9 isdbcr, ispdbcr-l, Appendix 98 – IAI America SSPDACR User Manual

Page 106

15.

Appendix

98

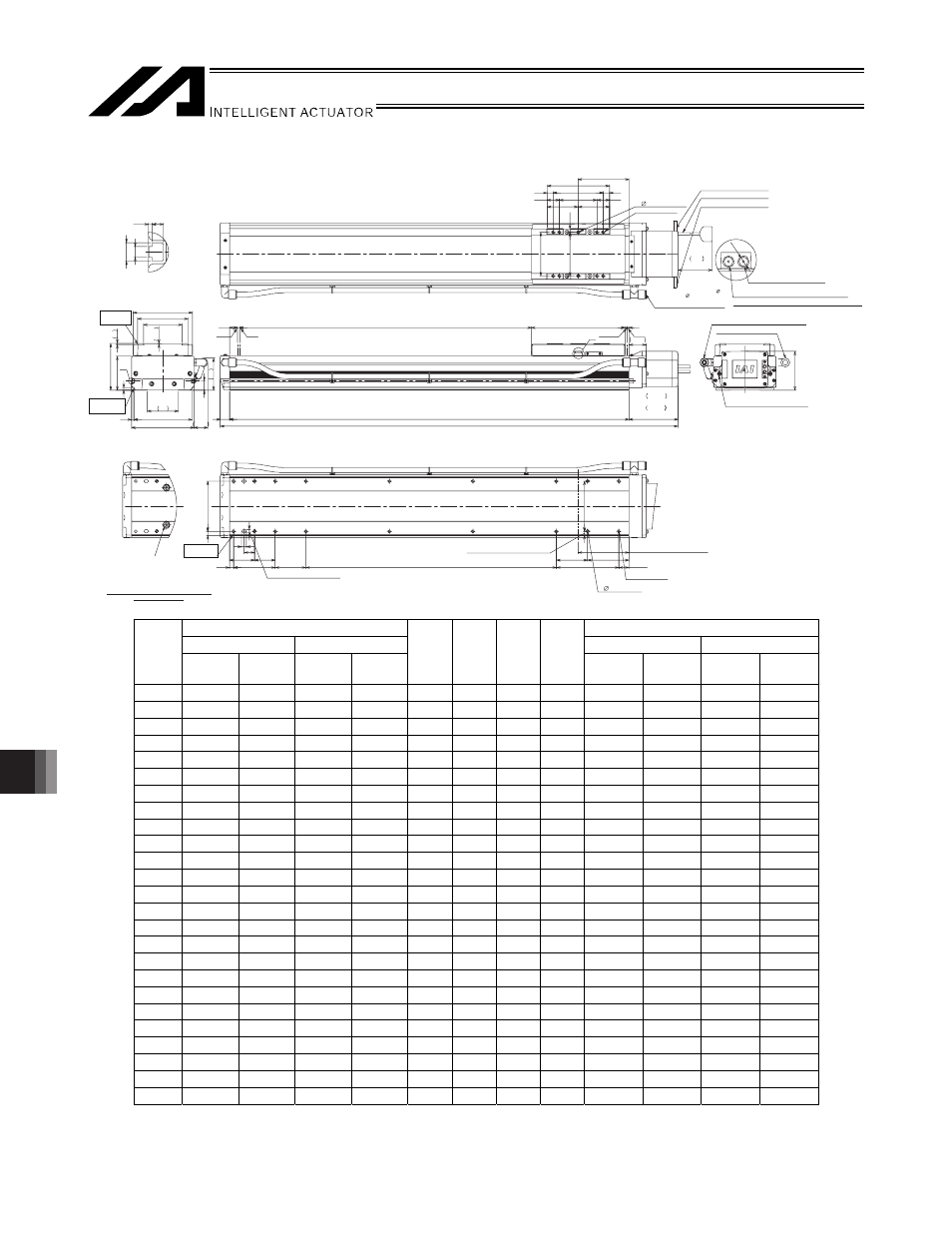

15.1.9

ISDBCR, ISPDBCR-L

L

Weight [kg]

