3 isdb, ispdb-mx, Appendix 92 – IAI America SSPDACR User Manual

Page 100

15.

Appendix

92

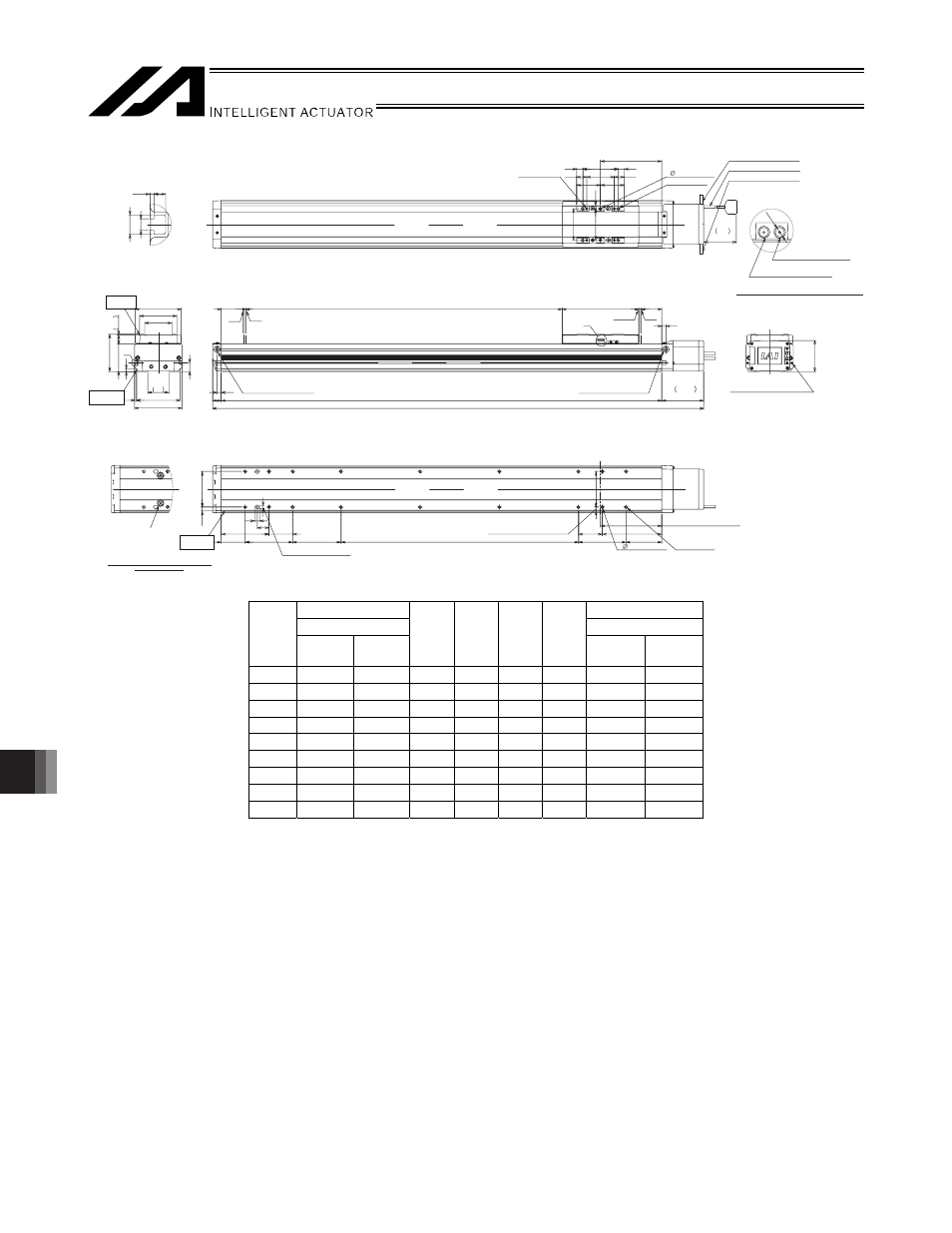

5.1.3

ISDB, ISPDB-MX

L

Weight [kg]

200 W motor

200 W motor

Stroke

Without

brake

With

brake

B

D

E

F

Without

brake

With

brake

800

1241

1276

1113

3

14

122

18.3

18.8

900

1341

1376

1213

3

14

222

19.6

20.1

1000

1441

1476

1313

4

16

122

20.9

21.4

1100

1541

1576

1413

4

16

222

22.2

22.7

1200

1641

1676

1513

5

18

122

23.4

23.9

1300

1741

1776

1613

5

18

222

24.7

25.2

1400

1841

1876

1713

6

20

122

26.0

26.5

1500

1941

1976

1813

6

20

222

27.3

27.8

1600

2041

2076

1913

7

22

122

28.6

29.1

49

6

110

5

120

5.

96

54

22

69

94

116

5.

2

5

56

5 53

Stroke

106 200W

L

B

22

11

194

10

M.E.

S.E.

M.E.

HOME

300

08

20.

0±

7

08

60

60

70

25

25

90

15

15

155

155

120

D×200

120

60.5

90.5

150.5

120.5

30

09

20.

0±

09

60

12

8 H7

0

+0.015

01

60

F

87

3.

4

3.

7

1.5

4.5

6

Ø

A

B

Detail View A

2- 8 H7, depth 10

Reference

surface

4-M8, depth 18

10 (from the reference surface)

2-oblong , depth 10

Cable exit direction: Right

Grease nipple for ball screw

Screw for grounding wire

connection (M3 x 2 locations)

Tapered tube screw (Rc 3/8)

(Plug with plug screw; same

on the opposite side)

Reference

surface

4- 8, H7 depth 10

E-M8 depth 20

Slider center position (home)

Cable exit direction: Left

Cable length

Reference

surface

Grease nipple for guide

(for supplying oil to the guide on

the installation surface side)

B (Same on the opposite side of grease nipples)

Tapered tube screw (Rc 3/8)

(Plug with plug screw; same

on the opposite side)

Cable exit direction: Rear

141 (200W BK type)

Base installation surface for

high-precision

guide specification

Machining jig holes are

provided across the bottom

surface of the base.

These holes are not used to

install the actuator.

Plug with rubber grommets.

4-M6, depth 18