Bell & Gossett 10 001 265R5 TechnoForce Pump Controller User Manual

Page 33

TECHNOFORCE Installation, Operation, and Maintenance

27

Installation

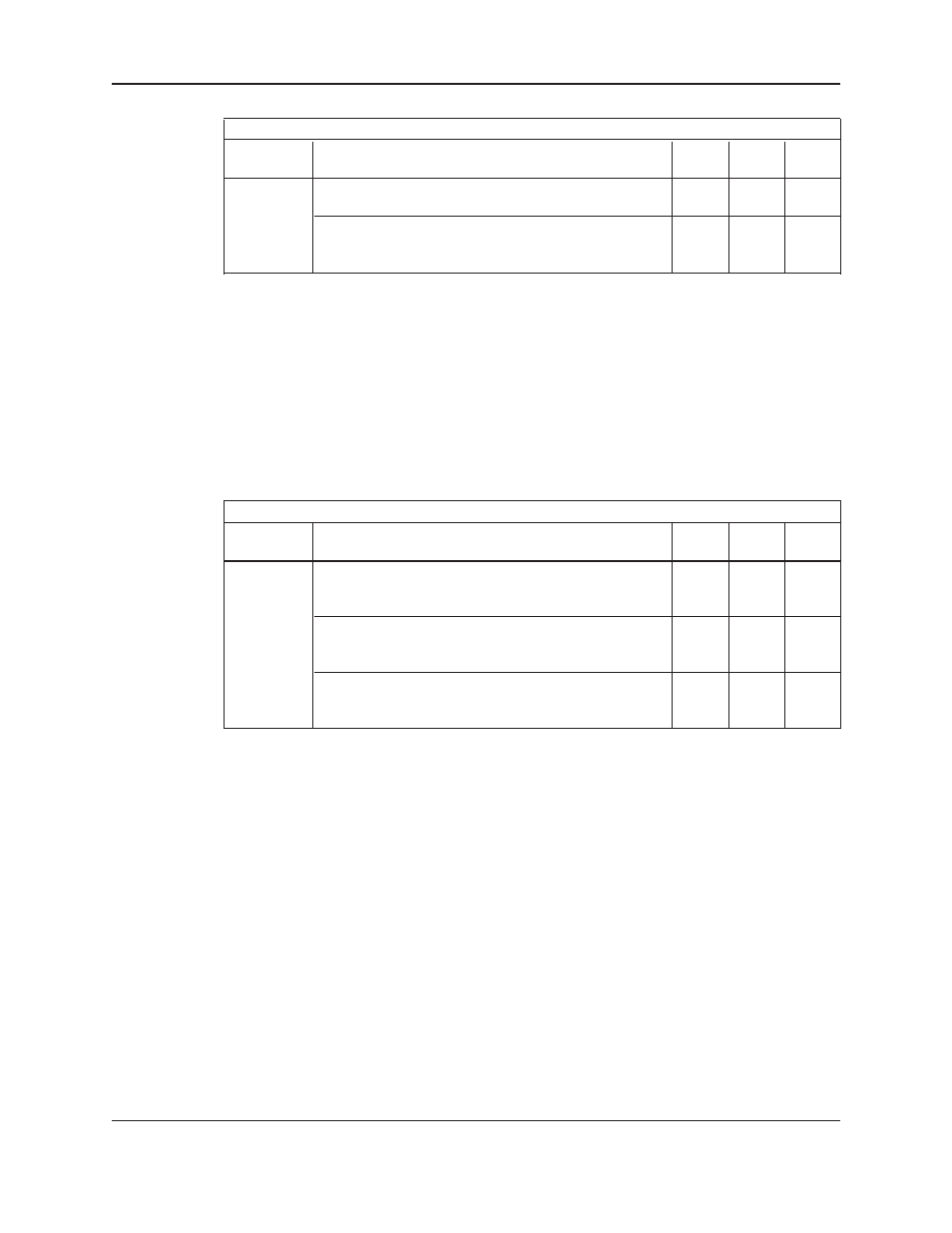

See following table for all

JC METASYS N2 menu items.

JC Metasys N2 Menu Items

Menu Item

Variable

Default Range Field

Value

JC Metasys

Node: ###

10

0-255

N2

The node number should be supplied by the BMS.

AI Ovrd = $

N

Y/N

Select “Y” to override analog inputs through the

communications port.

4.10.21 Modbus

The

MODBUS screen is displayed below:

Modbus

9600, 8, 1, 1, N RTU

Node: # Al Ovrd: $

OK: $(Y/N)

The first line confirms setup for Modbus protocol. The second line defines the 9600 bps baud rate, 8 bit data

pack, 1 stop bit, 1 start bits, and no parity. The third line requires user input. Obtain the node number from the

manufacturer that supplied the device that will communicate with the Controller.

See following table for all

MODBUS menu items.

Modbus Menu Items

Menu Item

Variable

Default Range Field

Value

Modbus

Baud: #####

9600

9600,

The baud rate is user adjustable parameter

19200,

38400

Node: ###

10

0-255

The node number should be supplied by the BMS

communications port.

AI Ovrd: $

N

Y/N

Select “Y” to override analog inputs through the

communications port.

4.10.22 Analog Input Override

If “Y” was entered for “AI Ovrd” in any of the communication setup screens above, the following screen will be

automatically displayed:

AI Override

AI1: $ AI2: $

AI3: $ AI4: $

OK $(Y/N)

Enter a “Y” next to each analog input type that will be overridden through the communications port.

4.10.23 Dynamic Flow Loss Compensation:

This energy savings feature allows user to compensate for the friction losses of system. As flow increases, the

pressure losses due to friction in the system will increase accordingly. This feature will allow controller to modify

the setpoint in real time based on the speed changes to compensate system friction loss. The controller will log

the last 40 real time setpoint changes. Figure 1 shows how this function works with setup parameters using an

example of a three pump system.