Direction sensor mode – Rockwell Automation 1771-CFM,D17716.5.99 CONFIGURABLE FLOWMET User Manual

Page 48

4–14

Configure the CFM Module

Publication 1771Ć6.5.99 - December 1995

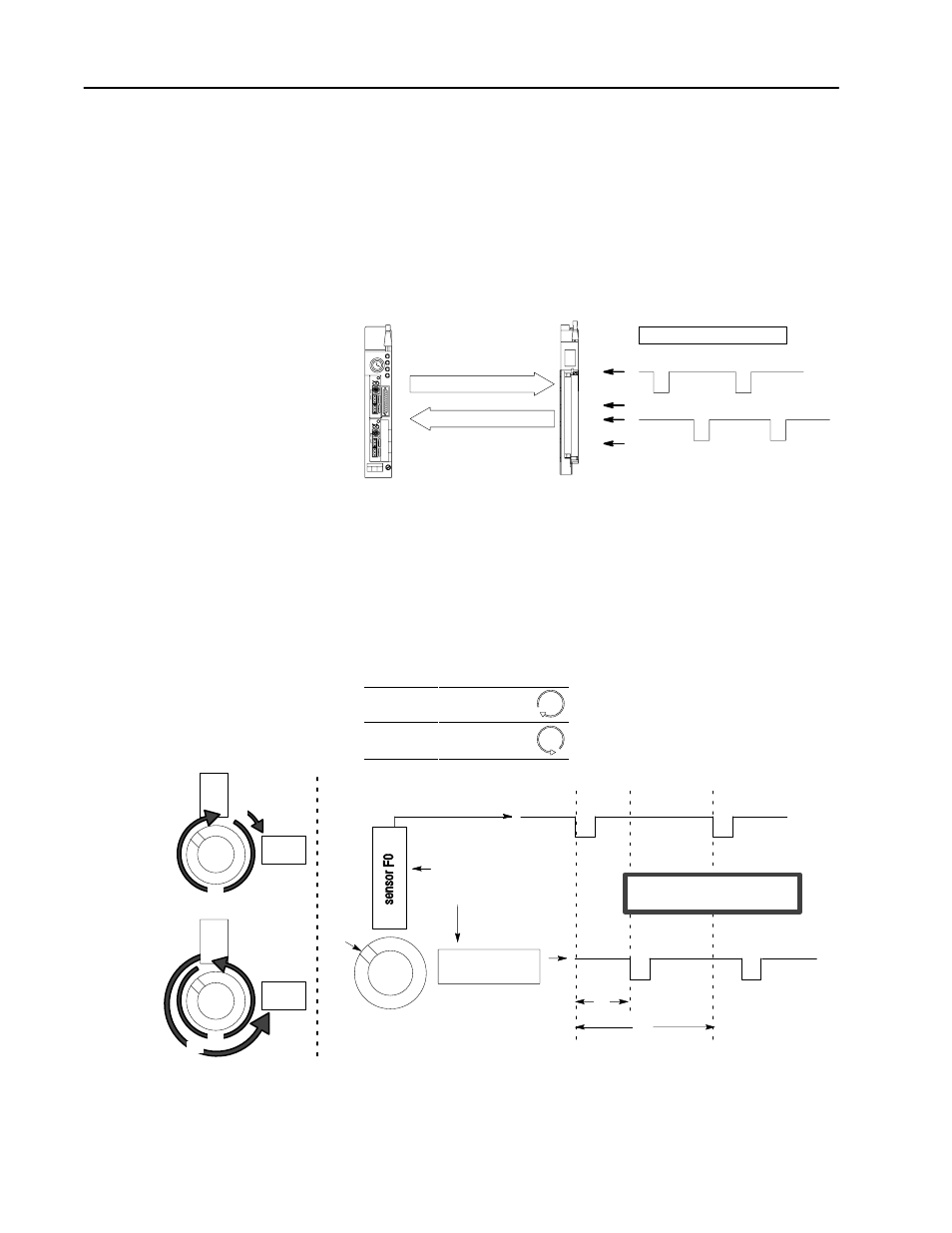

Direction Sensor Mode

Use this mode to measure shaft direction. In this mode, the

CFM module calculates:

•

rate of input (0-100,000Hz)

•

acceleration value

•

direction of shaft

BTR status and input data

1771ĆCFM

F0

G0

F1

G1

not used

not used

BTW configuration

PLC processor

uses channels 0&1 or 2&3

F0 & F1 used in TTL

Frequency Sampling

In this mode, frequency samples are taken every revolution by

measuring A and B:

A = the time between F0 input channel pulses (determines shaft frequency)

B = the time between F0 and F1 input channel pulses (determines shaft direction)

If

Direction is

B

< 1/2 A

clockwise

B

> 1/2 A

counterclockwise

low true signal

B

A

sensor F1

shaft

low true signal

proximity sensors at

F0 and F1 should be

60 to 120

°

apart

notch

F0

F1

F1

shaft

B

F0

A

clockwise

counterclockwise

F1

shaft

B

A

F0

Both sensors cannot be low at

the same time.

