Grain Systems PNEG-707GSI User Manual

Page 75

6. Tower Roof

PNEG-707 12', 18', 24' and 30' GSI Commercial Tower Dryer

75

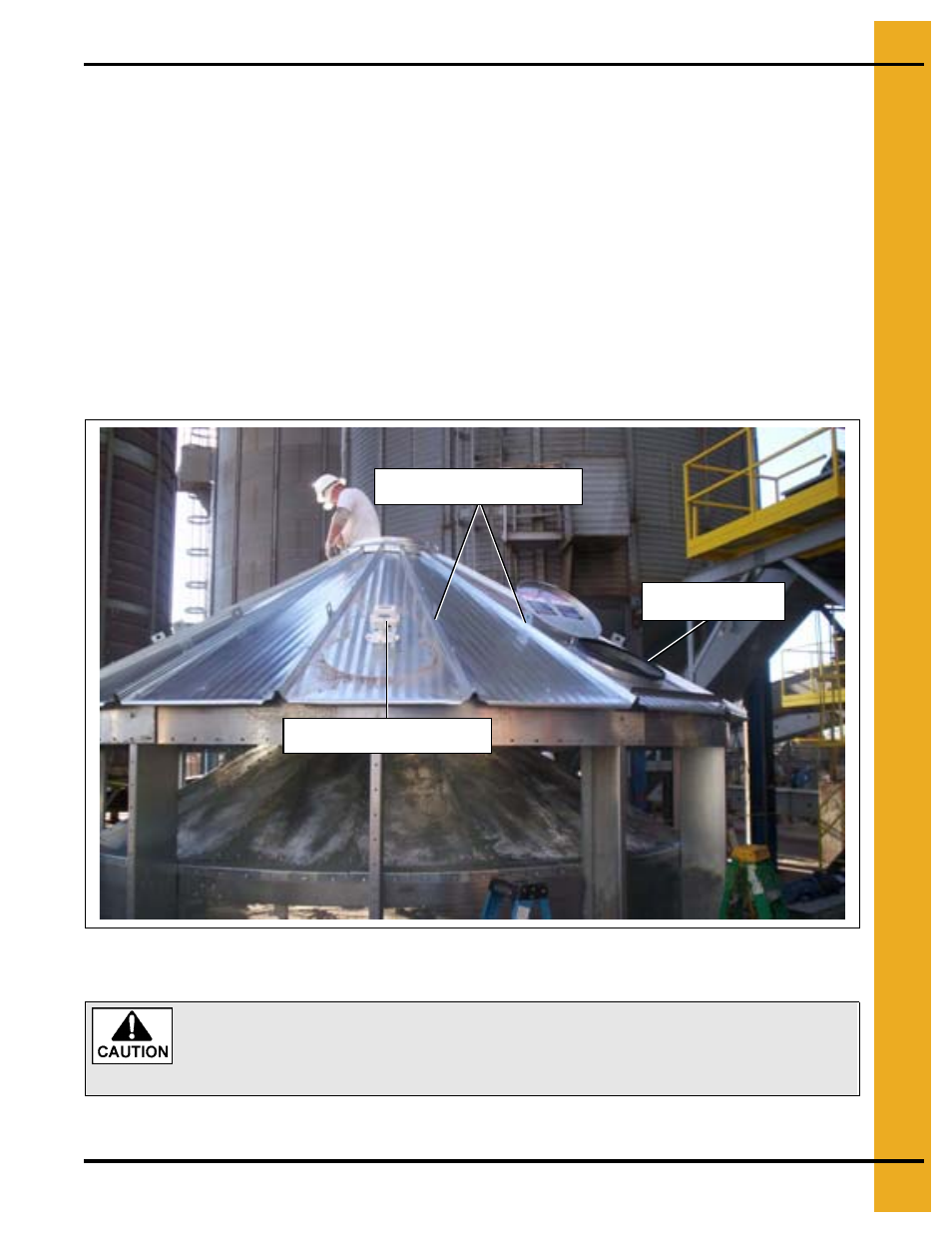

Tower Roof Sheets, Tower Roof Rungs and Expansion Ring Clips

NOTE: Install roof rungs and expansion ring clips to tower roof sheets during tower roof sheet installation.

Vertical Tower Roof Seams

Use 5/16" x 1-1/4" bin bolts, grade 5 bolts, 5/16" hex head nuts, and neoprene washers.

Leave out second to top bolt in tower roof vertical seams for center collar flashing installation.

Horizontal Tower Roof Seams

Use 5/16" x 3/4" bin bolts, grade 5 bolts, 5/16" hex head nuts, and neoprene washers.

All tower roof seams and add on parts:

Insert bolts toward inside of dryer, with neoprene washers against outside of dryer to provide seal.

Figure 6Q Install roof rungs on ribs of the tower

roof sheet with cut out for access port.

If there is an optional peak walk to install locate roof access point directly above roof hatch platform.

Tower roof sheet with

cut out for access port

Ribs of tower roof sheet are

where tower roof sheets overlap.

Upper bindicator (RA-6).

for installation.

Roof access port must be safely accessible from outside tower ladder.

Install tower roof sheet with cut out for roof access port directly above where

outside ladder will be installed. (If no peak walk used.)