Rockwell Automation 1336 8A-48A Fiber Industry User Manual

Page 21

2–13

Installation/Wiring

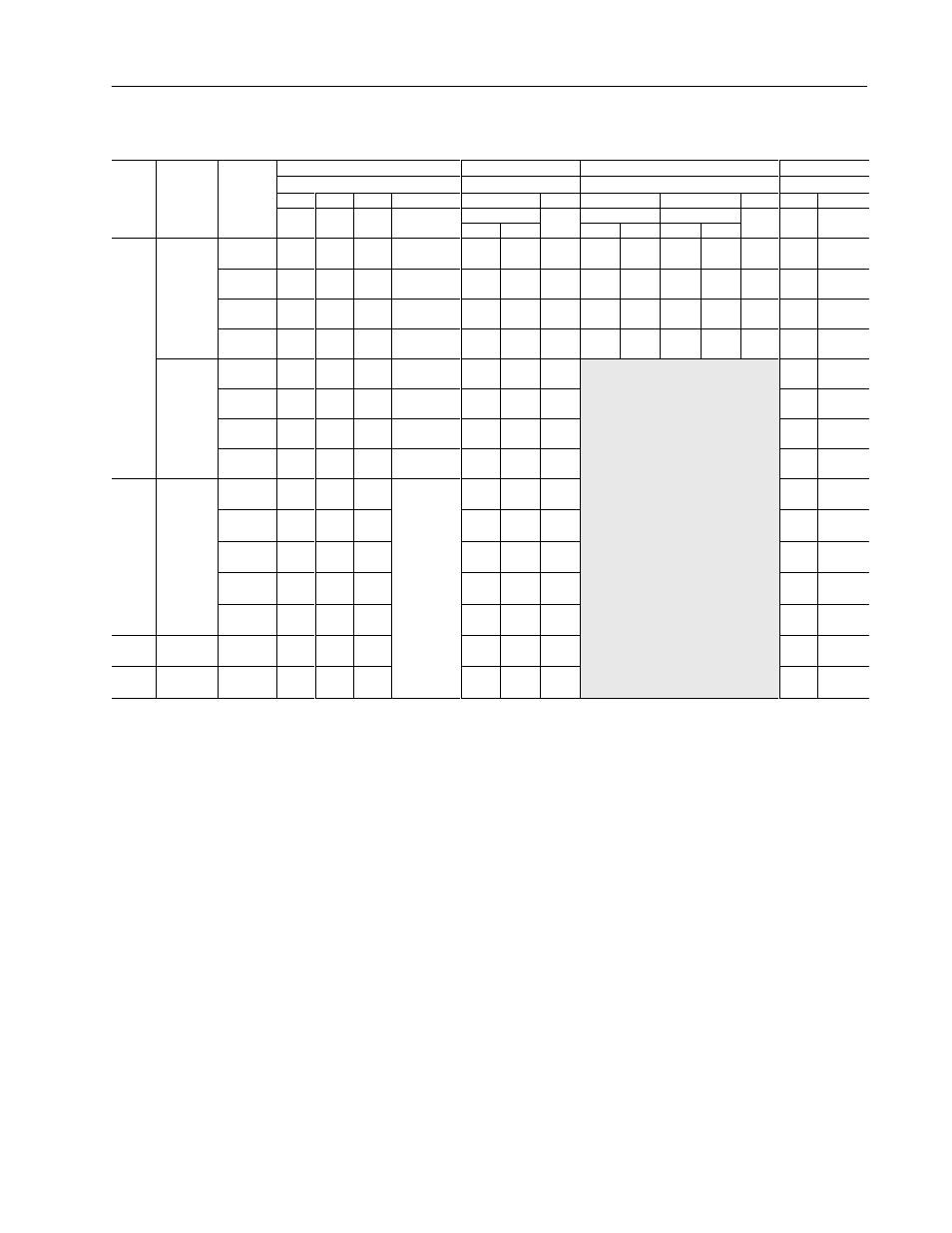

Table 2.D

Maximum Motor Cable Length Restrictions in meters (feet) – 380V-480V Drives

1

No External Devices

w/ 1204-TFB2 Term.

w/ 1204-TFA1 Terminator

Reactor at Drive

2

Motor

Motor

Motor

Motor

A

B

1329

1329R, L

A or B

1329

A

B

1329

A

B or 1329

Drive

Drive kW

Motor kW

Any

Any

Any

Any

Cable Type

Any

Cable Type

Cable Type

Any

Any

Any

Drive

Frame

Drive kW

(HP)

Motor kW

(HP)

Any

Cable

Any

Cable

Any

Cable

Any

Cable

Shld.

3

Unshld.

Any

Cable

Shld.

3

Unshld.

Shld.

3

Unshld.

