Rockwell Automation 20D PowerFlex 700S with Phase I Control Reference Manual User Manual

Page 144

144

Rockwell Automation Publication PFLEX-RM002D-EN-E - August 2013

Chapter 1

Detail Drive Configuration and Operation

Hi-Resolution Encoder Feedback Option

The position feedback (seen in [FB Opt0 Posit]) from a Hi-Resolution Encoder

counts at a rate of 1,048,576 counts per motor revolution.

Parameter 259 [Hi Res0 Config] is used to configure the Hi-Resolution Encoder.

•

Bit 5 “Hi Res Dir” determines counting direction. If clear, direction is

forward or up. If set, the direction is reverse or down.

•

Bits12 “SmplRate baits “SmplRate bt3” configure the sample interval for

measuring speed (see

Table 10

). Increasing the encoder sample interval

improves speed measurement near zero speed. Decreasing allows the speed

control regulator to perform with high gains at high speeds.

•

The remaining bits are reserved (not used).

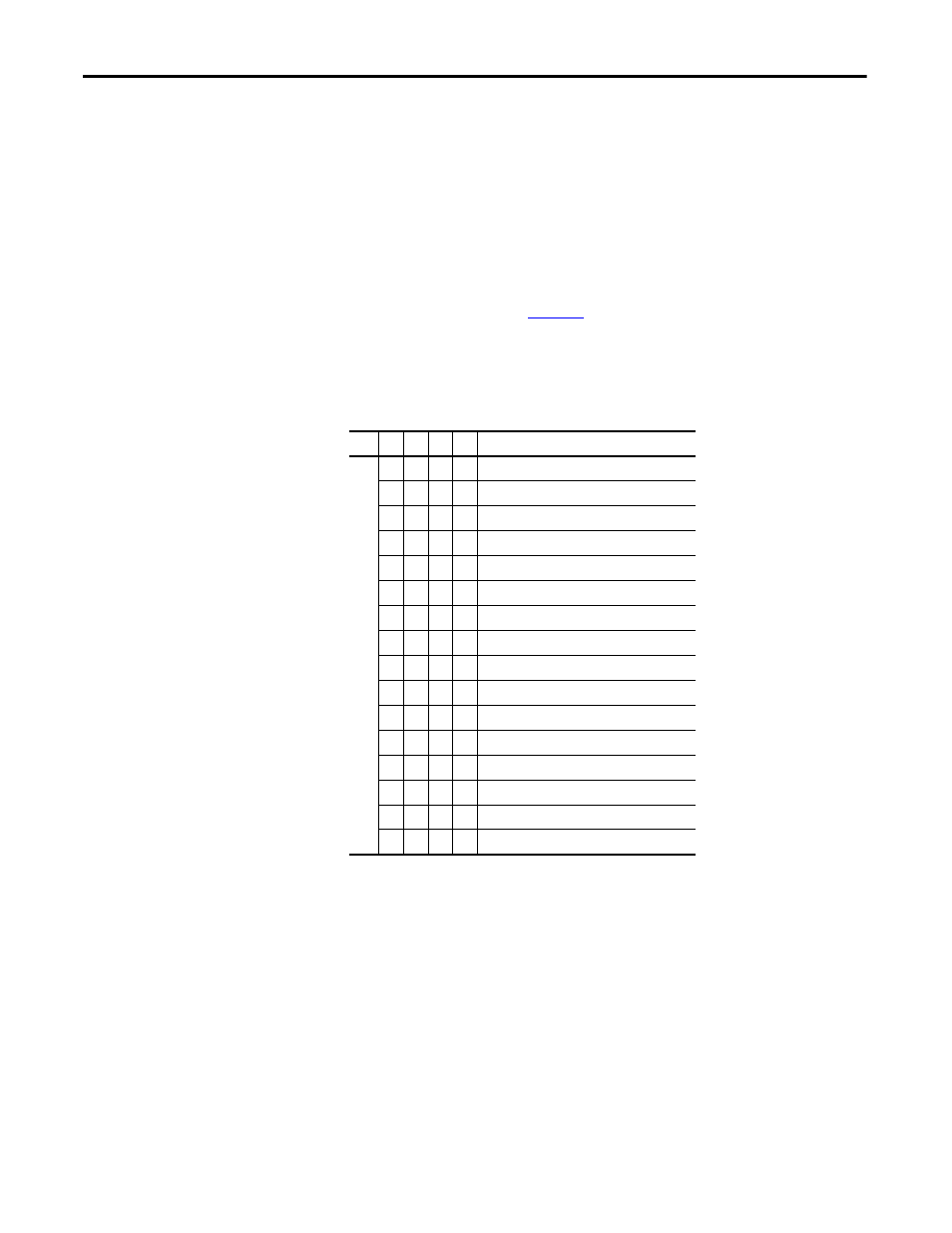

Table 10 - Encoder Sample Interval

Parameter 260 [Hi Res0 Status] indicates faults on the Hi-Resolution Encoder

Feedback Option.

•

Bit 8 “Open Wire” indicates an open wire fault.

•

Bit 9 “Power Fail” indicates the failure of the power supply.

•

Bit 10 “Diag Fail” indicates the option board failed its power-up diagnostic

test.

•

Bit 11 “Msg Checksum” indicates a message checksum fault.

•

Bit 12 “Time Out Err” indicates a RS-485 time-out fault.

•

The remaining bits are reserved (not used).

Bit

15

14

13

12

Encoder Sample Interval Settings

0

0

0

0

0.5 ms

0

0

0

1

0.5 ms (min. setting)

0

0

1

0

1.0 ms

0

0

1

1

1.5 ms

0

1

0

0

2.0 ms (default setting)

0

1

0

1

2.5 ms

0

1

1

0

3.0 ms

0

1

1

1

3.5 ms

1

0

0

0

4.0 ms

1

0

0

1

4.5 ms

1

0

1

0

5.0 ms

1

0

1

1

5.5 ms

1

1

0

0

6.0 ms (max. setting)

1

1

0

1

6.0 ms

1

1

1

0

6.0 ms

1

1

1

1

6.0 ms