2 - dtam micro overview, Objectives, General information – Rockwell Automation 2707-M232P3_M485P3 DTAM Micro Operator Interface Module User Manual

Page 11: Dtam micro overview, Objectives general information

A–B

2

Chapter

2–1

DTAM Micro Overview

This chapter describes the DTAM Micro and accessories.

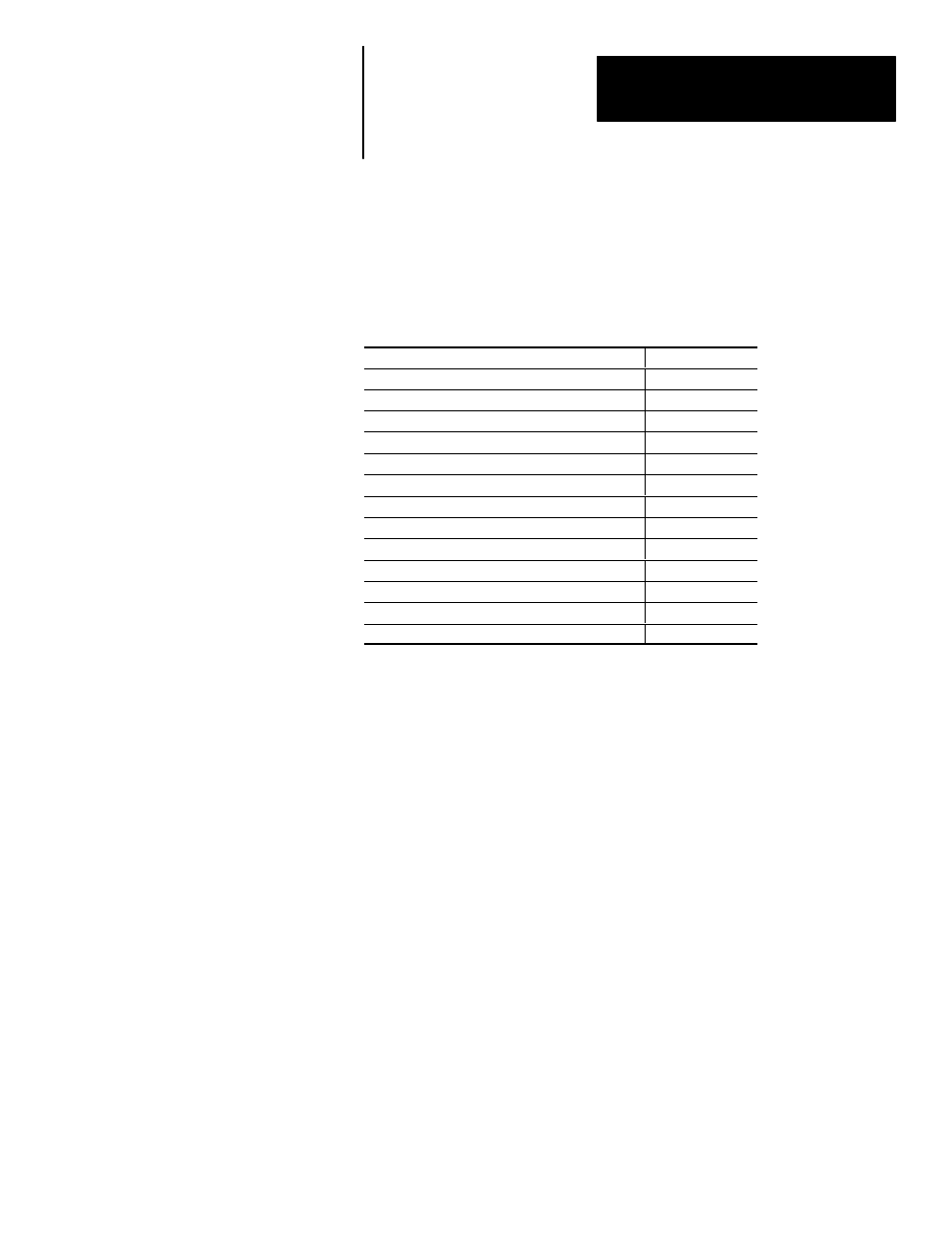

It contains these sections:

Section

Page

General Information

2–1

Package Contents

2–2

Description

2–2

Keypad

2–5

DIP Switches

2–7

Communications Port

2–8

RS-232 Communications

2–9

RS-485 Communications

2–10

Compatibility

NO TAG

Programming the DTAM Micro

2–11

Default Settings

2–12

Product Options

2–13

Product Accessories

2–13

The DTAM Micro interfaces with the PLC-5

and SLC 500

family of

processors. The DTAM Micro allows operators to monitor and manipulate

process data on the plant floor.

RS-232 or RS-485 Port. The DTAM Micro has either an RS-232 port

(Catalog No. 2707-M232P3) or an RS-485 port (Catalog No. 2707-M485P3).

The RS-232 port allows point-to-point connections with a PLC-5 or SLC

5/03, 5/04, 5/05. The RS-485 port provides network or point-to-point

capability with a PLC-5 (over RS-422), SLC or other DH485 device.

Memory Capability. Storage of the PLC-5 DF1 or SLC DH-485 driver

(communications protocol), configuration information, and user-programmed

screens are maintained in nonvolatile memory providing storage for

approximately 244 screens.

Recipe Operations. Recipe type functions allow operators to quickly

modify blocks of data. Download data to a maximum of 10 non-sequential

register addresses per screen. Link multiple recipe screens to download data

to more than 10 addresses.

Flexible Function Key Operations. Eight function keys provide a

convenient way to trigger screen displays and change display screens.

Point-Access/Display Function. Allows you to monitor or modify data files

in SLC or PLC controllers. Use this function to setup and debug application

programs.

Objectives

General Information