Maintenance, 1 daily inspection – Omega RD200 User Manual

Page 123

-119-

21. MAINTENANCE

21.1 Daily Inspection

Check the residual quantity of chart paper, displaying/printing conditions, etc. on a daily basis in order to use your

recorder under good conditions.

1

Consumable parts check

Check items

Checking methods

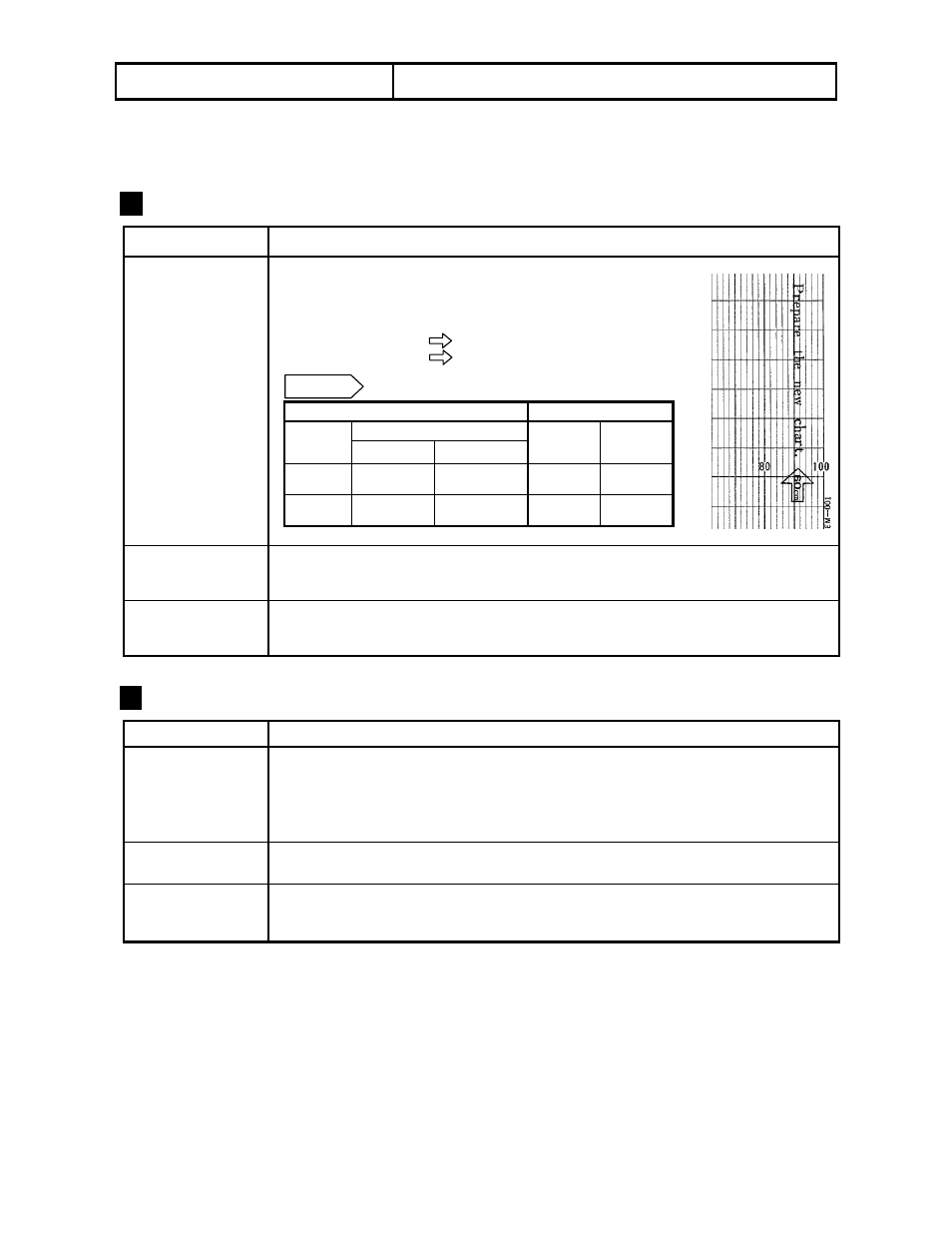

Check the residual quantity of chart.

When the residual quantity becomes less, a message “Prepare a

new chart” or “New Paper Required” appears with red ink on the

left of the chart paper.

• Loading chart paper See Section 5.1.

• Ordering chart paper See Section 1.2.

Continuous printing days of chart paper

RD200

RD2800

Continuous printing days

Chart

speed

Standard

16 m

Chart

speed

Continuous

printing

days

10 mm/h

Approx. 40

days

Approx. 60

days

25 mm/h

Approx. 30

days

20 mm/h

Approx. 20

days

Approx. 30

days

50 mm/h

Approx. 15

days

1. Residual quantity

of chart

2. Plotter pen

If the text on the digital data printing becomes unclear or pale, replace the plotter pen with

a new one. See Section 5.2.

3. Cartridge pen

If the line on the trace printing becomes unclear or pale, replace the cartridge pen with a

new one. See section 5.2.

2

Operation check

Check items

Checking details

1) Printing conditions

(1) Chart feeding condition

Check that there is no paper jam or dislocation from the sprocket.

(2) Text and trend line printing condition

Check that no disorder or abnormal condition is found in the text and trend line

printing.

2) Display conditions

Check that no abnormalities are found in the displays of measured values, status and bar-

graph.

3) Others

(1) Check that the measured values are normal.

(2) Check if any noise or strange odors are generated.

Reference