1794-oe8h calibration flowchart procedure -18, 1794-oe8h calibration flowchart procedure 5-18 – Rockwell Automation 1794-OE8H FLEX I/O HART Analog Modules User Manual User Manual

Page 86

Publication 1794-UM063A-EN-P - March 2006

5-18 Calibrate Your Module

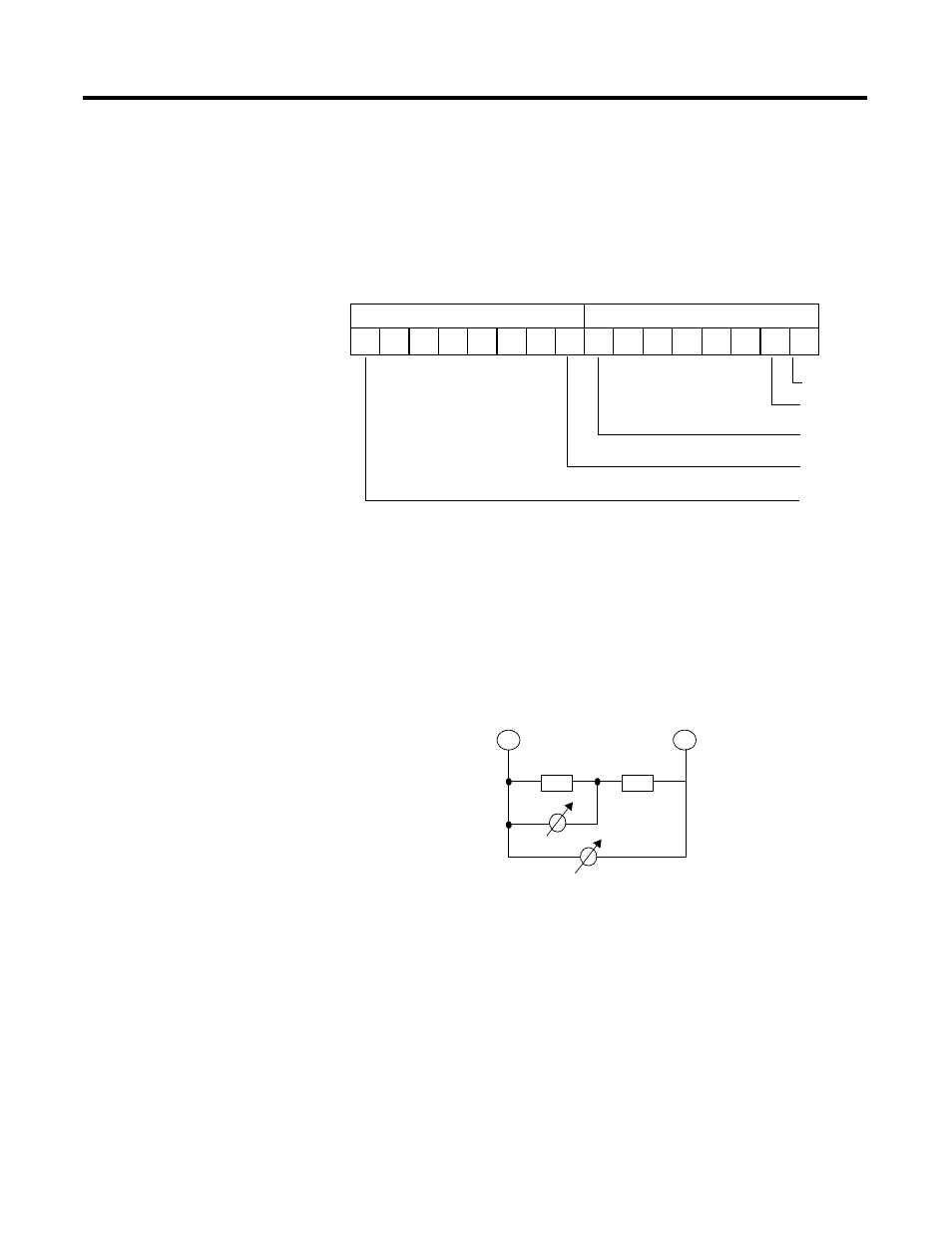

1794-OE8H Calibration Item Byte Value Identifier 48 (Status Mask

Calibration)

Each bit of the lower byte of this word corresponds to one channel. A logical 1

within the lower byte of the words means that this channel is completely

calibrated. A logical 0 means that this channel is not completely calibrated. In

an attempt to write the upper byte of this word, write 0x00h. In an attempt to

read the upper byte of this word, 0x00h is given back.

1794-OE8H Calibration Flowchart Procedure

Perform the calibration at ambient room temperature, 25(±5) °C, according to

the procedure flowchart. Each channel is calibrated one after the other. The

current is measured indirectly via a precision voltmeter placed across a

precision 100 W resistor.

Before all values are completely calibrated, a calibration error is displayed

within the Real Time Data field in the diagnostic status field. After calibration

is complete, the I/O module stores the calibrated values in the RAM area.

Therefore, you must send a store command to cause the I/O module

totransfer the RAM content to the EEPROM Therefore, you must send a

store command to cause the I/O module totransfer the RAM content to the

EEPROM.

15

14

13

12

11

10

9

8

Channel 0

7

6

5

4

3

2

1

0

Reserved

Offset

Channel 1

:

Channel 7

Reserved

Reserved

:

+

-

CHx

100

Ω

650

Ω

Voltmeter

Voltmeter