Tools and equipment, 1794-ie8h calibration features – Rockwell Automation 1794-OE8H FLEX I/O HART Analog Modules User Manual User Manual

Page 70

Publication 1794-UM063A-EN-P - March 2006

5-2 Calibrate Your Module

Tools and Equipment

Use the following tools and equipment to calibrate your analog I/O modules:

1794-IE8H Calibration

Features

The following features are unique to the 1794-IE8H module:

• There are two different values per channel that need to be calibrated:

gain and offset at room temperature (25 °C).

• All values are stored in the I/O module non-volatile EEPROM.

• You can calibrate each channel separately or a specified number of

channels together in respect of one value.

• If an offset value is calibrated, the corresponding gain value is invalid

because the gain value depends on the actual offset value. Therefore,

calibrate the gain values after you calibrate the offset values.

• After calibration, the actual date must be transmitted to the IOM and

stored in the module non-volatile.

• The whole calibration can be set to default values by sending a reset

command. The default date is Jan,01,2000.

• A specified calibration value can be set to default by sending a reset

command for that channel.

• There is a special command to store the whole calibration data from

RAM to EEPROM within the I/O module.

• If one value, except the calibration date, isn’t calibrated yet, or if you set

one value to default, the I/O module displays a calibration error within

the Real Time Data diagnostic field.

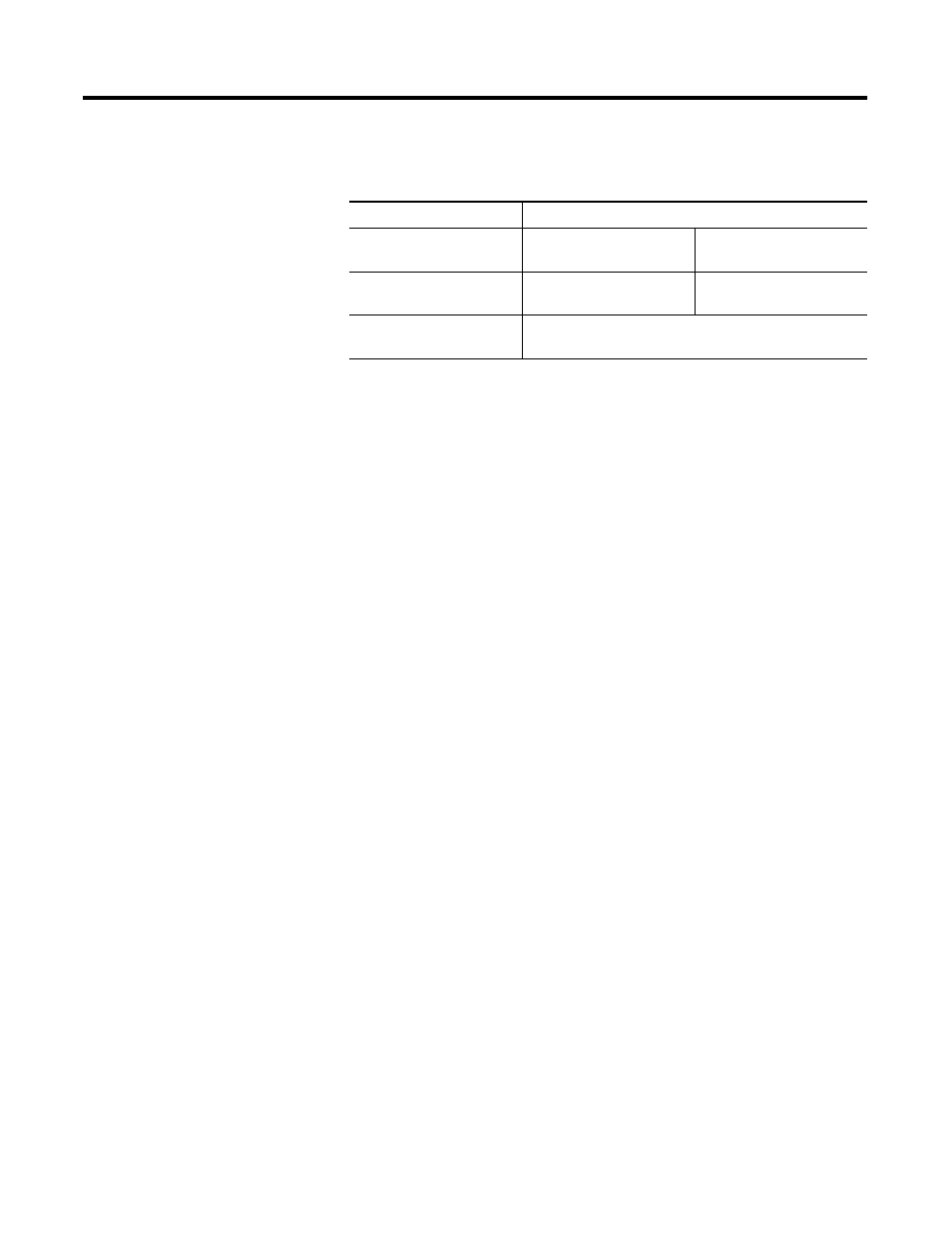

Table 5.1 Tools for Calibration

Tool or Equipment

Description

Precision Current Source

0…22 mA, 0.01 µA

resolution

Used for input modules

Precision Current Meter

0…22 mA, 0.01 µA

resolution

Used for output modules

Industrial Terminal and

Interconnect Cable

Programming terminal for A-B family processors