Burner and burner housing (continued) – Grain Systems PNEG-707GSI User Manual

Page 147

14. Burner and Reducer

PNEG-707 12', 18', 24' and 30' GSI Commercial Tower Dryer

147

Burner and Burner Housing (Continued)

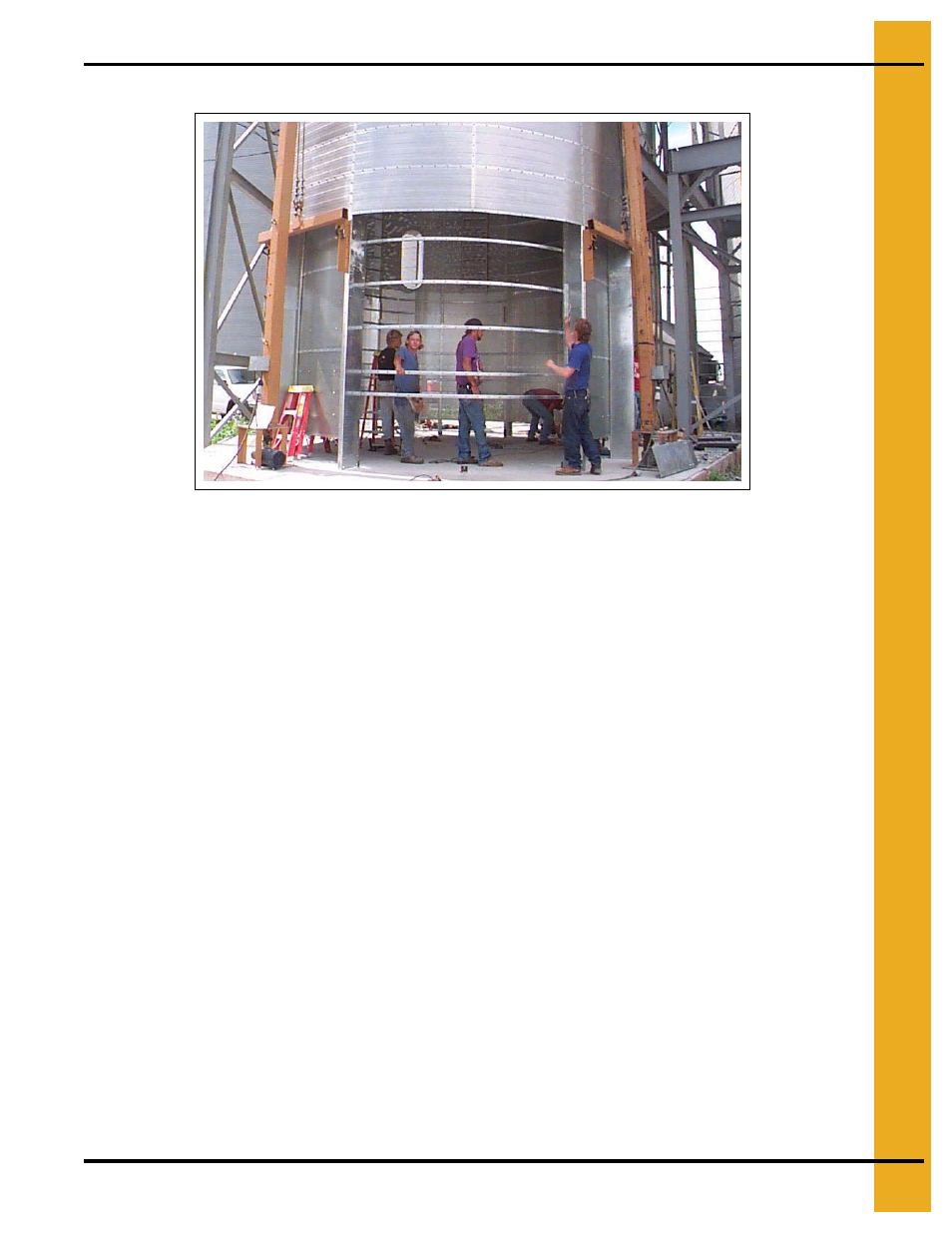

Figure 14G Install rolled plenum channels across gap to maintain shape and stability.

Remove rolled plenum channels when ready to move burner into dryer.

Depending on model,

, burner housing.

See Orientation Section on Page 32

for flat layout for heat section door frame placement.

See Windows and Doors on Page 187

for windows and doors for heat section door and reducer

door installation.

1. Remove rolled plenum channels and bring in both halves of burner housing. See illustration for

up/down orientation.

Also place burner, burner baffle, and other parts inside burner housing to avoid lifting them in later.

(Other parts are burner baffle supports, burner mounting brackets, burner support brackets, and

burner support tees).

2. Align and bolt halves of burner housing. Use 5/16" x 1" galvanized whiz lock bolts and nuts.

3. Overlap and bolt sections of burner housing outlet baffle to top ring of burner housing.

Use 5/16" x 1" galvanized whiz lock bolts and nuts.

4. Check orientation of burner pilot section (with installation points for ignitor and flame sensor).

Plan to install burner so pilot section wiring will make direct run (usually through motor window to

control box.)

5. Measure to determine correct bolt hole knock-outs for burner support parts. Knock out bolt holes

as required.

6. Install burner to burner housing as follows.

a. Loosely bolt four (4) burner mounting brackets to burner housing. Bracket them (orient as mirror

images). Use 3/8" x 1" galvanized bolts, nuts. Install washers on outside of burner housing.

b. Lift and temporarily support burner while installing burner support brackets below burner.

Loosely bolt two (2) burner support brackets to burner mounting brackets. Use 1/2" x 1-1/2"

galvanized bolts and nuts. Position burner over burner support brackets.