Interfaces, Error handling – Parker Products COMPAX-M /-S (L) User Manual

Page 171

Interfaces

Process coupling using HEDA (Option A1 / A4)

171

Unit

hardware

Connector

assignment / cable

Technical data

Configuration

Positioning and

control functions

Optimization

functions

Interfaces

Accessories /

options

Status

Parameter

Error list

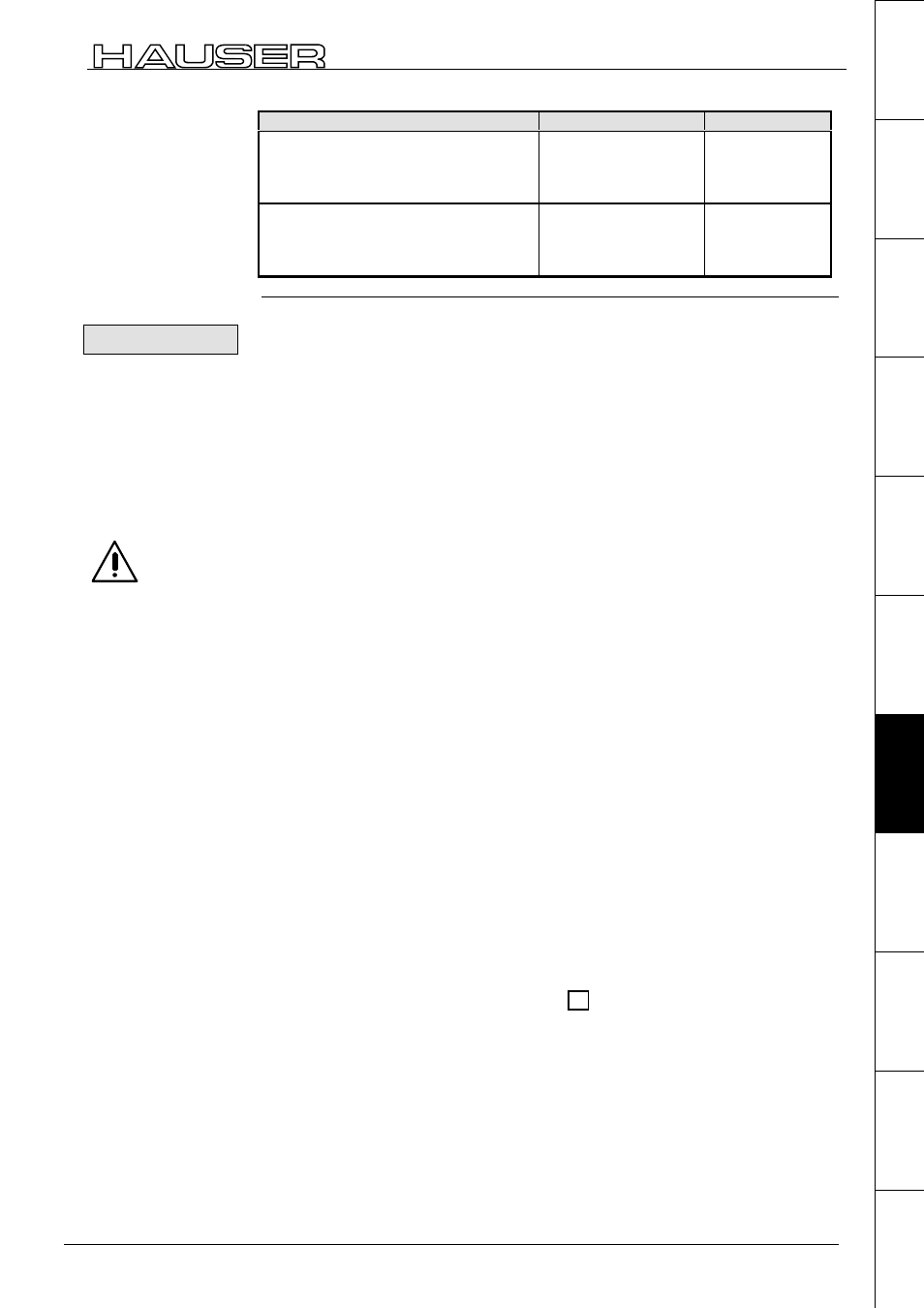

1st unit: Master

Slave

Coupling of several cams with the

same time base and separate master

or slave oriented label synchronization

(see above)

COMPAX XX70

P184=42 (time base)

P188=42

COMPAX XX70

P188=42

P143

s

=P143

M

Linking of several cams with the same

time base and absolute zero drift

between the axes due to the transfer of

a position value (see above)

COMPAX XX70

P184=43 (scaled

master position)

P188=43

COMPAX XX70

P188=43

P143

s

=P143

M

Only position signals can be completely restored following HEDA transmission

errors . When transmitting velocities, transmission errors can lead to drift

tendencies between the axis positions. For this reason use of the position

values is preferred.

HEDA transmission or synchronization errors are errors E76, E77 and E78.

Synchronization is interrupted with E76, therefore an alignment is implemented

whereby the process position value is aligned in such a manner that a position leap

does not occur.

With E77/E78, the slave attempts to reach the new undisturbed process position

value in order to maintain the reference system.

Transmitting "VC" interrupts the synchronization.

Only activate "VC" when the unit is switched off.

When working with the user terminal BDF2, "VC" is transmitted when the

"Parameter edit" menu is exited.

Position values / position (P184=40/43/44/45):

linear interpolation using old

values

Velocity values / frequencies (P184=42/46):

retains old value

In cases when P188>0 on the master side, a fixed delay in the associated process

value is implemented, amounting to a total of 2 ms. This ensures that the master

waits until all axes have received the process value. This ensures that all axes,

including the master, continue to process the new nominal values simultaneously.

♦

Except for fast start, no additional I/O's are sent.

♦

There can be only one master on the bus!

♦

The position values for P184=44 and P184=45 are derived independently of the

current positioning operating mode (normal, continuous, reset). They are

obtained from the nominal position value and the actual position value and

made available in 24-bit format, as if with counter channels. This avoids jerky

changes in the start torque (in continuous mode) or when reading the end of the

curve (in reset mode). Only the lower 24 bits of these values are transmitted,

consisting of the resolver value and maximum 256 motor revolutions.

The required cable types are listed on Page 63.

Error handling

Error messages:

E76:

E77/E78:

Note!

Transmission error

procedure:

Synchronizing

process values:

Note:

Note: