4 lsi-can check pt, Lsi-can check pt, Section 9.16.4, “lsi-can check pt – JLG 4017PS Service Manual User Manual

Page 204

Electrical System

9-46

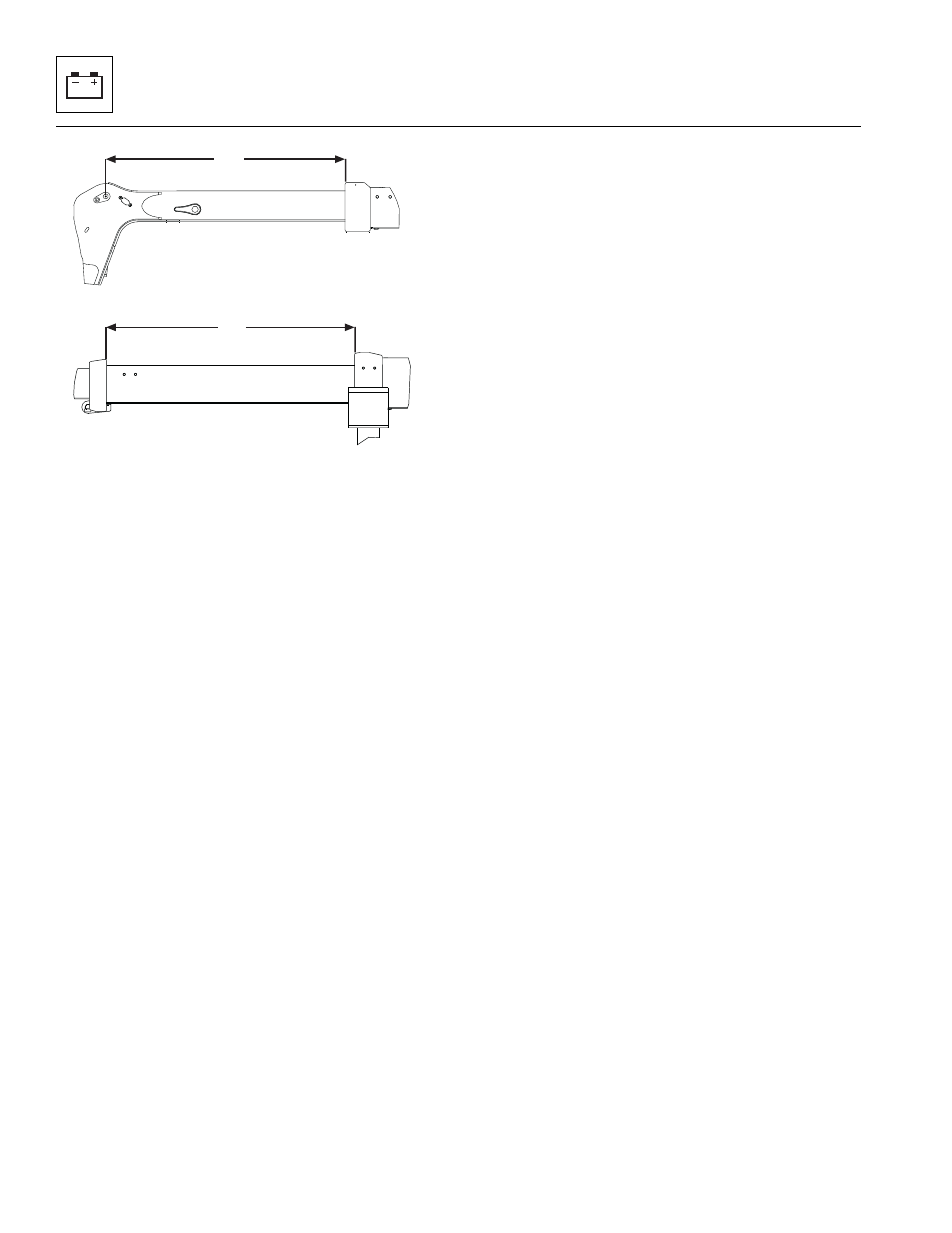

3706PS, 3707PS, 4014PS, 4017PS, 33.7, 37.6, 37.7

8. With the boom horizontal, slowly extend the boom to

the distance of Xcal (2). The proper calibration

weight is now on the rear axle and the LSI can now

be calibrated.

9. Press the SYSTEM CHECK button on the LSI

display and release. As the calibration point is

recorded, buzzer sounds and the LEDs will flash and

perform a sequence until all are flashing.

10. Perform the LSI- CAN Check PT to finalize the

calibration. Refer to Section 9.16.4, “LSI-CAN Check

PT.”

Note: The following procedure MUST BE performed to

finalize the LSI System Calibration.

9.16.4

LSI-CAN Check PT

With the LSI calibrated, the UGM also needs calibrated

and verified.

1. The machine must be on a level surface, wheels

steered straight and park brake ON.

2. Start the machine.

3. Press the “C” and “OK” buttons simultaneously on

the keypad or the analyzer.

4. Go to “ACCESS LEVEL 3” and press “OK”.

5. Enter the proper access code and press “OK”.

6. “ACCESS LEVEL 2” is now visible.

7. Go to “CALIBRATIONS” menu, press “OK”.

8. Scroll to “LSI_CAN CHECK PT”.

9. “SET LSI_CAN CHECK POINT”, use the arrow keys

to change “NO” to “YES”.

10. Follow and execute the screen instructions:

a. “Remove Weights and Attachments”, press “OK”.

b. 4014PS and 4017PS ONLY: “Fully deploy

stabilizers”, press “OK”.

c. “TELESCOPE IN and FULLY LIFT UP”, press

“OK”.

d. “STOP, WAIT ONE MINUTE”, wait at least one

minute and press “OK”.

e. “PRESS ENTER TO SET CHECK POINT”, press

“OK”

f. Screen defaults back to “CALIBRATIONS:

LSI_CAN CHECK POINT”.

g. Press “C” for approximate two seconds to return

to normal display screen.

h. LSI Can Check is now complete.

11. Return machine to service.

A

B

C

MAM1480

A

B

C

D

2

2

3706PS, 3707PS, 33.7, 37.6 & 37.7

4014PS and 4017PS