10 drive shafts, 1 drive shaft inspection, 2 drive shaft maintenance – JLG 4017PS Service Manual User Manual

Page 108: 3 drive shaft removal, 4 drive shaft cleaning and drying, 5 drive shaft installation, Drive shafts, Drive shaft inspection, Drive shaft maintenance, Drive shaft removal

Axles, Drive Shafts, Wheels and Tires

5-12

3706PS, 3707PS, 4014PS, 4017PS, 33.7, 37.6, 37.7

5.10

DRIVE SHAFTS

5.10.1

Drive Shaft Inspection

Inspect areas where the drive shaft flange yokes and slip

yokes mount to the drive shafts. Attempt to turn each

drive shaft in both directions. Look for excessive

looseness, missing parts, cracks or other damage. Worn

or damaged drive shafts and cross and bearing

assemblies may cause an excessive amount of vibration

or noise.

Note: To ensure optimum performance, the driveshaft

assemblies are specially balanced as a unit at the

factory. When servicing any flange yoke, slip yoke or

drive shaft tube, order a complete assembly if

components are bent or damaged. Refer to the

appropriate parts manual for ordering information.

Note: Any bolt removed from the drive shaft assembly

MUST be replaced. Do Not re-torque.

5.10.2

Drive Shaft Maintenance

Refer to Section 2.5, “Fluids, Lubricants and Capacities,”

for information regarding the lubrication of the grease

fittings on the drive shafts.

5.10.3

Drive Shaft Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the transmission control lever in (N) NEUTRAL,

engage the park brake and shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and steering wheel.

3. Open the engine cover. Allow the system fluids to

cool.

4. Properly disconnect the battery.

5. Block the wheels.

6. The drive shaft assembly is a balanced assembly.

Mark the yoke and axle, transmission and the shaft

and slip yoke so that these components can be

returned to their original positions when reinstalled.

Yokes at both ends of the drive shaft must be in the

same plane to help prevent excessive vibration.

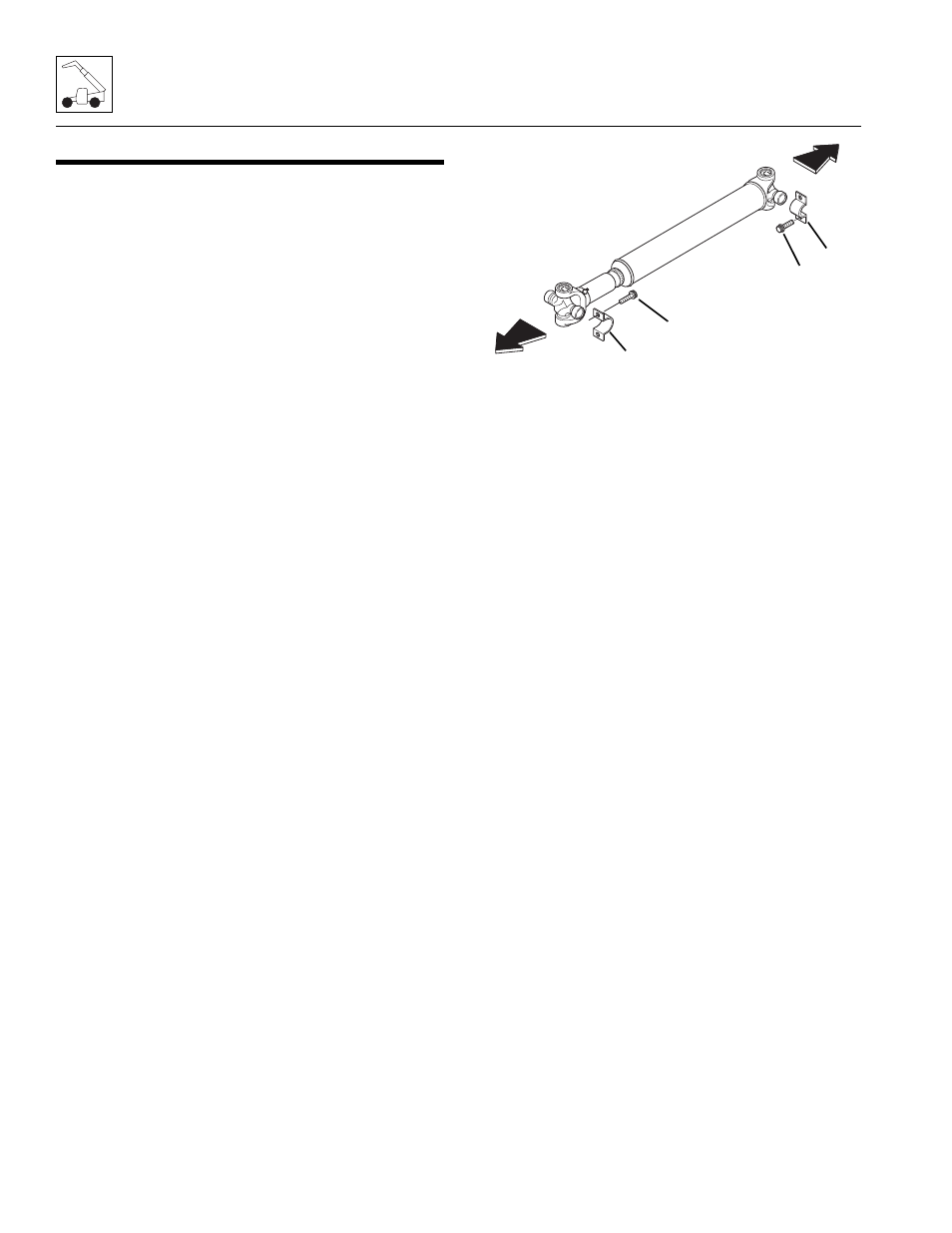

7. Remove the four bolts (1) and two straps (2)

securing the bearing cross to the transmission

output shaft flange.Discard the bolts.

8. Remove the four bolts (3) and two straps (4)

securing the bearing crosses to the axle.

9. Remove the drive shaft assembly.

10. Repeat the above procedure on the rear drive shaft.

5.10.4

Drive Shaft Cleaning and Drying

1. Disassemble and clean all parts using an approved

cleaning fluid. Allow to dry.

2. Remove any burrs or rough spots from all machined

surfaces. Re-clean and dry as required.

5.10.5

Drive Shaft Installation

1. Raise the drive shaft assembly into position. The slip

yoke end of the drive shaft mounts toward the axle. If

reinstalling a drive shaft previously removed, align

the flange yokes according to the alignment marks

made during removal.

Note: Yokes at both ends of the drive shaft must be in

the same plane to help prevent excessive vibration.

2. Apply Loctite

®

243

TM

to all mounting bolts.

3. Install the two straps (2) and four new bolts (1)

securing the bearing crosses to the transmission.

Torque capscrews to 38 Nm (lb-ft).

4. Install the two straps (4) and four new bolts (3)

securing the bearing crosses to the axle. Torque

capscrews to 38 Nm (lb-ft).

5. Repeat the above procedure on the rear drive shaft.

6. Properly connect the battery.

7. Close and secure the engine cover.

8. Unblock the wheels.

9. Remove the Do Not Operate Tag from the ignition

key switch and the steering wheel.

MT0350

TO AXLE

TO TRANSMISSION

1

4

2

3