Dc (high resistance) material – Atec Agilent-16047A User Manual

Page 82

77

DC (High resistance)

Material

Furnished Accessories:

Options:

16008B-001:

Add 26 & 76 mm diameter electrodes

16008B-002:

Add 26 mm diameter electrode

Compensation and Measurement: Using the selector

switch on the 16008B, select either the volume resistivity

or surface resistivity measurement configuration. Open

compensation is recommended before measurement and

when the measurement configuration is switched.

Separate the upper electrode from the main electrode by

turning the contact pressure load knob until the upper

electrode does not move. Then, close the top cover and

perform open compensation. After open compensation, the

material under test (MUT) is placed on the main electrode

and the upper electrode is placed over it. Next, turn the

load knob to adjust the electrode contact pressure on the

MUT. Close the top cover and measure the MUT's surface

or volume resistivity.

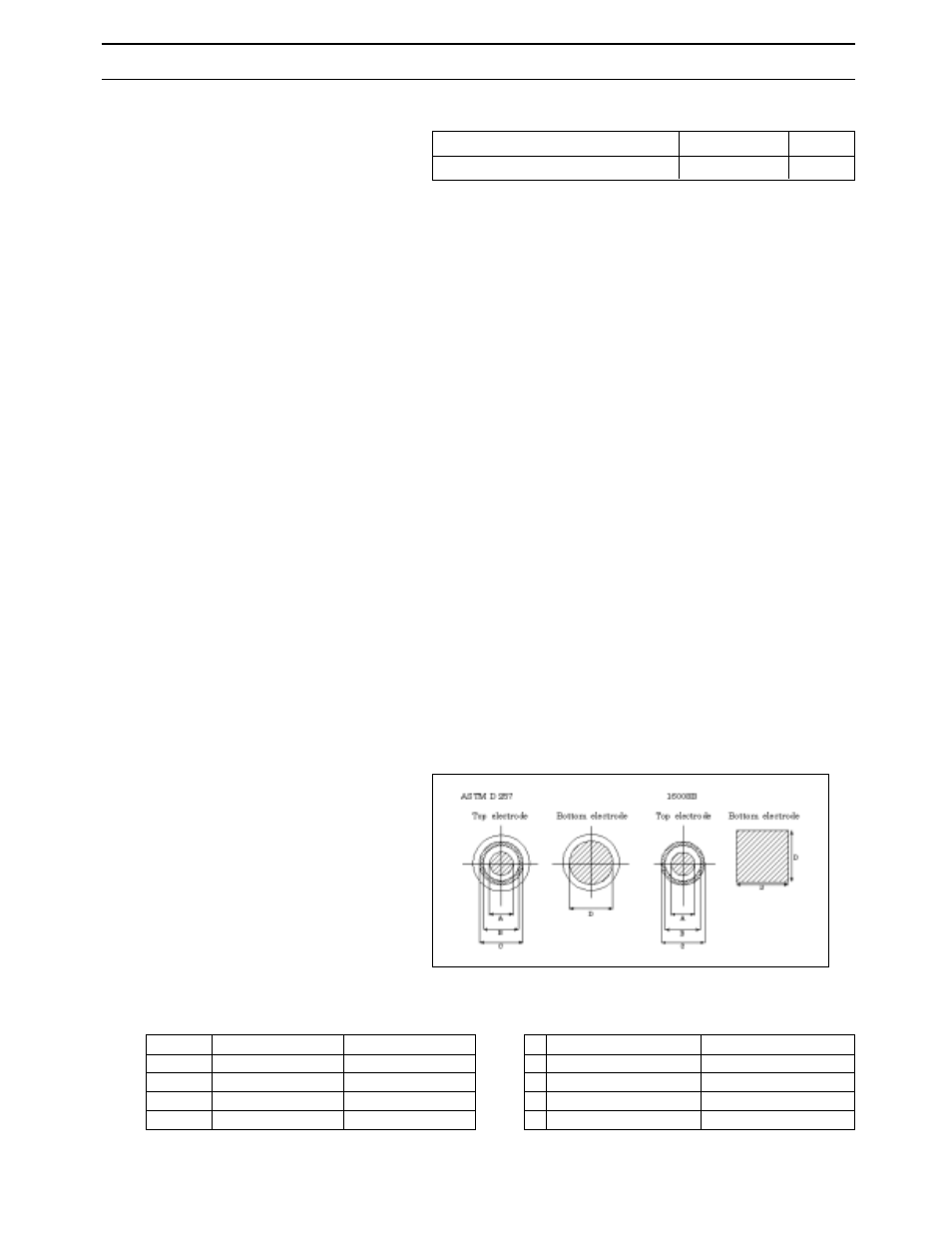

It is vital to make measurements, which are compatible to

a certified test method (standard). It is shown below that

the 16008B can make resistivity measurements which are

compatible with ASTM D257 Standard Test Methods for

DC Resistance or Conductance of Insulating Materials. In

the figure and tables shown below, the size and shape is

compared for two pairs of electrodes: one that is specified

in ASTM D257 and the one that is used with the 16008B

Resistivity Cell. The similarity implies that the 16008B is

compatible with ASTM D257.

Compatibility with ASTM D257

Choice 1

Choice 2

A

76 mm

25 mm

B

88 mm

38 mm

C

100 mm

50 mm

D

100 mm

50 mm

Opt. 16008B-001

Opt. 16008B-001/002

A

76 mm

26 mm

B

88 mm

38 mm

C

98 mm

48 mm

D

110 mm

110 mm

ASTM D257's recommended electrode sizes

16008B electrode sizes

Description

P/N

Qty.

Operation and Service Manual

16008-90011

1