IAI America SSPDACR User Manual

Page 79

13. Replacement/Adjustment Procedure for Stainless Sheet

71

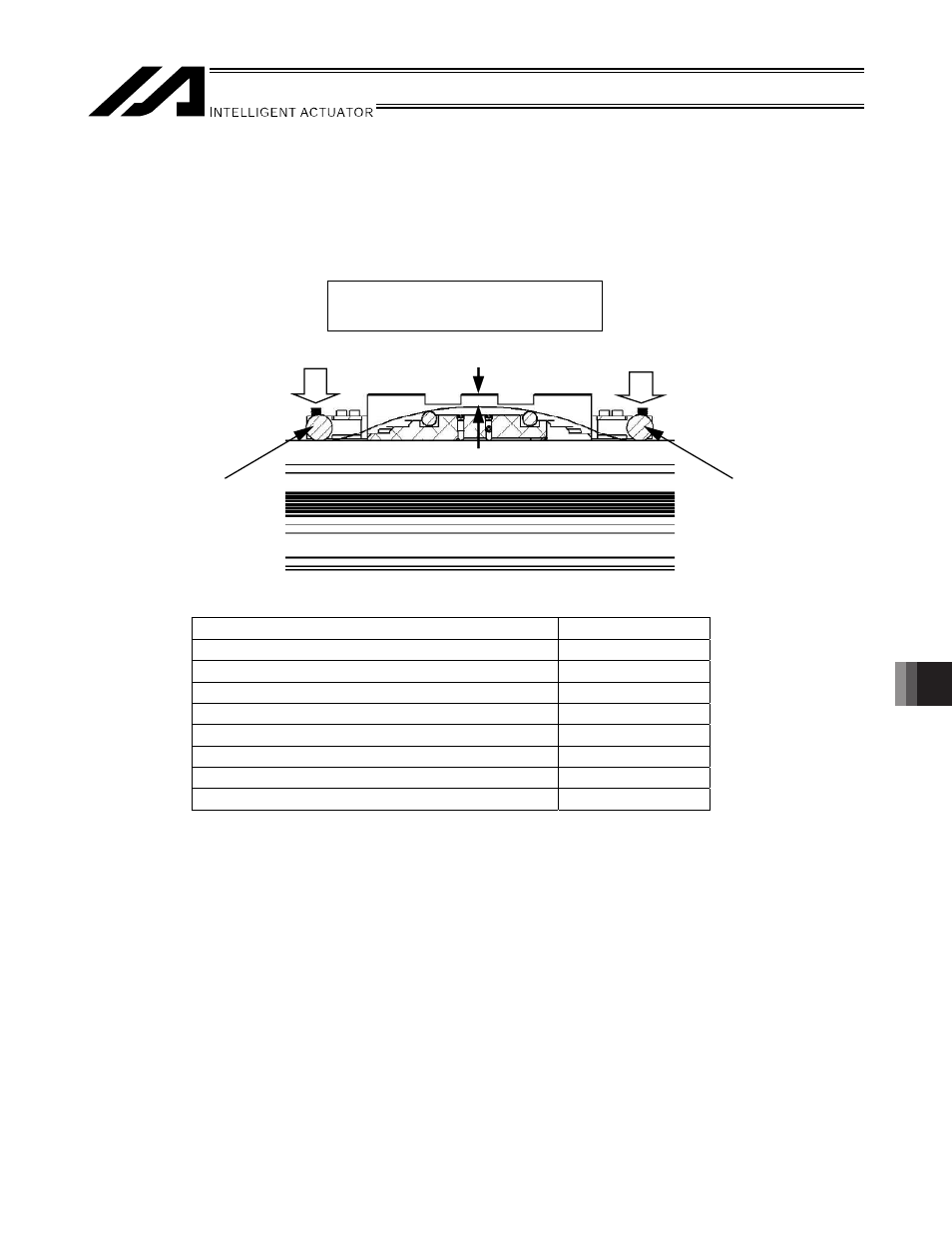

(6) Adjust the tension of the stainless sheet.

[1] Move the stainless sheet back and forth to adjust the sheet tension. If the actuator is of clean room type,

push down the rollers until they contact the side cover. This is not necessary with a standard actuator

because there are no rollers.

[2] Adjust the sheet tension until the distance between the apex of the sheet and top face of the slider meets

the applicable distance shown in the table below, and then loosely tighten the screws on the front side

you have loosened earlier, just enough to keep the stainless sheet from moving.

Distance between apex of stainless sheet and top face of slider

Type

H [mm]

ISDB-S, ISPDB-S, ISDBCR-S, ISPDBCR-S

6

ISDB-M, ISPDB-M, ISPDBCR-M, ISDBCR-M

6.5

ISDBCR-MX, ISPDBCR-MX

5.5

ISDB-L/LX, ISPDB-L/LX, ISDBCR-L, ISPDBCR-L

9

ISDBCR-LX, ISPDBCR-LX

8

SSPDACR-S

7

SSPDACR-M

8

SSPDACR-L

9

(7) Move the slider several times over the entire stroke to check the tension by checking if the stainless sheet

contacts the slider.

If the lead is small or the actuator is a vertical axis, the slider cannot be moved by hand. In this case, turn on

the controller power and move the slider at a speed of approx. 20 mm/s using the teaching pendant or PC

software.

Distance from top face of slider to

apex of stainless sheet (H)

Push down with a force

of approx. 5 N (0.5 kgf).

Push down with a force

of approx. 5 N (0.5 kgf).

Roller

Roller