IAI America SSPDACR User Manual

Page 43

6. Installation

35

6.2.2

Preciseness of the Installation Surface

x

The frame on which the actuator is installed shall have sufficient structural rigidity to remain free from

vibration, etc.

x

The basis of measurement of the running accuracy of the slider is from the lower side and motor side to

right side.

If accuracy for its run is required, use these surfaces as a datum of the installation.

In view of the motor side, the parallelism of the quasi-reference surface of left side to the reference surface

is 0.1mm or less.

x

The actuator installation surface shall be a flat surface that has been machined or has equivalent precision,

where the specific flatness of the installation surface shall be within 0.05 mm. If the installation surface is

rough, abnormal noise or other problems may occur due to poor contact of the actuator.

x

If the actuator is of straightness high-precision specification (indicated by the option model number “ST”),

clean the base surface of any soiling and install the actuator on a flat surface with a preciseness of

0.02 mm in flatness.

[For the straightness high-precision specification (indicated by the option model number “ST”), refer to 10.9,

“High-Precision Straightness Specification.”]

x

Provide enough space needed to carry out maintenance work.

z

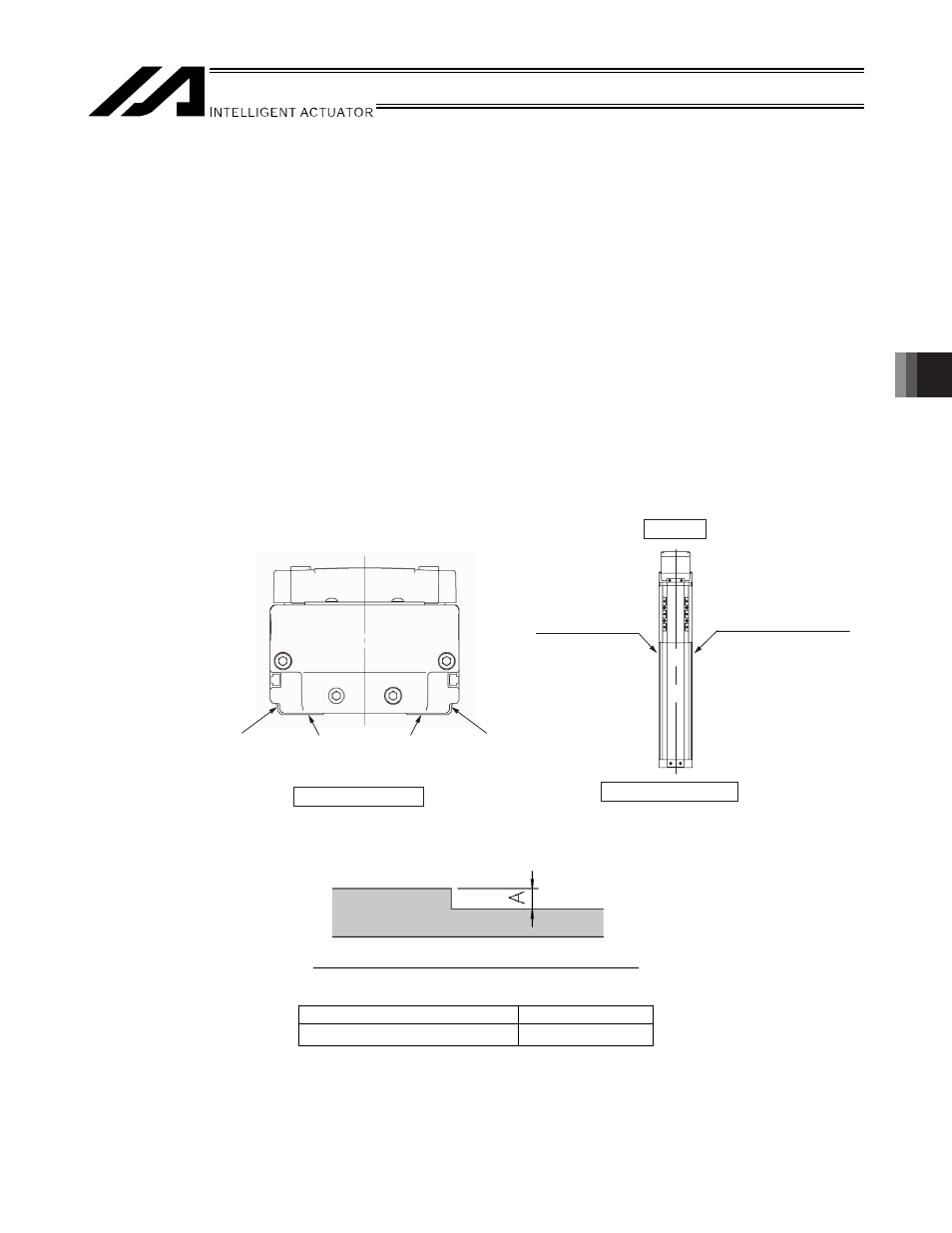

ISDB, ISPDB, ISDBCR, ISDBCR

Base reference surface (side)

Base reference surface (bottom)

Quasi-reference surface

View from the front side

Motor side

View from the upper side

Quasi-reference surface

Reference surface

x

If the reference surface (side) of the base is used, provide a stopper part of the dimension shown below.

Dimension of stopper part on reference surface

Type

Dimension A

Base reference surface (side)

3 to 5