Droop, Dynamic braking, Efficiency – Rockwell Automation 20D PowerFlex 700S with Phase I Control Reference Manual User Manual

Page 53: Electronic gearing

Rockwell Automation Publication PFLEX-RM002D-EN-E - August 2013

53

Detail Drive Configuration and Operation

Chapter 1

Droop

Droop is used to “shed” load and is usually used when a soft coupling of two

motors is present in an application. The master drive speed regulates and the

follower uses droop so it does not “fight” the master. The input to the droop

block comes from the torque output of the speed regulator before limiting. The

output of the droop block reduces the speed reference. Parameter 86

[Spd Reg Droop] sets the amount of base motor speed that the speed reference is

reduced when at full load torque. [Spd Reg Droop] is in units of per unit torque/

per unit speed. For example, when [Spd Reg Droop] is set to 0.1 and the drive is

running at 100% rated motor torque, the droop block would subtract 10% from

the speed reference.

Dynamic Braking

See Bus Regulation/Braking on page

.

This module contains a second order thermal model of the internal. For resistor

sizing, refer to the PowerFlex Dynamic Braking Resistor Calculator Selection

Guide, publication

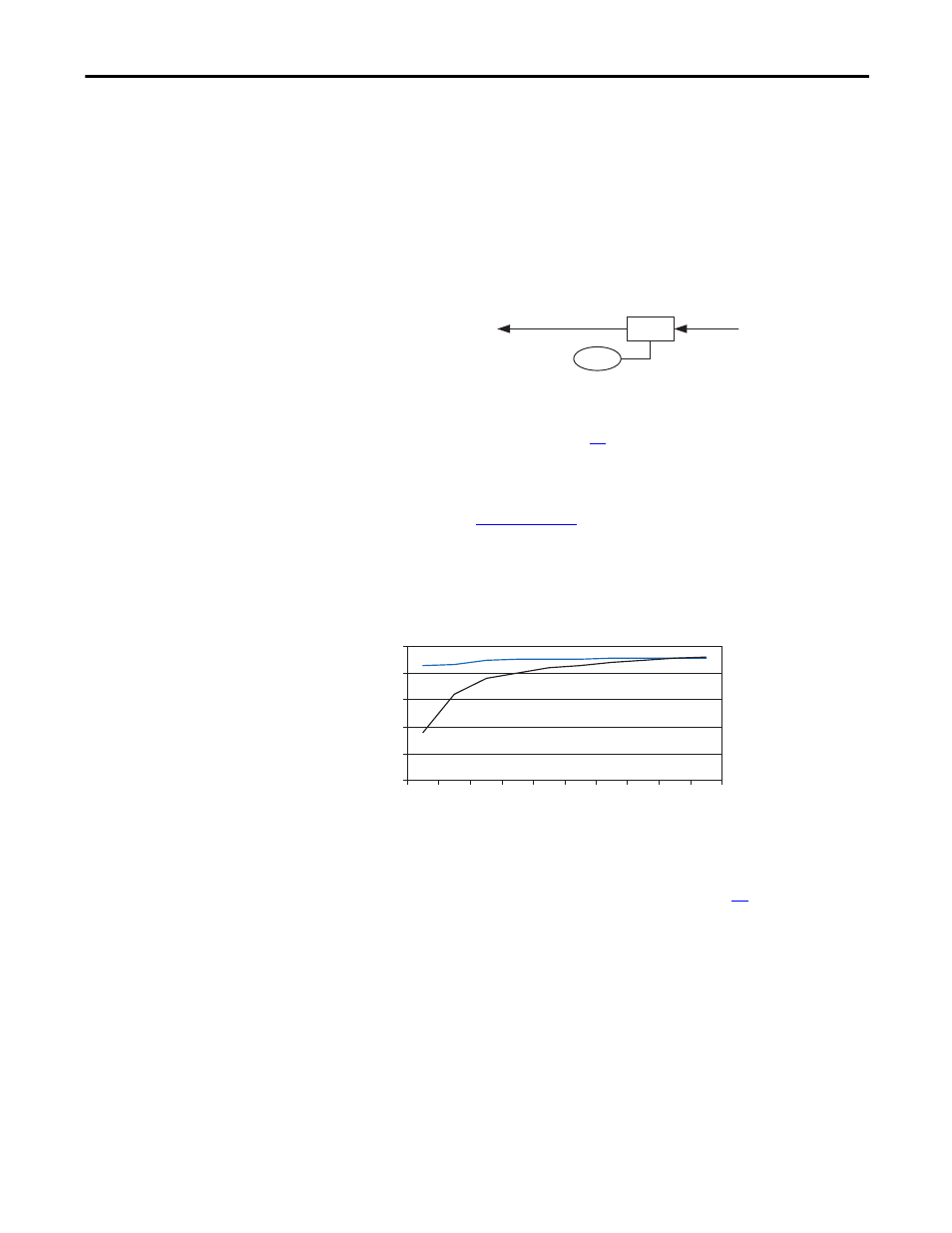

Efficiency

The following chart shows typical efficiency for PWM variable frequency drives,

regardless of size. Drives are most efficient at full load and full speed.

Electronic Gearing

See Position Loop - Follower (Electronic Gearing) on page

86

Droop

Spd Reg Droop

10

20

30

40

50

60

70

80

90

100

% Speed/% Load

% Efficiency

vs. Speed

vs. Load

75

80

85

90

95

100