2 troubleshooting, Malfunctions and troubleshooting – Leica Biosystems CV5030 User Manual

Page 91

91

Leica CV5030 – Robotic Coverslipper

8. Malfunctions and Troubleshooting

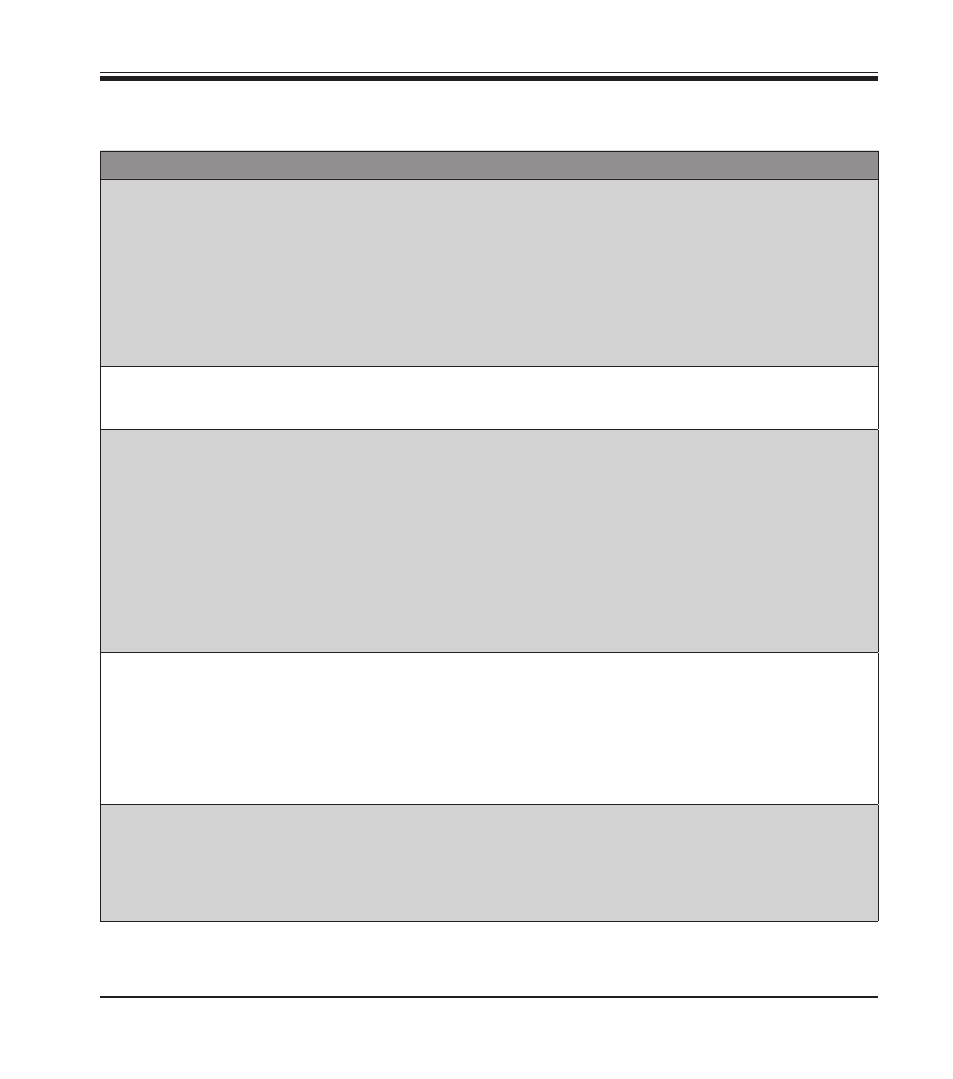

Problem

Possible cause

Remedy

Air bubbles (between

specimen and cover slip).

Air bubbles have developed in the

coverslip mountant from filling the

coverslip mountant bottle.

Observe the coverslip mountant's idle time of approx. 6

to 12 hours after filling the mountant bottle.

Make sure that the coverslip mountant bottle is filled

carefully.

Before the instrument is restarted, check whether the

coverslip mountant is moved out of the dispenser needle

during the priming cycle without bubbles.

At the same time there must not be any more air bubbles in

the hose of the dispenser group (apply coverslip mountant

on an empty specimen slide to check).

Air bubbles (between

specimen and cover slip)

Height of the dispenser needle is

set incorrectly

Set the needle height correctly (

refer to Chapter 4.7.2

).

Check the dispenser needle to see if it is clogged by

glued-on material or bent.

Air bubbles (between

specimen and cover slip).

The dispenser needle is partially

clogged by glued-on material or

otherwise blocked.

Clean the dispenser needle:

Remove the needle from the dispenser and leave it in a

compatible solvent overnight.

To resume working on the instrument, insert a new needle

of the same size and carry out a sufficiently long priming

cycle before the next coverslipping operation.

When reinserting the dispenser needle, always check

the needle height.

Check the dispenser needle cleaner:

Fill this daily with sufficient solvent. Replace the brush of

the dispenser needle cleaner if it has glued-on material

and/or hardening.

Air bubbles (between

specimen and cover slip).

Dispenser needle is bent.

Insert a new dispenser needle of the same size and

carry out a sufficiently long priming cycle before the next

coverslipping operation.

When reinserting the dispenser needle, always check

the needle height.

Check the dispenser needle cleaner: Fill this daily with

sufficient solvent. Replace the brush of the dispenser nee-

dle cleaner if it has glued-on material and/or hardening.

Air bubbles (between

specimen and cover slip).

Glued-on material within the

dispenser group.

Glued-on material from hardened coverslip mountant

in the dispenser group usually cannot be seen. If air

bubbles continue to form despite carrying out the actions

mentioned above, rinse the dispenser group with 100 ml

of a compatible solvent. Do so in accordance with the

instructions in

Chapter 7 – Cleaning and Maintenance

.

8.2 Troubleshooting