JLG 4017PS Service Manual User Manual

Page 144

Hydraulic System

8-12

3706PS, 3707PS, 4014PS, 4017PS, 33.7, 37.6, 37.7

b. Disassembly

Dispose of the old reservoir according to local regulations

concerning hazardous materials disposal.

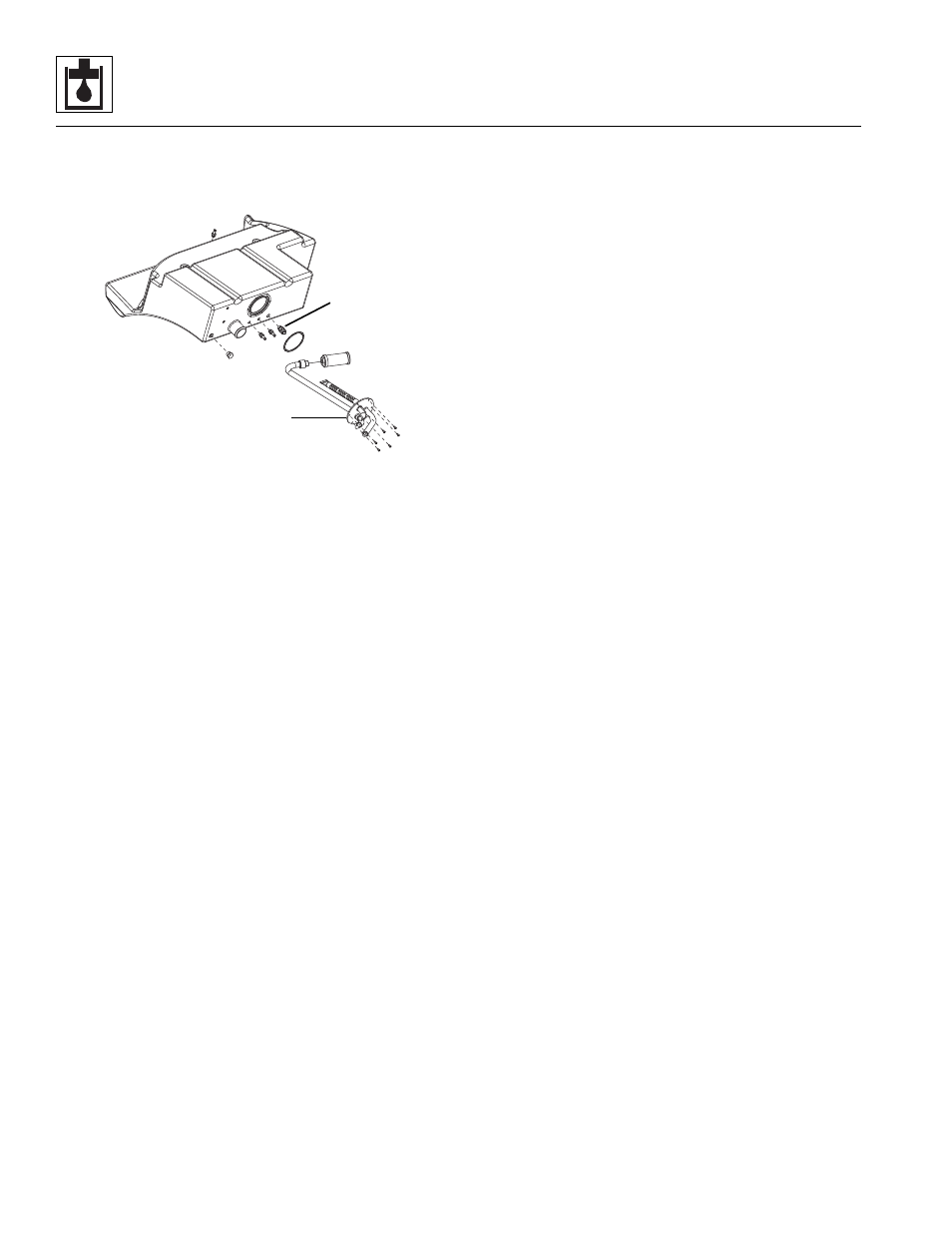

1. Remove the adapters (2) from the bottom of the

tank.

2. Remove the screws securing the hydraulic manifold

(3) to the tank.

3. Pull the hydraulic manifold out of the hydraulic tank.

c. Assembly

1. Install the hydraulic manifold in the hydraulic tank

using a new o-ring. Torque the six screws to

2,25 ±0,25 Nm (19.9 ±2 lb-in).

2. Install the adapters to the bottom of the tank. Torque

to 23±3 Nm (17±2 lb-ft).

d. Cleaning and Drying

If contaminated hydraulic oil or foreign material is in the

tank, the tank can usually be cleaned.

To clean the hydraulic oil reservoir:

1. Have a dry chemical (Class B) fire extinguisher near

the work area.

2. Remove the hydraulic oil reservoir drain plug, and

safely drain any hydraulic oil into a suitable

container. Dispose of hydraulic oil properly.

3. Clean the hydraulic oil reservoir with a high-pressure

washer, or flush the tank with hot water for five

minutes and drain the water. Dispose of

contaminated water properly.

e. Inspection

1. Inspect the hydraulic oil reservoir thoroughly for any

cracks, slices, leaks or other damage.

2. With the hydraulic oil reservoir removed from the

machine, plug all openings except one elbow fitting.

Install the elbow fitting, and apply approximately

7-10 kPa (1-1.5 psi) of air pressure through the

elbow. Check the reservoir for leaks by applying a

soap solution to the exterior and look for bubbles to

appear at the cracked or damaged area.

f.

Reservoir Installation

1. Place the hydraulic oil reservoir into its original

orientation.

2. Secure the hydraulic oil reservoir to the frame with

the previous mounting hardware.

3. Uncap and connect the previously labeled hydraulic

hoses to their appropriate locations. Be sure all lines

are free of kinks and sharp bends.

4. Install hydraulic filter bracket and hydraulic filter.

5. Fill the reservoir with oil until oil level is visible in the

lower gauge window. Refer to Section 2.5, “Fluids,

Lubricants and Capacities.”

6. Check the hydraulic oil reservoir for leaks.

7. Install the lower reservoir cover.

8. Properly connect the battery.

9. Close and secure the engine cover.

10. Start machine and check all hydraulic functions for

proper operation. Check for any hydraulic oil leaks.

Shut machine OFF and check hydraulic oil level. If

oil is warm, oil level should be visible in the upper

gauge window. Add hydraulic oil if necessary.

11. Remove the Do Not Operate Tag from the ignition

key switch and the steering wheel.

MAM1110

2

3