22 troubleshooting, Troubleshooting – JLG 4017PS Service Manual User Manual

Page 81

3-43

3706PS, 3707PS, 4014PS, 4017PS, 33.7, 37.6, 37.7

Boom

3.22

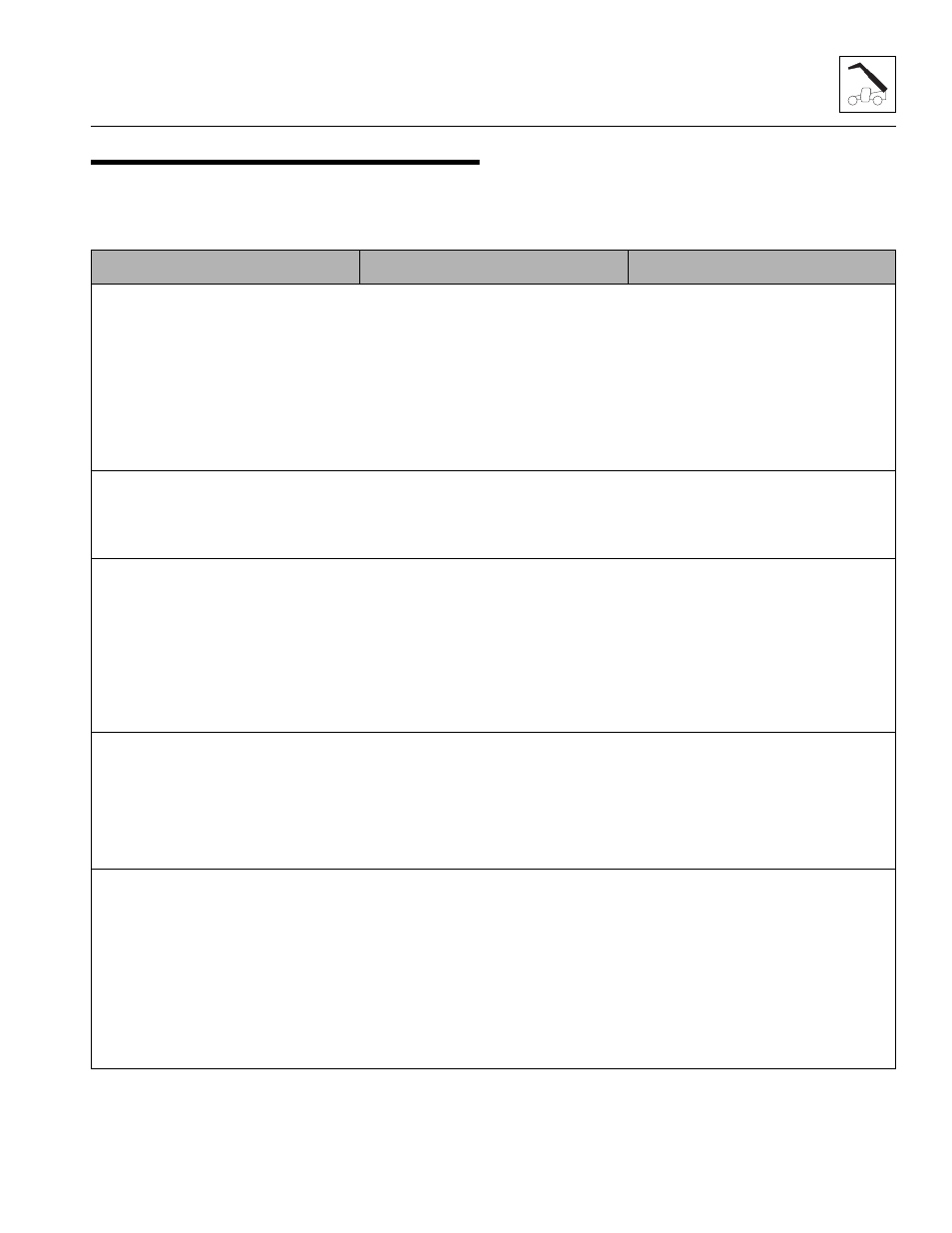

TROUBLESHOOTING

This section provides an easy reference guide covering

the most common problems that occur during operation

of the boom.

Problem

Possible Causes

Remedy

1. Boom will not extend or

retract

1. Broken hydraulic hose(s) or

tube(s) and/or connections

leaking.

1. Locate break, replace hose(s)

or tube(s), tighten connections.

2. Extend/retract hydraulic system

not operating properly.

2. Refer to Section 8.5, “Hydraulic

3. Faulty extend/retract cylinder.

3. Repair cylinder. Refer to Section

8.11.1, “General Cylinder

Removal Instructions.”

2. Boom shifts to right or left

when extending.

1. Boom side wear pads

improperly shimmed or worn.

1. Shim wear pads to correct gap.

Replace wear pads as needed.

Refer to Section 3.17, “Boom

Wear Pads.”

3. Excessive pivot pin noise

and/or wear.

1. Insufficient lubrication.

1. Lubricate at regular intervals.

Refer to Section 2.7,

“Lubrication Schedule.” Replace

worn pins as needed.

2. Worn bearing(s).

2. Replace bearing(s) and

lubricate at regular intervals

Refer to Section 2.7,

“Lubrication Schedule.”

4. Excessive Compensation

cylinder pivot pin noise and/

or wear.

1. Insufficient lubrication.

1. Lubricate at regular intervals.

Refer to Section 2.7,

“Lubrication Schedule.” Replace

worn pins as needed.

2. Worn bushing(s).

2. Replace bushing(s) and

lubricate at regular intervals.

5. Boom will not raise or lower.

1. Broken hydraulic hoses or tubes

and/or connection leaks.

1. Locate break, replace hose(s)

or tube(s), tighten connections.

2. Lift/lower hydraulic system not

operating properly.

2. Refer to Section 8.5, “Hydraulic

3. Faulty lift/lower cylinder.

3. Repair cylinder. Refer to Section

8.11.1, “General Cylinder

Removal Instructions.”

4. Seized boom pivot pin bushing.

4. Replace bushing.