3 installing the load on the slider – IAI America SSPDACR User Manual

Page 45

6. Installation

37

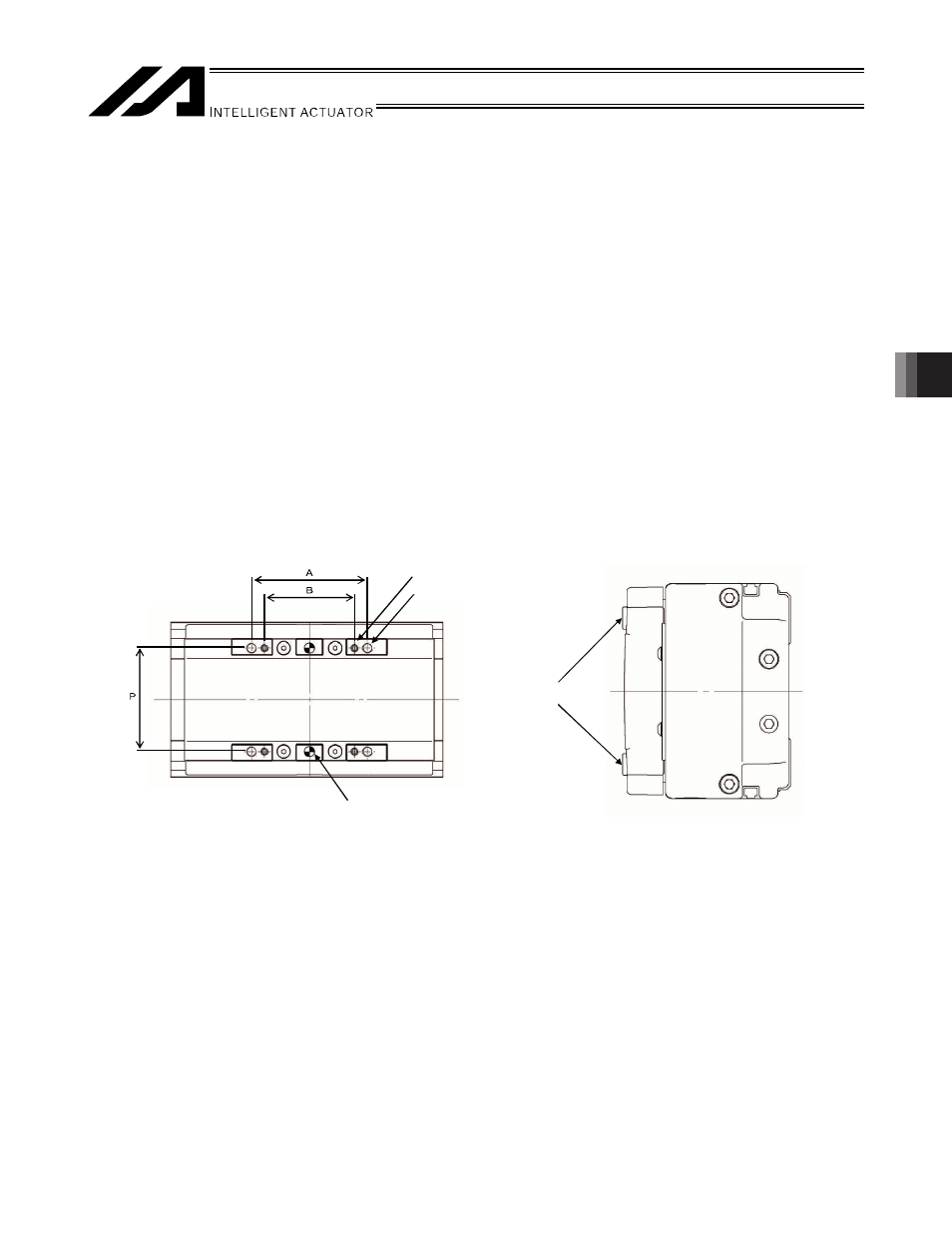

6.3 Installing the Load on the Slider

x

The slider has two types of threaded holes, so affix the load using these holes. The affixing method shall

conform to the method for installing the actuator.

x

Similarly when the slider is affixed and actuator is moved, install the slider using these threaded holes on

the slider.

x

The slider has two reamed holes. If repeatability is required after removal/re-installation, use positioning

pins. If squareness is required, use one positioning pin and make installation adjustment.

x

After removal/re-installation, repeatability can also be ensured by pushing the reference surface on the side

of the base.

x

Use high-tension bolts conforming to ISO 10.9 or higher.

x

When the threaded holes are used, determine the required thread length as specified below:

x

ISDB, ISPDB, ISDBCR, ISPDBCR

Depth of threaded hole > Thread engagement length > Nominal thread size x 1.8

x

SSPDACR

Depth of threaded hole > Thread engagement length > Nominal thread size

z

ISDB, ISPDB, ISDBCR, ISPDBCR

C

Slider reference surface

(top)

Thread B

Thread A

Reamed hole C