2 axle installation, Axle installation – JLG 4017PS Service Manual User Manual

Page 100

Axles, Drive Shafts, Wheels and Tires

5-4

3706PS, 3707PS, 4014PS, 4017PS, 33.7, 37.6, 37.7

6. If the axle will be disassembled after removal, place

a suitable receptacle under the axle (1) and wheel

hubs (3) drain plugs. Remove the drain plugs and

allow the oil to drain into the receptacle. Transfer the

used oil into a suitable covered container, and label

the container as “Used Oil.” Dispose of the used oil

at an approved recycling facility.

7. Label, disconnect and cap the steering and brake

lines at the axle. Wipe up any spilled oil.

8. Block the front and rear of both tires on the axle that

is not being removed. Ensure that the machine will

remain in place during axle removal before

proceeding.

9. Raise the machine using a suitable jack or hoist.

Place suitable supports under both sides of the

frame and lower the machine onto the supports.

Ensure that the machine will remain in place during

axle removal.

10. Support the axle that is being removed with a suitable

jack, hoist or overhead crane and sling. DO NOT

raise the axle or the machine.

11. Remove both wheel and tire assemblies from the

axle that is being removed. Refer to Section 5.11.1,

“Removing Wheel and Tire Assembly from

Machine.”

Note: The wheel and tire assemblies must be re-installed

later with the directional tread pattern “arrows” facing in

the direction of forward travel.

12. Remove the drive shaft assembly. Refer to Section

5.10.3, “Drive Shaft Removal.”

13. 4014PS & 4017PS Only: On the front axle, remove

the lower position cylinder mount pin for the front

cylinder. Tap the cylinder mount pin out, and move

the cylinder to prevent it from interfering with axle

removal. If a new axle will be installed, remove the

frame level mounting plate from the axle.

14. Remove the bolts and locknuts securing the axle to

the frame.

15. Remove the axles from the machine using the jack,

hoist or overhead crane and sling supporting the

axle. DO NOT raise or otherwise disturb the

machine while removing the axle. Balance the axle

and prevent it from tipping, turning or falling while

removing it from beneath the machine. Place the

axle on a suitable support or holding stand.

5.4.2

Axle Installation

1. Before proceeding, ensure that the machine will

remain in place during axle installation. Block the

front and rear of both tires on the axle that is already

installed on the machine.

2. If applicable, raise the machine using a suitable jack

or hoist. Place suitable supports beneath the frame

and lower the machine onto the supports, allowing

enough room for axle installation. Ensure that the

machine will remain in place during axle installation.

3. Using a suitable jack, hoist or overhead crane and

sling, remove the axle from its support or holding

stand. Balance the axle and prevent it from tipping,

turning or falling while positioning it beneath the

machine. DO NOT raise or otherwise disturb the

machine while installing the axle. Keep the axle

supported and balanced on the jack, hoist or

overhead crane and sling throughout the installation

procedure.

4. Position the axle under the frame, and align the axle

housings with the holes in the frame.

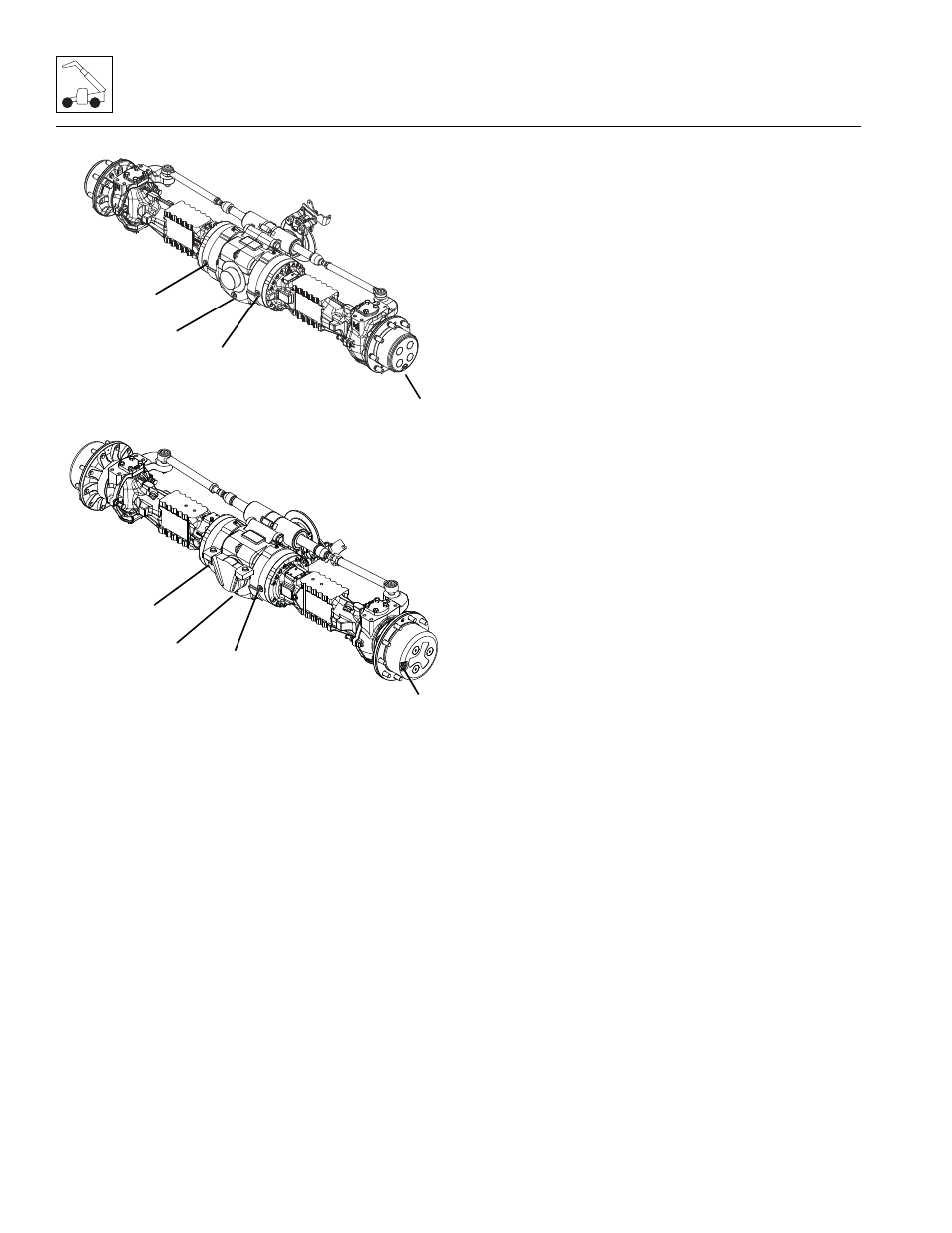

MZ2491

2

3706PS, 3707PS, 33.7, 36.7 & 37.7 FRONT

AXLE

3

1

2

MECHANICAL PARK BRAKE SHOWN

MZ2501

1

4014PS & 4017PS FRONT AXLE

3

2

2

MECHANICAL PARK BRAKE SHOWN