5 isdb, ispdb-lx, Appendix 94 – IAI America SSPDACR User Manual

Page 102

15.

Appendix

94

15.1.5

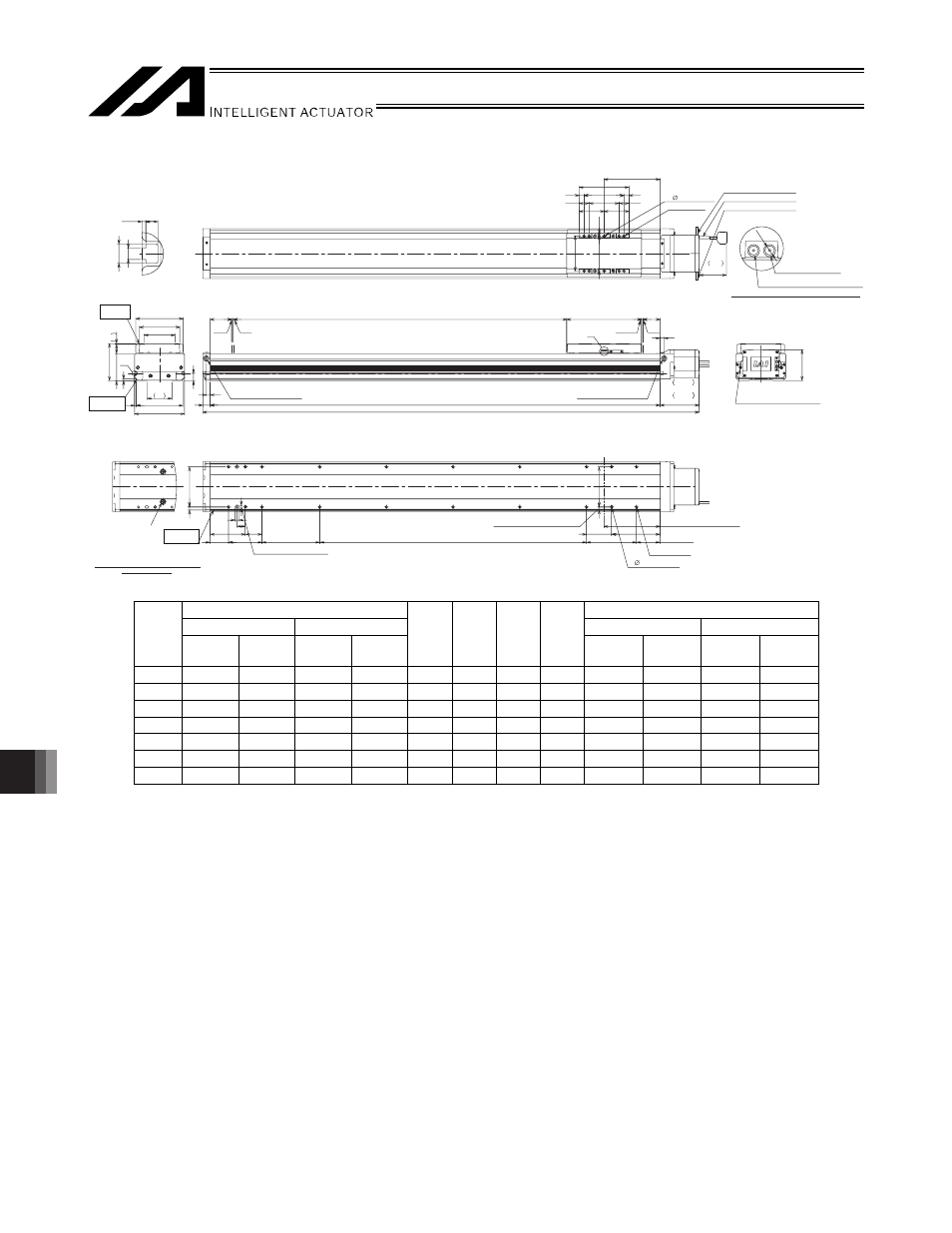

ISDB, ISPDB-LX

L

Weight [kg]

200 W motor

400 W motor

200 W motor

400 W motor

Stroke

Without

brake

With

brake

Without

brake

With

brake

B

D

E

F

Without

brake

With

brake

Without

brake

With

brake

1000

1489

1523

1511

1545

1350

4

16

173.5

29.7

30.2

30.1

30.6

1100

1589

1623

1611

1645

1450

5

18

73.5

31.4

31.9

31.8

32.3

1200

1689

1723

1711

1745

1550

5

18

173.5

33.2

33.7

33.6

34.1

1300

1789

1823

1811

1845

1650

6

20

73.5

35.0

35.5

35.4

35.9

1400

1889

1923

1911

1945

1750

6

20

173.5

36.7

37.2

37.1

37.6

1500

1989

2023

2011

2045

1850

7

22

73.5

38.5

39.0

38.9

39.4

1600

2089

2123

2111

2145

1950

7

22

173.5

40.2

40.7

40.6

41.1

A

B

21

1

6

140

5

150

5.

18

74

22

3

93

121

143

51

5

65

Stroke

5

117 200W

139 400W

B

22

L

12

224

11

M.E.

S.E.

M.E.

HOME

300

8

50

1

20.

0±

50

1

75

75

90

30

30

120

15

15

150

168

168

150

D×200

100

70.5

145.5

F

02

1

20.

0±

75

01

56

106

50

02

1

25

12

8 H7

0

+0.015

39

3.

4

3.

7

1.5

4.5

6

Ø

Detail View A

2- 8 H7, depth 10

Reference

surface

8-M8, depth 20

10 (from the reference surface)

2-oblong , depth 10

Cable exit direction: Right

Grease nipple for ball screw

Screw for grounding wire

connection (M3 x 2 locations)

Tapered tube screw (Rc 3/8)

(Plug with plug screw; same

on the opposite side)

Reference

surface

4- 8, H7 depth 10

E-M8 depth 20

Slider center position (home)

Cable exit direction: Left

Cable length

Reference

surface

Grease nipple for guide (for supplying oil to

the guide on the installation surface side)

B (Same on the opposite side of grease nipples)

Tapered tube screw (Rc 3/8)

(Plug with plug screw; same

on the opposite side)

Cable exit direction: Rear

151 (200W BK type)

173 (400W BK type)

Base installation surface for

high-precision

guide specification

Machining jig holes are

provided across the bottom

surface of the base.

These holes are not used to

install the actuator.

Plug with rubber grommets.