Mark-referenced positioning, 3 mark-referenced positioning, Application – Parker Products COMPAX-M /-S (L) User Manual

Page 229: Assignments, Wiring up the digital inputs and outputs, Compax, Function

Mark-referenced positioning

229

11.1.3 Mark-referenced positioning

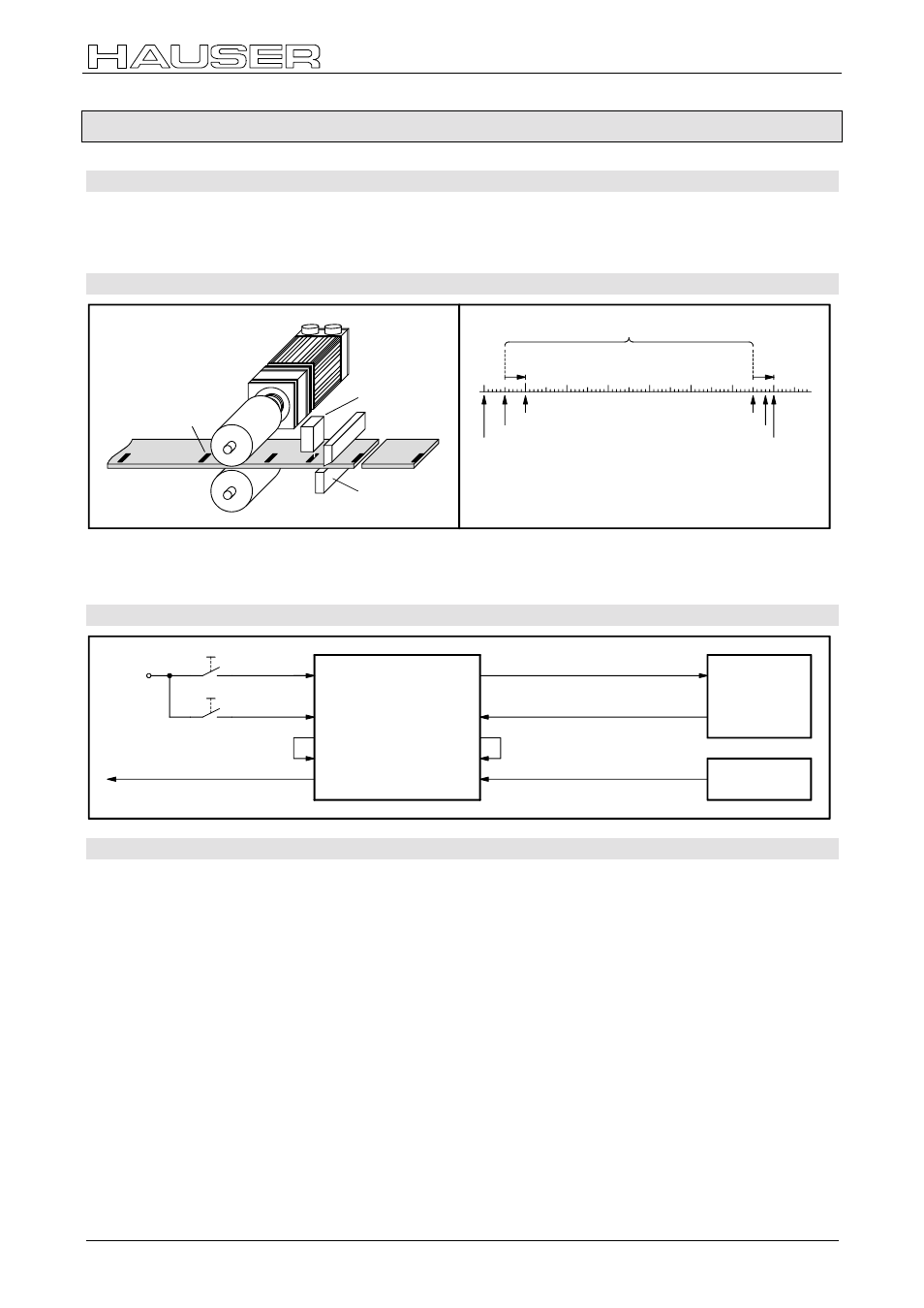

Application:

Pieces with lengths of between 100 mm and 500 mm should be cut from a plate roller. The cut-off positions

are specified by marks on the plate. If two marks are separated by more than 500 mm, the plate should be

pulled back to the last cut-off position.

Assignments:

label

light

barrier

shears

A

50mm

P38 = +650

P39 = +680

label window: range within which labels are detected

initial position

B

P37 = +50

P39

P38

P37: minimum distance to label.

: maximum distance to label.

: maximum feed if no label appears

within the window.

A :

POSR

50mm

POSR

position if label

appears at 50mm.

B : position if label

appears at 650mm.

The plate is fed by a roller feed controlled by COMPAX. A reflex light barrier detects the marks on the plate

and reports this to COMPAX. The distance between the light barrier and the shears is 50 mm. The shears

are controlled and monitored by COMPAX.

Wiring up the digital inputs and outputs:

I5

I6

+24V

start

stop

O7

I7

COMPAX

O15

massage

1 = label missing

0 = label detected

I15

O16

shears

0 = block

1 = activate

shears

0 = block

1 = open

O14

I14

I16

label input

0 = no label

1 = label

shears

light

barrier

Function:

The first event after COMPAX has been started is a rest of the control outputs. Once assurance has been

received that the blades of the shears are open, COMPAX is ready for the initial cutting to length.

The cutting to length process is triggered by a start pulse. COMPAX firstly activates the mark reference (I14)

using O14. After a waiting time of 10 ms (which is used to compensate for any possible COMPAX timing

offset), the mark-referenced positioning process is started using the "POSR 50 mm" command. The mark

input (I16) is approved after a travel distance of 50 mm (P37). If the light barrier now detects a mark,

COMPAX pushes the plate another 50 mm. This distance corresponds to the distance between the light

barrier and the shears and is programmed using "POSR 50 mm". If no mark has been detected after a travel

distance of 650 mm (P38), COMPAX stops the feed movement after a total of 680 mm (P39).

At the end of the positioning process, output O16 indicates whether a mark has been detected within the

mark window or not. This output is queried using I15.

If I15 is at 1 (i.e. mark found), COMPAX sets the message output O15 to 0 and activates the shears. Once

the blades have opened, COMPAX waits for the next start pulse. If I15 is 0 (i.e. no mark found), COMPAX

sets the message output O15 to 1, blocks the mark reference (I14) via O14, pulls the plate back by 680 mm

to the last cut-off position and waits for the next start pulse.