Any

Cable

Any

Cable

Any

Cable

A2

1.5 (2)

1.5 (2)

7.6

(25)

12.2

(40)

91.4

(300)

91.4

(300)

91.4

(300)

91.4

(300)

91.4

(300)

30.5

(100)

30.5

(100)

91.4

(300)

61.0

(200)

91.4

(300)

22.9

(75)

182.9

(600)

1.2 (1.5)

7.6

(25)

12.2

(40)

114.3

(375)

182.9

(600)

91.4

(300)

182.9

(600)

182.9

(600)

30.5

(100)

30.5

(100)

91.4

(300)

61.0

(200)

182.9

(600)

22.9

(75)

182.9

(600)

0.75 (1)

7.6

(25)

12.2

(40)

114.3

(375)

182.9

(600)

182.9

(600)

182.9

(600)

182.9

(600)

30.5

(100)

30.5

(100)

91.4

(300)

61.0

(200)

182.9

(600)

22.9

(75)

182.9

(600)

0.37 (0.5)

7.6

(25)

12.2

(40)

114.3

(375)

182.9

(600)

182.9

(600)

182.9

(600)

182.9

(600)

30.5

(100)

30.5

(100)

91.4

(300)

61.0

(200)

182.9

(600)

22.9

(75)

182.9

(600)

2.2 (3)

2.2 (3)

7.6

(25)

12.2

(40)

91.4

(300)

91.4

(300)

182.9

(600)

182.9

(600)

182.9

(600)

22.9

(75)

182.9

(600)

1.5 (2)

7.6

(25)

12.2

(40)

114.3

(375)

182.9

(600)

182.9

(600)

182.9

(600)

182.9

(600)

22.9

(75)

182.9

(600)

0.75 (1)

7.6

(25)

12.2

(40)

114.3

(375)

182.9

(600)

182.9

(600)

182.9

(600)

182.9

(600)

22.9

(75)

182.9

(600)

0.37 (0.5)

7.6

(25)

12.2

(40)

114.3

(375)

182.9

(600)

182.9

(600)

182.9

(600)

182.9

(600)

22.9

(75)

182.9

(600)

A3

3.7 (5)

3.7 (5)

7.6

(25)

12.2

(40)

114.3

(375)

Unlimited

Applies to

182.9

(600)

182.9

(600)

182.9

(600)

22.9

(75)

182.9

(600)

2.2 (3)

7.6

(25)

12.2

(40)

114.3

(375)

Applies to

new installa-

tions using

182.9

(600)

182.9

(600)

182.9

(600)

Use 1204-TFB2

22.9

(75)

182.9

(600)

1.5 (2)

7.6

(25)

12.2

(40)

114.3

(375)

tions using

new motors

and new

d i

182.9

(600)

182.9

(600)

182.9

(600)

22.9

(75)

182.9

(600)

0.75 (1)

7.6

(25)

12.2

(40)

114.3

(375)

and new

drives.

For retrofit

182.9

(600)

182.9

(600)

182.9

(600)

22.9

(75)

182.9

(600)

0.37 (0.5)

7.6

(25)

12.2

(40)

114.3

(375)

For retrofit

situations,

check with

182.9

(600)

182.9

(600)

182.9

(600)

22.9

(75)

182.9

(600)

A4

5.5-7.5

(7.5-10)

5.5-7.5

(7.5-10)

7.6

(25)

12.2

(40)

114.3

(375)

check with

the motor

manufactur-

er for insula

182.9

(600)

182.9

(600)

182.9

(600)

24.4

(80)

182.9

(600)

B

5.5-22

(7.5-30)

5.5-22

(7.5-30)

7.6

(25)

12.2

(40)

114.3

(375)

er for insula-

tion rating.

182.9

(600)

182.9

(600)

182.9

(600)

24.4

(80)

182.9

(600)

Type A Motor Characteristics:

No phase paper or misplaced phase paper, lower quality insulation systems, corona inception voltages between 850 and 1000 volts.

Type B Motor Characteristics:

Properly placed phase paper, medium quality insulation systems, corona inception voltages between 1000 and 1200 volts.

1329R Motors:

These AC Variable Speed motors are “Power Matched” for use with Allen-Bradley Drives. Each motor is energy efficient and

designed to meet or exceed the requirements of the Federal Energy Act of 1992. All 1329R motors are optimized for variable speed

operation and include premium inverter grade insulation systems which meet or exceed NEMA MG1. Part 31.40.4.2.

NR = Not Recommended

1

Values shown are for 480V nominal input voltage and drive carrier frequency of 2 kHz. Consult factory regarding operation at carrier frequencies above 2 kHz.

Multiply values by 0.85 for high line conditions. For input voltages of 380, 400 or 415V AC, multiply the table values by 1.25, 1.20 or 1.15, respectively.

2

A 3% reactor reduces motor and cable stress but may cause a degradation of motor waveform quality. Reactors must have a turn–turn insulation rating of 2100

volts or higher.

3

Includes wire in conduit.