200 W motor

400 W motor

200 W motor

400 W motor

Stroke

Without

brake

With

brake

Without

brake

With

brake

B

D

E

F

Without

brake

With

brake

Without

brake

With

brake

100

497

531

519

553

358

0

8

73.5

11.9

12.4

12.3

12.8

150

547

581

569

603

408

0

8

123.5

12.7

13.2

13.1

13.6

200

597

631

619

653

458

0

8

173.5

13.6

14.1

14.0

14.5

250

647

681

669

703

508

1

10

23.5

14.4

14.9

14.8

15.3

300

697

731

719

753

558

1

10

73.5

15.3

15.8

15.7

16.2

350

747

781

769

803

608

1

10

123.5

16.2

16.7

16.6

17.1

400

797

831

819

853

658

1

10

173.5

17.0

17.5

17.4

17.9

450

847

881

869

903

708

2

12

23.5

17.9

18.4

18.3

18.8

500

897

931

919

953

758

2

12

73.5

18.7

19.2

19.1

19.6

550

947

981

969

1003

808

2

12

123.5

19.6

20.1

20.0

20.5

600

997

1031

1019

1053

858

2

12

173.5

20.4

20.9

20.8

21.3

650

1047

1081

1069

1103

908

3

14

23.5

21.3

21.8

21.7

22.2

700

1097

1131

1119

1153

958

3

14

73.5

22.1

22.6

22.5

23.0

750

1147

1181

1169

1203

1008

3

14

123.5

23.0

23.5

23.4

23.9

800

1197

1231

1219

1253

1058

3

14

173.5

23.9

24.4

24.3

24.8

850

1247

1281

1269

1303

1108

4

16

23.5

24.7

25.2

25.1

25.6

900

1297

1331

1319

1353

1158

4

16

73.5

25.6

26.1

26.0

26.5

950

1347

1381

1369

1403

1208

4

16

123.5

26.4

26.9

26.8

27.3

1000

1397

1431

1419

1453

1258

4

16

173.5

27.3

27.8

27.7

28.2

1050

1447

1481

1469

1503

1308

5

18

23.5

28.1

28.6

28.5

29.0

1100

1497

1531

1519

1553

1358

5

18

73.5

29.0

29.5

29.4

29.9

1150

1547

1581

1569

1603

1408

5

18

123.5

29.8

30.3

30.2

30.7

1200

1597

1631

1619

1653

1458

5

18

173.5

30.7

31.2

31.1

31.6

1250

1647

1681

1669

1703

1508

6

20

23.5

31.5

32.0

31.9

32.4

1300

1697

1731

1719

1753

1558

6

20

73.5

32.4

32.9

32.8

33.3

A

B

21

1

93

143

3

6

140

121

5

150

32.5

77

5.

18

74

22

5.

1

5

19

5

5

Stroke

117 200W

139 400W

B

224

22

L

40.5

M.E.

S.E.

M.E.

HOME

300

50

1

20.

0±

150

120

90

15

15

30

30

8

50

1

75

75

122

122

150

D×200

100

24.5

99.5

F

02

1

20.

0±

75

01

10

60

50

02

1

25

12

8 H7

0

+0.015

39

3.

4

3.

7

1.5

4.5

6

Ø

Detail View A

2- 8 H7, depth 10

Reference

surface

4-M8, depth 18

10 (from the reference surface)

2-oblong , depth 10

Cable exit direction: Right

Grease nipple for ball screw

Screw for grounding wire

connection (M4 x 2 locations)

Reference

surface

4- 8, H7 depth 10

E-M8 depth 20

Slider center position (home)

Cable exit direction: Left

Cable length

Reference

surface

Grease nipple for guide (for supplying oil to the

guide on the installation surface side)

B (Same on the opposite side of grease nipples)

Cable exit direction: Rear

Air tube joint

Applicable tube outer diameter: 12

(Inner diameter: 5)

(Plug with plug screw Rc 3/8 on the

opposite side)

151 (200W BK type)

173 (400W BK type)

Joint installation position: Standard

Joint installation position: Opposite side

Base installation surface for

high-precision

guide specification

Machining jig holes are

provided across the bottom

surface of the base.

These holes are not used to

install the actuator.

Plug with rubber grommets.