Fill tube weldment, Access port cover – Grain Systems PNEG-707GSI User Manual

Page 81

6. Tower Roof

PNEG-707 12', 18', 24' and 30' GSI Commercial Tower Dryer

81

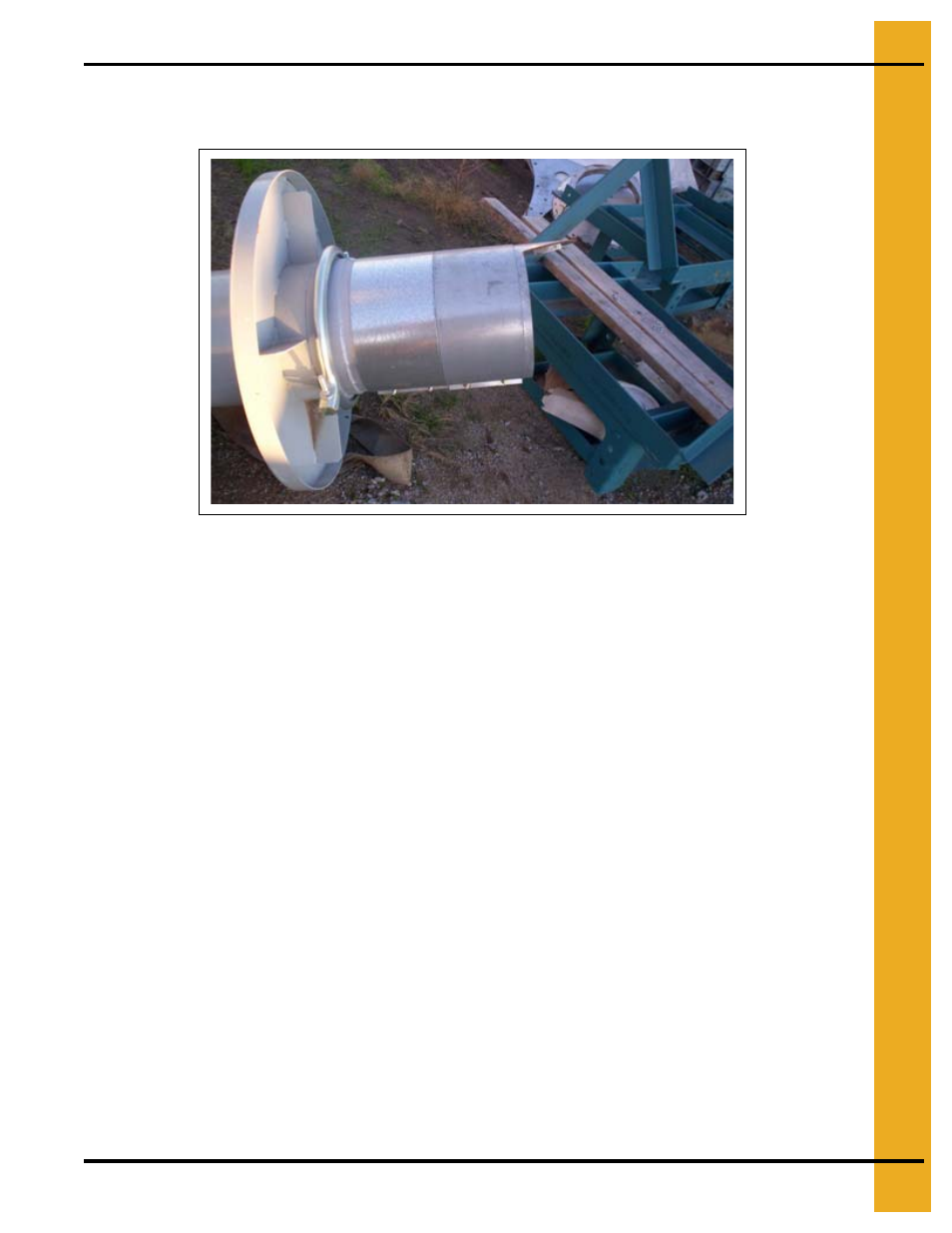

Fill Tube Weldment

Insert fill tube weldment into center collar.

Figure 6AG Fill Tube Weldment

Access Port Cover

Install access port cover to the tower roof sheet that has a cut out for the access port as follows.

1. Locate where moisture diverter will join access port tower roof sheet. Wipe area clean of oil and

press on strip caulking (24' rolls) to cover bolt holes.

2. With common bolts, bolt moisture diverter, then hinge base to access port tower roof sheet.

Use 5/16" x 3/4" stainless steel whiz lock bolts and nuts.

3. Use 3/8" x 1" stainless steel whiz lock bolts and nuts to bolt the following parts.

•

Hinge leaf to access port cover.

•

Hinge leaf to hinge base. Use double nut.

4. Place handle gasket under handle and bolt to access port cover.

Use two (2) 10-24 x 5/9" bolts and lock nuts.

NOTE: Insert handle shaft toward inside of dryer.

5. Bolt latch to shaft of handle as follows.

•

Insert 5/16" x 1-1/4", grade 5 bolt with nut and neoprene washer into latch.

•

Spin nut onto bolt.

•

Slide latch onto shaft of handle, up or down until it will catch bottom of tower roof sheet.

•

Tighten bolt to lock.

6. Bulb seal. Press pre-cut bulb seal onto rim of access port cut out on tower roof sheet.