Make connections to the field wiring arm – Rockwell Automation 1771-CFM,D17716.5.99 CONFIGURABLE FLOWMET User Manual

Page 26

2–8 Install the CFM Module

Publication 1771Ć6.5.99 - December 1995

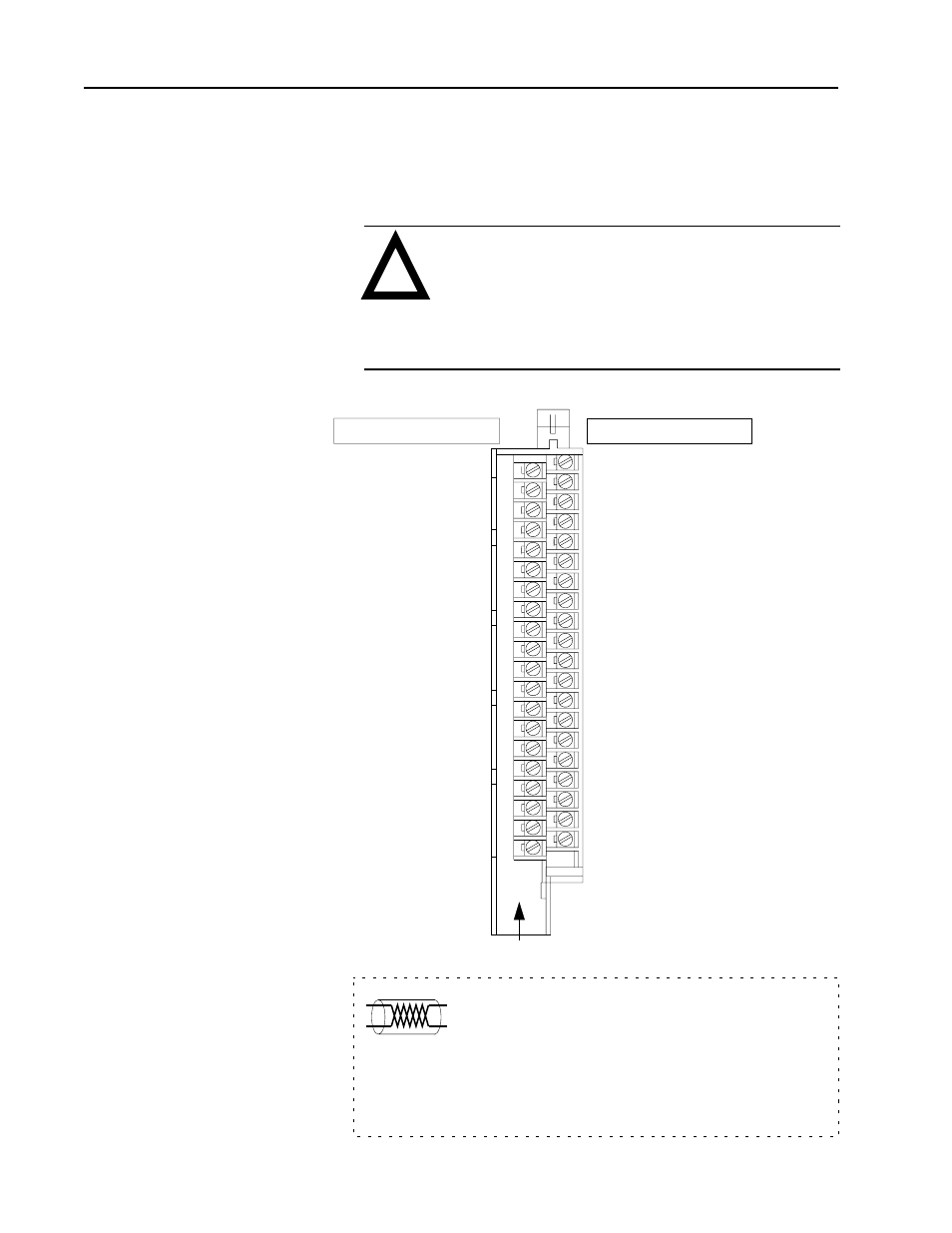

Connect your I/O devices to the 40-terminal field wiring arm

(cat. no. 1771-WN) shipped with the CFM module. Use the wiring

examples on pages 2–9 and 2–10 for additional assistance on

connecting your devices.

!

ATTENTION: Remove power to all I/O devices

before you connect them to the wiring arm. Failure to

remove power from your I/O devices could cause:

•

injury

•

damage to module circuitry

•

equipment damage due to unexpected operation

(See applicable codes and laws.)

actual wiring runs in this direction

10689ĆI

1771ĆWN

Even Numbered Terminals 2Ć40 Odd Numbered Terminals 1Ć39

not used

not used

G0 RET

G1 RET

F0 (500mV)

F0 Input

F1 (500mV)

F1 Input

DC source #1 @ 12mA RET (- proximity pickup)

DC source #2 @ 12mA RET (- proximity pickup)

F2 (500mV)

F2 Input

F3 (500mV)

F3 Input

G2 RET

G3 RET

Output 0

Customer V DC #1 RET (Outputs 0 & 1 RET)

Output 2

Customer V DC #2 RET (Outputs 2 & 3 RET)

Chassis GND

+5V dc RET

G0

G1

F0 (TTL)

F0 RET

F1 (TTL)

F1 RET

+24V DC source #1 @ 12mA

+24V DC source #2 @ 12mA

F2 (TTL)

F2 RET

F3 (TTL)

F3 RET

G2

G3

Customer V DC #1 (5 to 40V)

Output 1

Customer V DC #2 (5 to 40V)

Output 3

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

The sensor cable must be shielded. The shield:

•

must extend the length of the cable, but be connected only at the

1771 I/O chassis

•

must extend up to the point of termination

Important: The shield should extend to the termination point,

exposing just enough cable to adequately terminate the

inner conductors. Use heat shrink or another suitable

insulation where the wire exits the cable jacket.

Make Connections to the

Field Wiring Arm