Enabling the position loop, Position reference selection – Rockwell Automation 20D PowerFlex 700S with Phase I Control Reference Manual User Manual

Page 84

84

Rockwell Automation Publication PFLEX-RM002D-EN-E - August 2013

Chapter 1

Detail Drive Configuration and Operation

Enabling the Position Loop

To enable the position loop, set parameter 151 [Logic Command] bit 13

“PositionEnbl” = 1.

Then to allow the output of the position loop to trim the speed set parameter 740

[Position Control] bit 1 “Speed Out En” = 1.

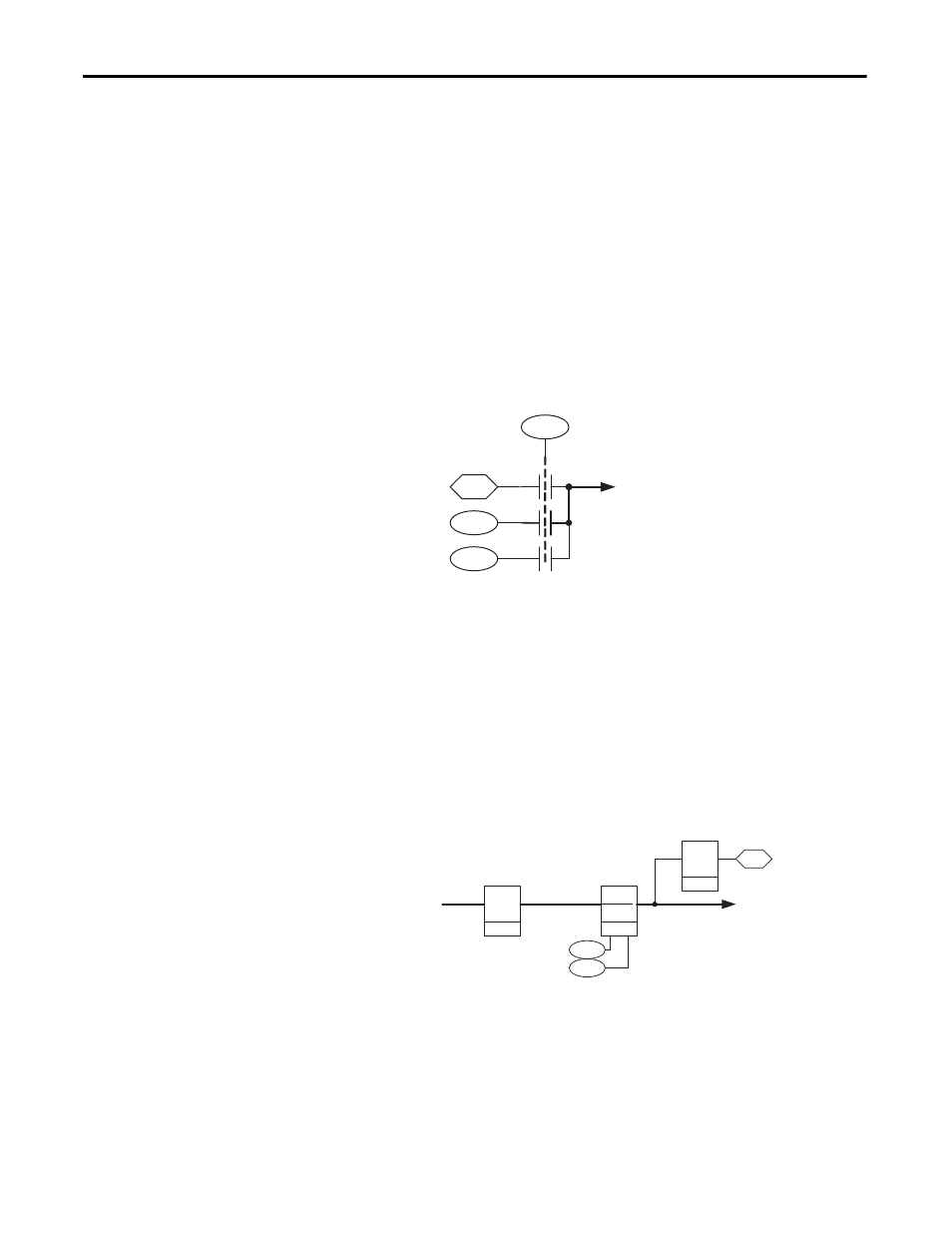

Position Reference Selection

For a position follower application set parameter 742 [Posit Ref Sel] = 1 “Aux

PositRef ”. This uses counts from a linked source for the position reference to the

position loop.

Link parameter 742 [Aux Posit Ref ] to the position for the feedback device. For

example, link parameter 742 [Aux Posit Ref ] to parameter 240 [Encdr1

Position]. Encoder 1 position becomes the position reference for the position

loop.

Set the EGR (Electronic Gear Ratio) and Speed Reference Scaling

Position reference can be entered in user units by using the EGR scaling.

Parameters 745 [PositRef EGR Mul] and 746 [PositRef EGR Div] are used to

scale the position reference.

Example:

In this example the encoders are mounted on the motors. The motors

are directly coupled to the load and we want the follower to run at 4 times the

speed of the master.

PPRm

= 1024 PPR

PPRf

= 1024 PPR

Ratiof:Ratiom

= 4:1

0

1

2

749

743

742

Interp Position

Posit Ref Sel

758

Aux PositRef

Pt-Pt Posit Ref

Selected

Position

Reference

Gear Rat

[ N ]

[ D ]

745

746

PositRef EGR Mul

PositRef EGR Div

Accum

744

PositRef EGR Out

Deriv

Δ

∑

Selected position

reference

Geared position

reference