High-limits (overheats), Installing conduit for high-limits – Grain Systems PNEG-707GSI User Manual

Page 103

8. Sensors

PNEG-707 12', 18', 24' and 30' GSI Commercial Tower Dryer

103

High-Limits (Overheats)

Install upper, middle and lower High-Limits on outside of dryer.

NOTE: See

for placement.

For sensors to work properly, it is important to install High-Limits on perforated sheets. Not on

horizontal seams.

Position junction boxes with drainage holes down and behind outside ladder screw in conduit. Secure

conduit close to junction box with 1/2" conduit hangers on existing bolts on seam.

Wrap copper tubing entirely around dryer. Clip with insulated clips.

Installing Copper Tubing

Install horizontal copper tubing as straight as possible and flush to dryer.

Secure copper tubing with insulated clips every 40". Insulated clips can be nutted down with second

stainless steel nut over existing nut.

Installing Conduit for High-Limits

•

Install one (1) 1/2", 10' IMC rigid, threaded conduit between each High-Limits. Continue conduit

down to approximately 10' above foundation.

•

Join conduit lengths with 1/2" conduit couplings.

•

Run conduit parallel or perpendicular to other conduits and dryer features.

•

Vertical conduit run should be plumb, neat, and orderly.

•

Conduit fittings must be dust-tight, raintight, and satisfy any hazard requirements for the site.

•

Seal all threads with pipe thread sealer to tighten seals and prevent leaks.

•

Use 1/2" conduit hangers every 80", and 5/16" whiz nuts.

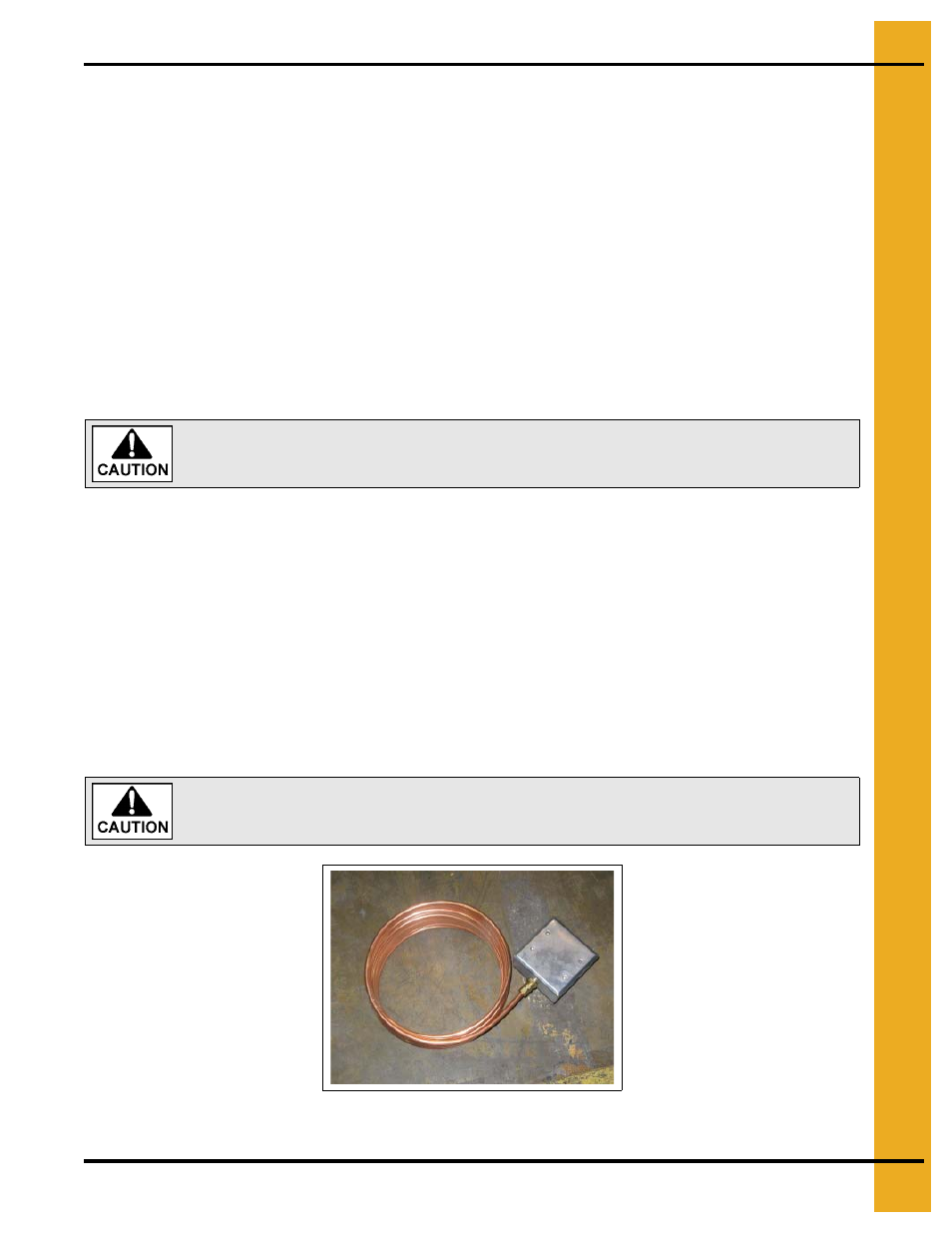

Figure 8N One (1) (outside) High-Limit consists of

one (1) junction box and two (2) copper tubings.

Do not kink or cut off end of gasfilled copper tubing.

Do not kink or cut off end of gasfilled copper tubing.