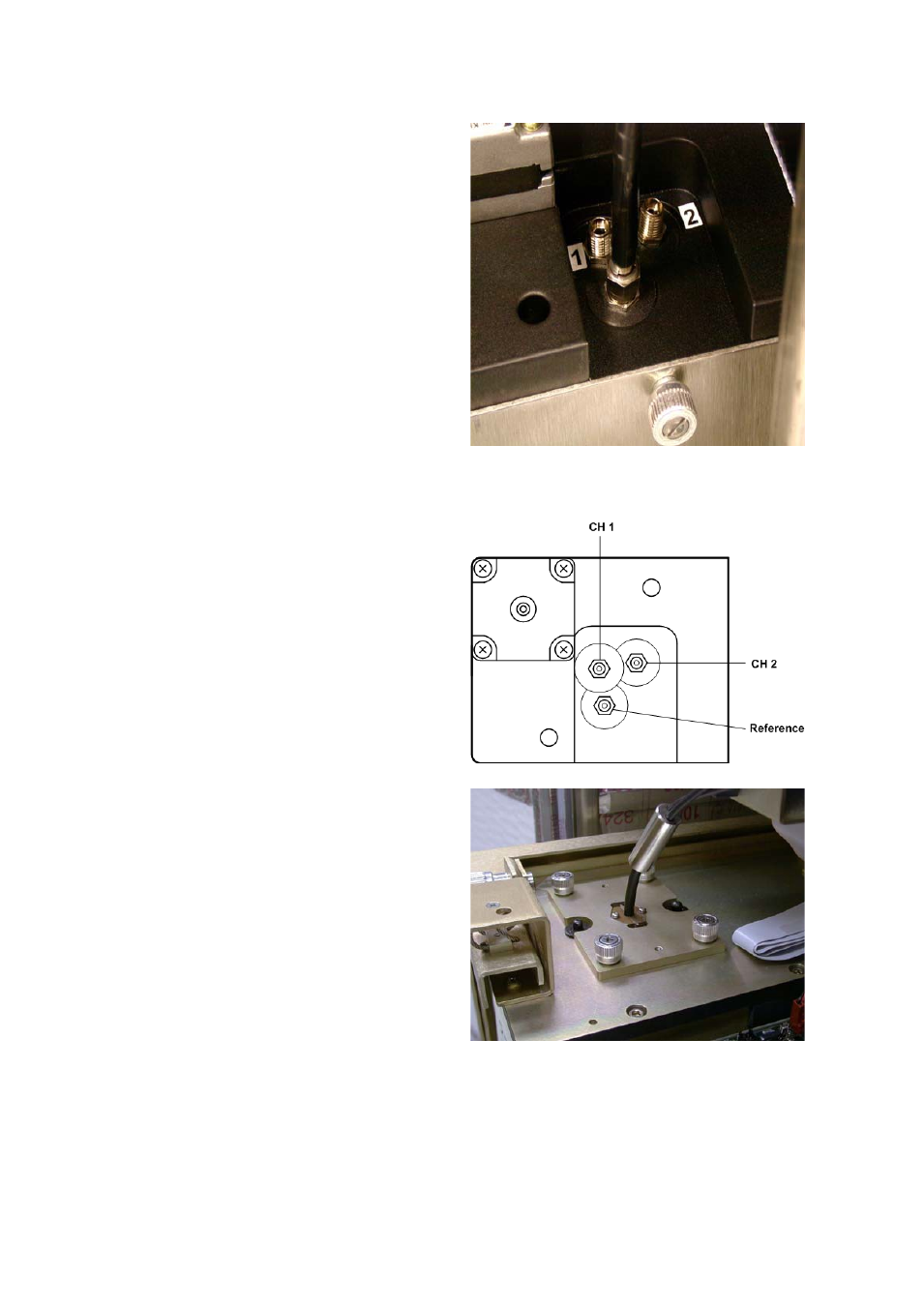

This diagram shows the layout of the lamp hookup

area. Verify that the sample channel(s) are properly

routed.

Again, fibers are attached and tested at the factory

prior to shipment. Do not remove fibers unless

absolutely necessary. Where only one sample fiber

is used, a black cap may be present over the CH2

port.

If fibers must be removed, label each one to

indicate where it should be re-attached.

A suitable wrench is the NC-100 with 5/16” (about

8mm) head, made by Seekonk Manufacturing Co.,

Seekonk, MA 02771, USA. Remove caps from

unused channels to facilitate access, then replace

caps. The head on the NC-100 is large, and may be

hard to turn if caps are not removed before use.

This photo shows where the reference fiber is

attached to the input slit of the monochromator.

Do not remove this assembly; it is shown for

familiarization purposes only.

Note that the fiber is split just beyond the cylindrical bezel. One branch is from the lamp box, and the

other is from the sample channel.Because light will be received from only one channel at a time, the

fibers are combined. The software knows which channel is receiving light at a given time.

Manual section 14.0 explains disassembly of lens barrel from the fiber bundles. In many cases the

lens barrel is mounted first, then the fiber is inserted, to minimize stress on the fiber bundle assembly.