8 - troubleshooting and maintenance, Objectives, Troubleshooting recommendations – Rockwell Automation 2707-M232P3_M485P3 DTAM Micro Operator Interface Module User Manual

Page 75: Troubleshooting and maintenance

A–B

8

Chapter

8–1

Troubleshooting and Maintenance

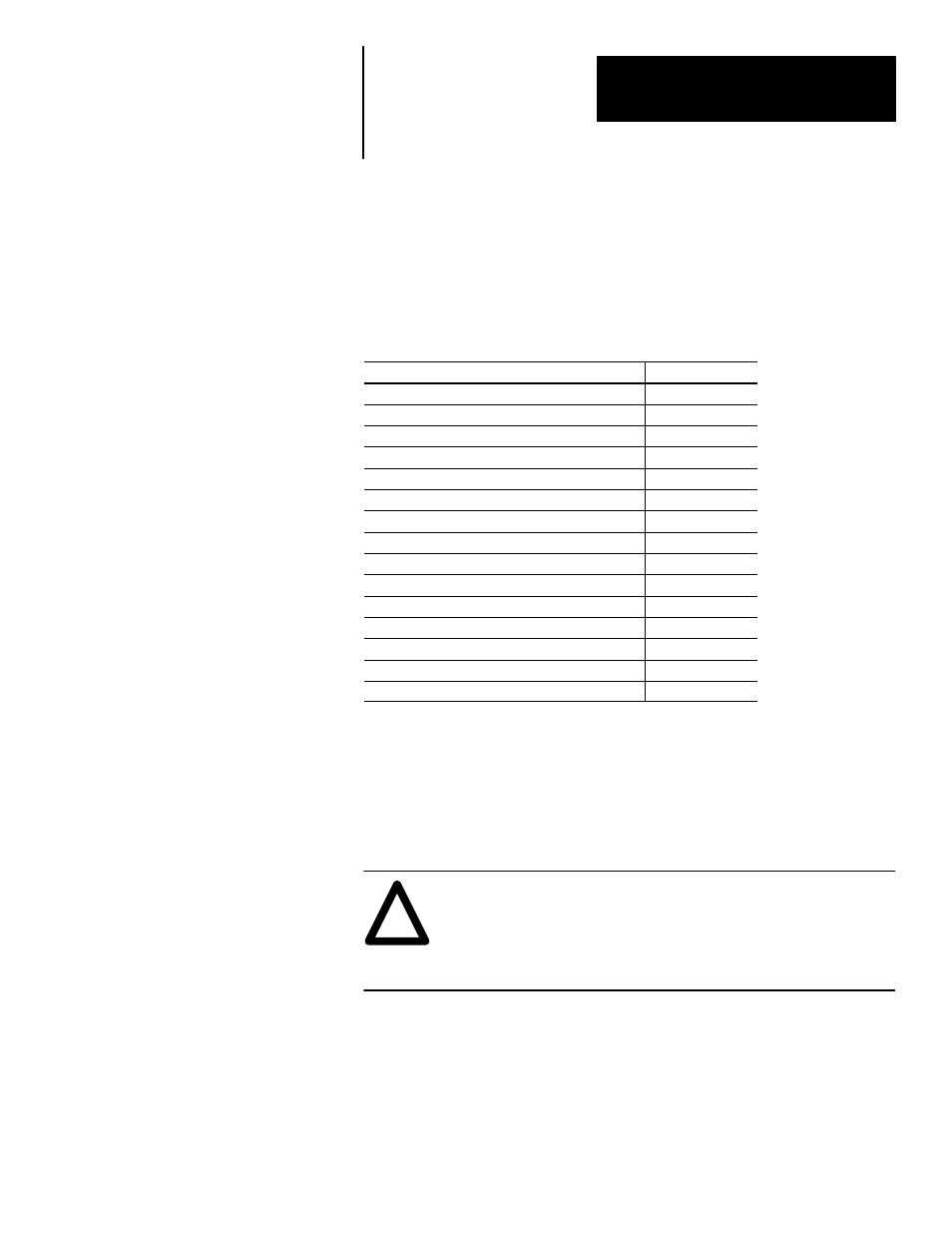

This chapter describes how to isolate and correct the most common

operating problems and routine maintenance tasks. It contains these sections:

Section

Page

Troubleshooting Recommendations

8–1

Equipment Required

8–1

Common Operating Problems

8–2

Error Messages

8–2

Communication Error Codes

8–4

Using the Test Functions

8–5

DIP Switch Test

8–6

Display Test

8–7

Keyboard Test

8–8

Communication Port Test

8–9

RAM Test

8–10

System Memory Test

8–10

Program Memory Test

8–11

TXEN Test

8–12

Cleaning the display window

8–13

Most errors are accompanied by an error message. Find the error message in

the error message listing and perform the recommended corrective action.

If you encounter a problem that is not listed in the table, contact your local

Allen-Bradley distributor for assistance.

!

ATTENTION: Make sure that no objects are inserted or fall into

the terminal through the ventilation slots or DIP switch access

hole. Always disconnect power when checking wiring

connections. Failure to take adequate precautions may result in

severe electrical shock or equipment damage.

Other than verifying that the correct power source is connected to the

terminal (use a voltmeter), no electronic diagnostic equipment is required for

troubleshooting.

Chapter Objectives

Troubleshooting

Recommendations

Equipment Required