8 second boom section installation, Second boom section installation, Warning – JLG 4017PS Service Manual User Manual

Page 47

3-9

3706PS, 3707PS, 4014PS, 4017PS, 33.7, 37.6, 37.7

Boom

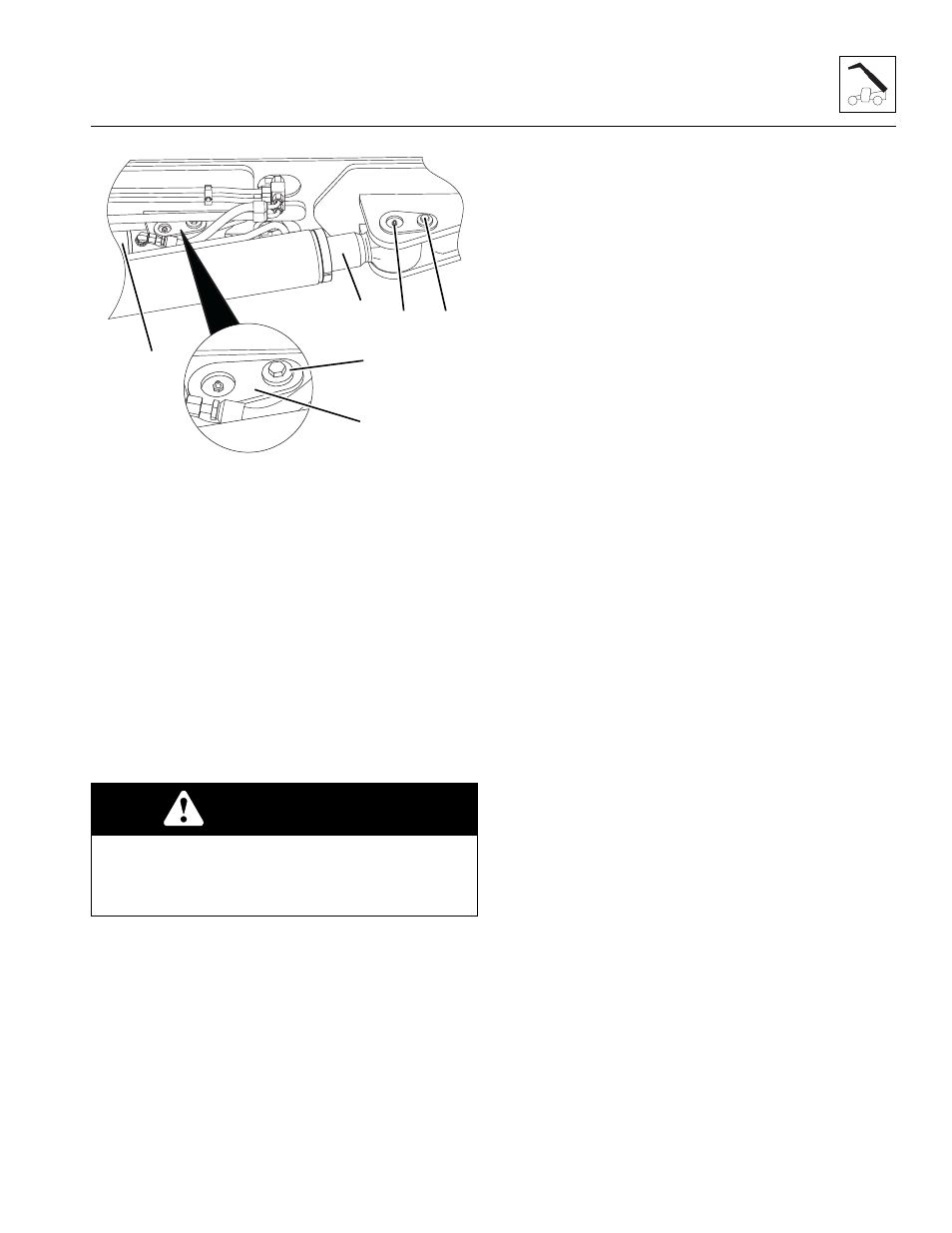

5. With a sling in place, raise the compensation

cylinder (5) into place and install the pin (6) and lock

bolt (7) to the barrel end of the compensating

cylinder on the first boom section.

6. With the sling still in place, install the rod end of the

lift/lower cylinder (8), pin (9) and lock bolt (10). Apply

Loctite

®

242

TM

and torque to 90 Nm (66 lb-ft).

Note: Raising the boom up or down with the sling may

be necessary so the boom, compensating and lift/lower

cylinder bores can be aligned for easier pin installation.

7. Remove sling.

8. Temporarily connect the battery.

9. Start the machine and lower the first boom section to

a level position.

10. Properly disconnect the battery.

3.3.8

Second Boom Section Installation

Note: Light lubrication of the boom wear surfaces with a

factory authorized grease is recommended to keep the

boom wear surfaces lubricated properly. Lubrication of

the boom wear surfaces is also recommended when the

machine is stored, to help prevent rusting.

1. If previously removed, install the extend/retract

cylinder into the rear of the second boom section.

Refer to Section 3.3.6, 3.3.6. “Extend/Retract

Cylinder Installation.”

2. Using suitable slings, balance the second boom

section, lift and carefully guide the boom into place.

3. Install the wear pads, shims and bolts to their proper

location at the front inside of the first boom section.

DO NOT tighten the wear pads at this time.

4. Feed the tilt cylinder hoses and if equipped, the

auxiliary hoses through the channel above the

extend/retract cylinder.

5. Install the wear pads, shims and bolts previously

removed from the rear of the second boom section.

DO NOT tighten the wear pads at this time.

6. Uncap and connect the previously labeled extend/

retract cylinder hoses to the extend/retract cylinder.

Refer to Section 2.3.3, “Hydraulic Hose Torque

Chart,” for proper hose torque.

7. Uncap and connect the previously labeled tilt hoses

and (if equipped) auxiliary hoses to the appropriate

cylinder. Refer to Section 2.3.3, “Hydraulic Hose

Torque Chart,” for proper hose torque.

8. Install the boom angle sensor arm. Refer to Section

9. Adjust and shim each wear pad as needed. Refer to

Section 3.17, “Boom Wear Pads.”

10. Properly connect the battery.

11. Start the engine and operate all boom functions

several times to bleed any air out of the hydraulic

system. Check for fluid leaks. Check the hydraulic

fluid level in the tank and add fluid as required.

12. Clean up all debris, hydraulic fluid, etc., in, on, near

and around the machine.

13. Close and secure the engine cover.

14. Remove the Do Not Operate Tag from the ignition

key switch and the steering wheel.

WARNING

DO NOT activate ANY boom function other than the

boom lift/lower function. Activating the extend/retract,

tilt or auxiliary function could cause hydraulic oil to

spray onto the machine and/or surrounding areas.

MAM0640

7

6

5

8

9

10