2 purging, 2 class, group and division ratings, Purging – Metrohm NIRS XDS Process Analyzer – DirectLight/NonContact User Manual

Page 15: Class, group and division ratings

▪▪▪▪▪▪▪

13

2.1.2

Purging

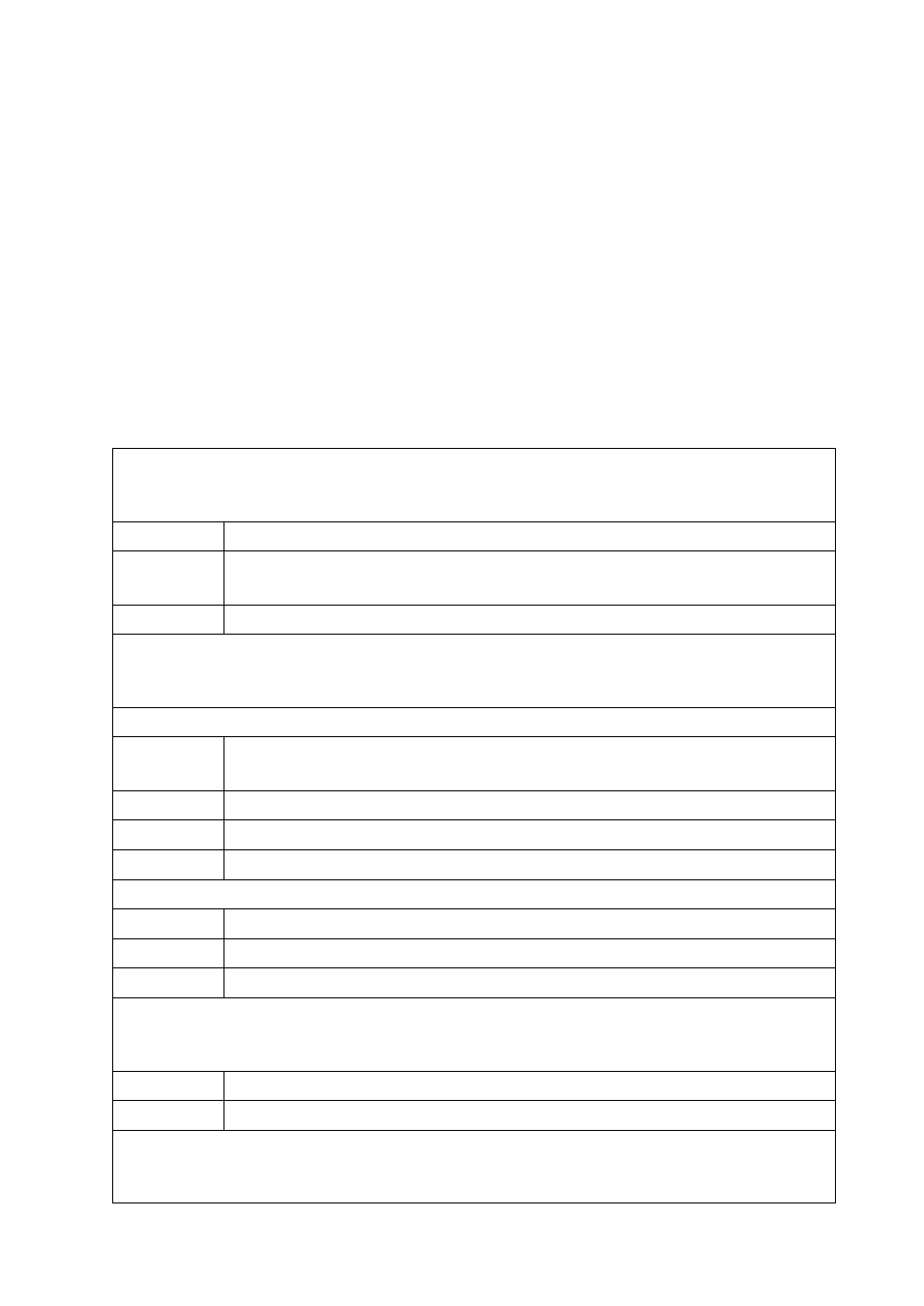

COMMON EQUIPMENT IN CLASS I AREAS

As strictly defined by NFPA 496, this method is a start-up process of Class I area pressurizing which

removes flammable vapors from a protected enclosure. This is accomplished by exchanging a known

volume of protective gas, while maintaining a minimum positive enclosure pressure of 0.10 inches of

water.

2.2

Class, Group and Division Ratings

The 1993 edition of NFPA 496 recommends 4 volume exchanges for all enclosures and 10 volume

exchanges for all motors.

NOTE: The word “purging” is commonly used as a term to define the complete process of

pressurizing protected enclosures in Class I areas.

Class Ratings

Classes are used to define the explosive or ignitable substances which are present in the

atmosphere.

Class I

Flammable gases or liquid vapors (See examples in Group Ratings)

Class II

Ignitable metal, carbon or organic dusts (See examples in Group

Ratings)

Class III

Ignitable fibrous materials

Group Ratings

Groups are used to define substances by rating their explosive or ignitable nature, in relation to

other known substances.

TYPICAL CLASS I SUBSTANCES

Group A

Acetylene (XDS Process Analytics system is not used in Group

A)

Group B

Hydrogen or > 30% Hydrogen by Volume

Group C

Ethyl Ether & Ethylene

Group D

Acetone, Ammonia, Benzene & Gasoline

TYPICAL CLASS II SUBSTANCES

Group E

Aluminum, Magnesium & Alloys

Group F

Carbon, Coke & Coal

Group G

Flour, Grain, Wood, Plastic & Chemicals

Division Ratings

Divisions are used to define the degree of hazard by determining the explosive or ignitable

substance’s expected concentration in the atmosphere.

Division 1

Contains substances under normal conditions

Division 2

Contains substances under abnormal conditions

IMPORTANT NOTES:

Division 1 areas must be surrounded by Division 2 areas. Class II, Group E areas must be rated as

Division 1 areas.