Grain Systems PNEG-707GSI User Manual

Page 216

19. Tower Base

216

PNEG-707 12', 18', 24' and 30' GSI Commercial Tower Dryer

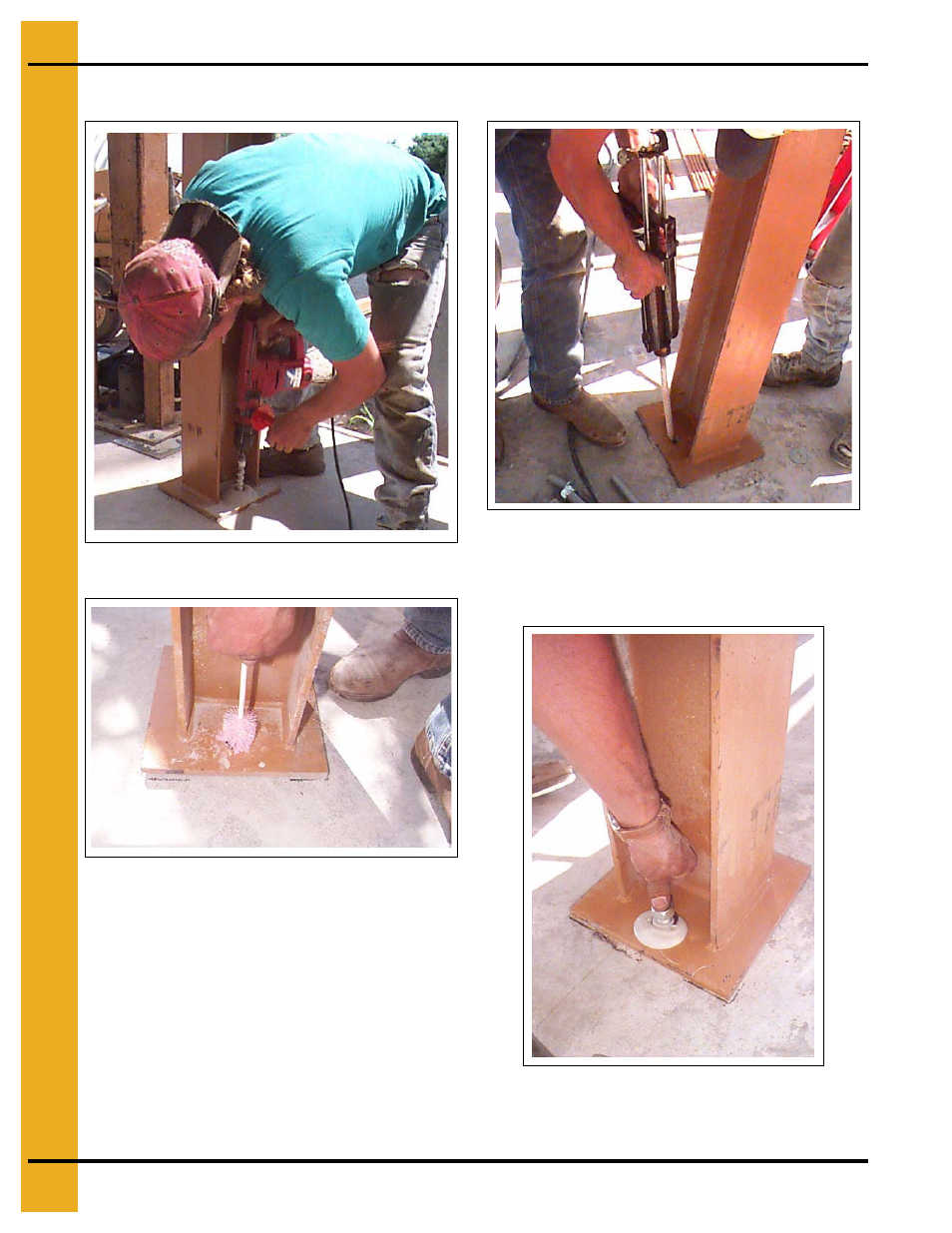

Follow Manufacturer’s Instructions to Apply Ceramic Epoxy

Figure 19AE Drill proper size hole.

Figure 19AF Clean Out Hole

Figure 19AG Fill hole with ceramic epoxy.

IMPORTANT: Thoroughly clean all debris

out of drilled hole for proper

epoxy adhesion.

Figure 19AH Insert HILTI HAS anchor bolt.

Move bolt up and down several times

to remove air pockets from epoxy.

See also other documents in the category Grain Systems Conditioners:

- PNEG-1890 (16 pages)

- PNEG-595 (26 pages)

- PNEG-1472 (30 pages)

- PNEG-897 (58 pages)

- PNEG-838 (4 pages)

- PNEG-1755 (36 pages)

- PNEG-524 (24 pages)

- PNEG-1080 (2 pages)

- PNEG-728 (47 pages)

- PNEG-673 (57 pages)

- PNEG-1717 (88 pages)

- PNEG-823 (42 pages)

- PNEG-630-6S (23 pages)

- PNEG-1876 (80 pages)

- PNEG-102 (2 pages)

- PNEG-366 (51 pages)

- PNEG-1626 (1 page)

- PNEG-1874 (78 pages)

- PNEG-1798 (34 pages)

- PNEG-1927 (4 pages)

- PNEG-924 (2 pages)

- PNEG-582 (26 pages)

- PNEG-012 (46 pages)

- PNEG-1797 (86 pages)

- PNEG-546 (26 pages)

- PNEG-951 (102 pages)

- PNEG-1650 (92 pages)

- PNEG-1649 (50 pages)

- PNEG-1376 (88 pages)

- PNEG-361 (46 pages)

- PNEG-338 (32 pages)

- PNEG-1276 (78 pages)

- PNEG-1283 (22 pages)

- PNEG-1089 (14 pages)

- QSG-001 (2 pages)

- PNEG-950 (96 pages)

- PNEG-1590 (3 pages)

- PNEG-501 (33 pages)

- PNEG-1447 (68 pages)

- PNEG-349 (32 pages)

- PNEG-236 (22 pages)

- PNEG-743 (16 pages)

- PNEG-900 (54 pages)

- PNEG-1935 (92 pages)