Grain Systems PNEG-707GSI User Manual

Page 222

21. Hopper

222

PNEG-707 12', 18', 24' and 30' GSI Commercial Tower Dryer

Hopper (Cross Section) Example - All Models (Continued)

See Orientation Section on Page 19

for orientation for dryer dimensions, components, wall sheet

guidelines, etc.

hardware, etc.

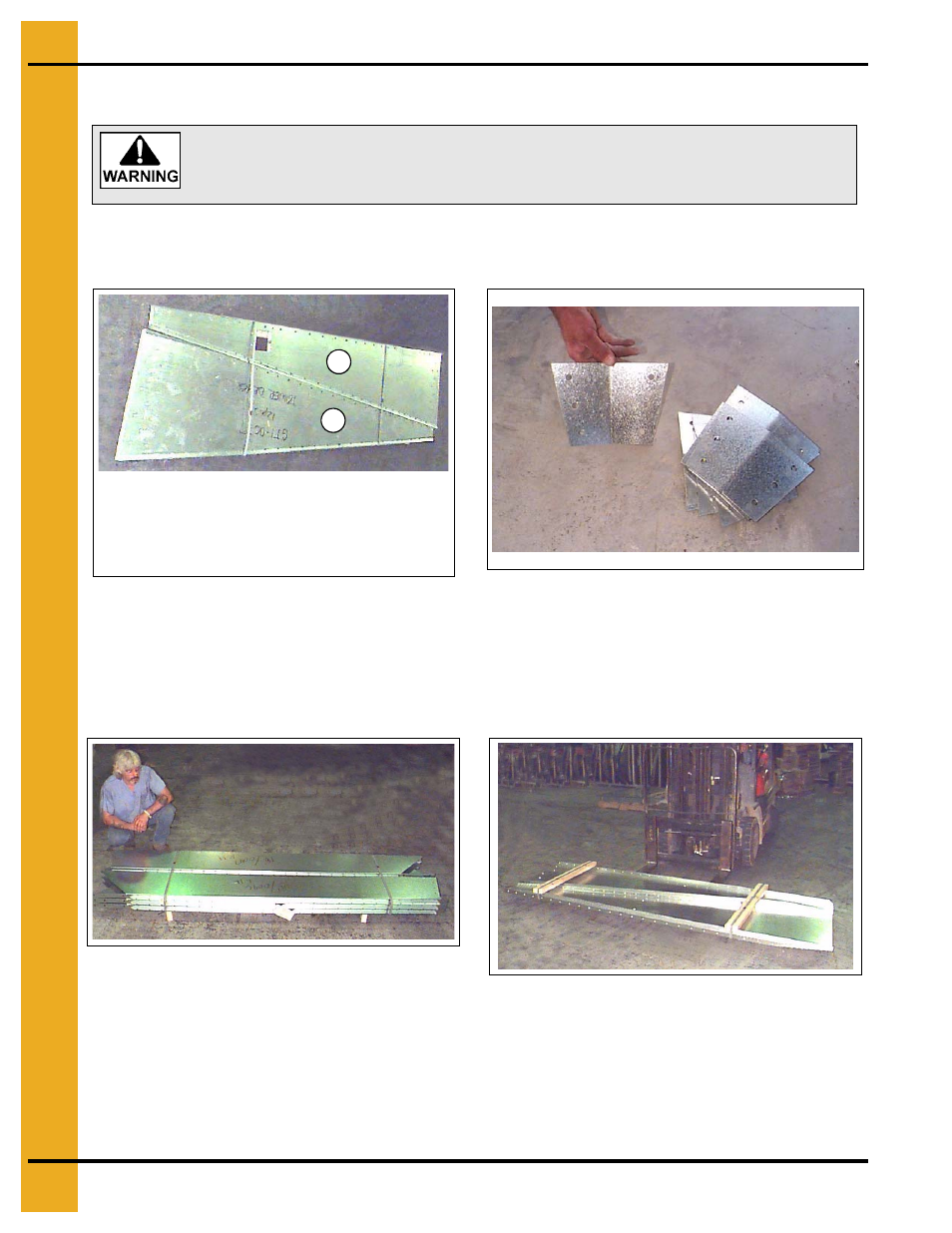

Figure 21B

Figure 21C Compression Angle Splices

1. Lapping outside hopper panels.

2. Lap outside hopper panel-R.H. with cut out on outside of dryer so slide gate will slide freely.

3. Outside hopper panels flat edges - Lap together and bolt.

4. Outside hopper panels angled edges - Lap together, then bolt under hopper channels with common bolts.

Figure 21D Hopper channels, R.H. and L.H. install

with diagonal-cut end down. Bottom side has

horizontal flange. Top side has vertical flange.

Figure 21E Inside Hopper Panels (under wood

shipping blocks).

Important Safety Precautions:

Dryer has sharp edges. These sharp edges may cause serious injury.

Use appropriate personal protective equipment. Use proper lifting techniques.

A

B

A. Outside hopper panel-R.H. with cut out for

slide gate (for emergency grain discharge).

B. Outside hopper panel-L.H.