MTS Series 793 User Manual

Page 160

MTS Series 793 Tuning and Calibration

Force Sensor Calibration

Calibration Procedures

160

4. Select the Calibration access level.

Standalone FlexTest SE Controllers: Select Config > Access Level >

Calibration

Automated Controllers: In the Station Manager window toolbar, select

Calibration

5. Set up a signal monitor.

See

for more information.

6. Mount the force standard.

7. If you are using Gain/Delta K or Gain/Linearization for calibration, set

initial conditioner calibration values on the Calibration submenu. A typical

complement of ranges could be: 100%, 50%, 20%, and 10% of full scale.

You can create ranges for any percentage of full scale. This creates a sensor

calibration file and sets up any ranges you may want.

Example: Suppose you have an actuator with a full-scale capacity of ±10

kN. You might create ranges for ±10 kN, ±5 kN, ±2.0 kN, and ±1.0 kN.

Note

Some systems do not provide or require multiple ranges, such as those

using full-range conditioners (e.g., Model 493.25 DUC module). In this

case, only one range is used (typically 100%).

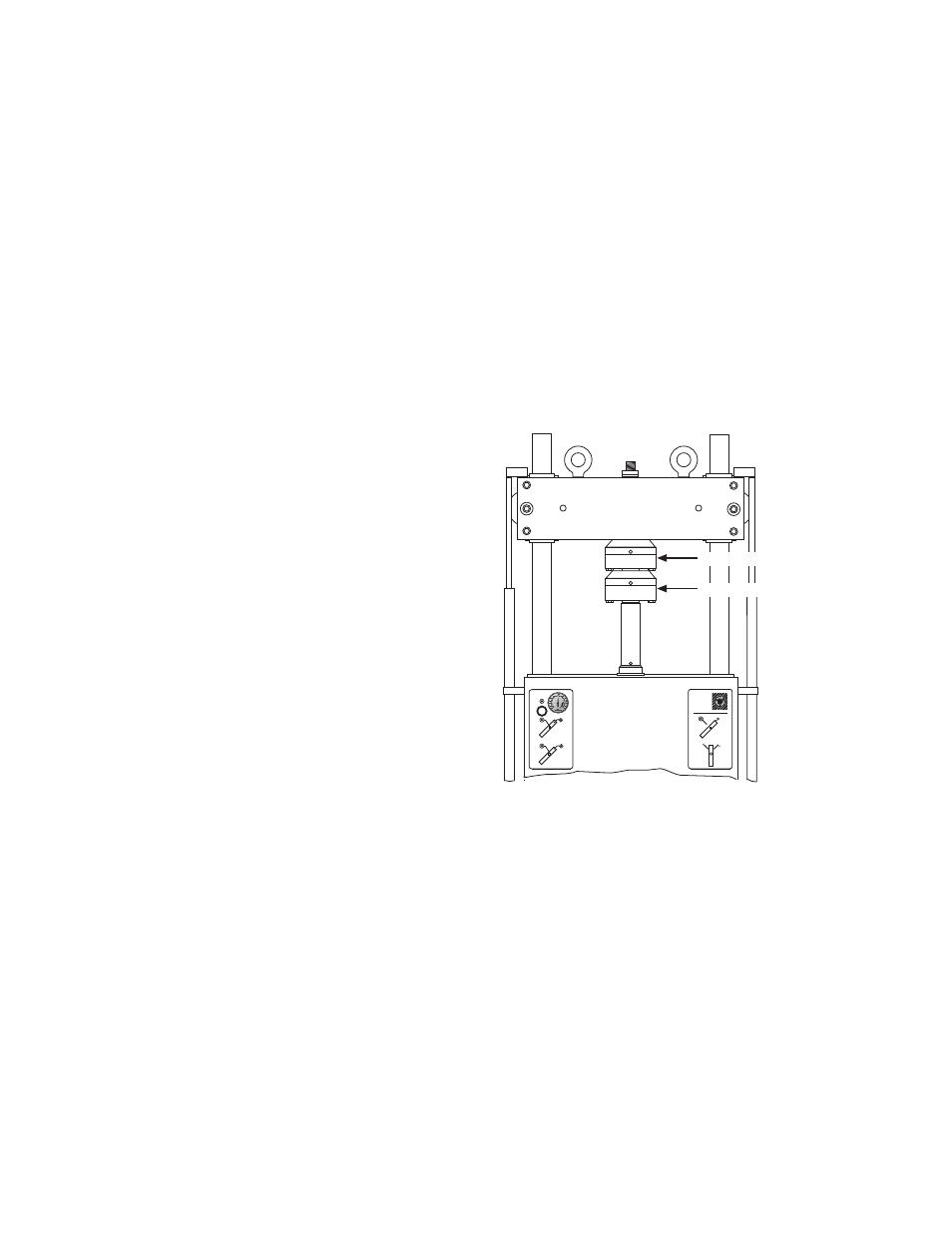

Force Transducer

Load Standard

The illustration shows a load

standard in-line with the

force train coupled with the

force sensor.

The load standard reacts like

a stiff specimen. Be sure the

gain settings (PID) for the

control mode are

appropriate.

If the control mode has not

been tuned yet, use some

default values. Then

recalibrate the sensor after

the initial tuning.