Use this mode if you want to determine

shaft direction.

Typical Applications:

•

turbine generators

•

pumps

- 20P PowerFlex DC Drive - Frame D Bimetal Thermostat (10 pages)

- 1336S_F_T_E_R F Frame Snubber Resistor Repl. (6 pages)

- 22-COMM PowerFlex 4-Class DSI (Drive Serial Interface) Network Communication Adapter (4 pages)

- 8-545 Plug In Solid State Relay (2 pages)

- 20-HIM-B1 PowerFlex 7-Class HIM Bezel (DPI) (4 pages)

- 100 Contactors with DC Coil (1 page)

- 100 Contactors with DC Coil (2 pages)

- 20P PowerFlex DC Drive - Frame D Switching Power Supply Circuit Board (6 pages)

- 140G-MTFx_MTHx_MTIx_MTKx Trip Unit Installation-140G-M (6 pages)

- 45BRD Analog Laser Sensor (4 pages)

- 20D Multi-Device Interface Option Board for PowerFlex 700S Drives (20 pages)

- 56RF RFID 18 mm Cylindrical Transceiver (2 pages)

- 42KC Miniature Rectangular: 5V DC Version (2 pages)

- 20P PowerFlex DC Drive - Frame A Switching Power Supply Circuit Board (16 pages)

- 21P-MISC-A-TP-2 Transition Tube Kit #C19-6/7 For PowerFlex 755 w/OEM Liquid Cooling Fr 6/7 Drive (2 pages)

- 42BT Background Suppression Sensor (3 pages)

- 42CB High Speed 18mm Cylindrical (4 pages)

- 140EX-JE2_JE3 Molded Case Circuit Breaker (4 pages)

- 140G-K-EAM1A Early Make Aux Contact for Rotary Handle Oper Mech-140G-K (1 page)

- 140G-K-EAM1A Early Make Aux Contact for Rotary Handle Oper Mech-140G-K (3 pages)

- 20-HIM-A6 PowerFlex (Human Interface Module) (74 pages)

- 42CF General Purpose 12mm Cylindrical (4 pages)

- 20D PowerFlex 700S Phase II Drive Frames 1...6 (80 pages)

- 140EX-HE1_HE2 Molded Case Circuit Breaker (4 pages)

- 140EX-HE1_HE2 Molded Case Circuit Breaker (6 pages)

- 20B PowerFlex 700 Custom Firmware - Pump Off (12 pages)

- 20-WIM-N4S DPI Wireless Interface Module (92 pages)

- 140U H-Frame Circuit Breaker Fixed and Adjustable Thermal Trip (7 pages)

- 140U H-Frame Circuit Breaker Fixed and Adjustable Thermal Trip (2 pages)

- 60-2619, 42JS Swivel/Tilt Mounting Bracket (1 page)

- 22A PowerFlex 4/40/400 Flange Mount (4 pages)

- 45MLA Controller Installation Instructions (16 pages)

- 20P PowerFlex DC Drive - Cooling Fan for Frame A Drives Above 73A at 230V 460V AC (6 pages)

- 42JS Series 7000 to 42JS VisiSight Replacement Kit (2 pages)

- 22A PowerFlex 4-Class HIM Bezel (DSI) (4 pages)

- 42CS Stainless Steel Photoelectric Sensors (4 pages)

- 20L-LL PowerFlex 700L Liquid-to-Liquid Heat Exchanger (40 pages)

- 20P PowerFlex DC Drive - Frame B SCR Modules (20 pages)

- 22B PowerFlex 40 Quick Start FRN 5.xx - 6.xx (161 pages)

- 22B PowerFlex 40 Quick Start FRN 5.xx - 6.xx (22 pages)

- 22F PowerFlex 4M Input RFI Filters (2 pages)

- 45LFM Capacitive Label Sensor (4 pages)

- 140G-Rx Installation Instruction-140G-R (2 pages)

- 140G-Rx Installation Instruction-140G-R (29 pages)

- 22C PowerFlex 400 AC Drive Quick Start - FRN 1-4.xx (28 pages)