Error handling and error messages, 4 error handling and error messages – Parker Products COMPAX-M /-S (L) User Manual

Page 223

Error handling and error messages

223

Unit

hardware

Connector

assignment / cable

Technical data

Configuration

Positioning and

control functions

Optimization

functions

Interfaces

Accessories /

options

Status

Parameter

Error List:

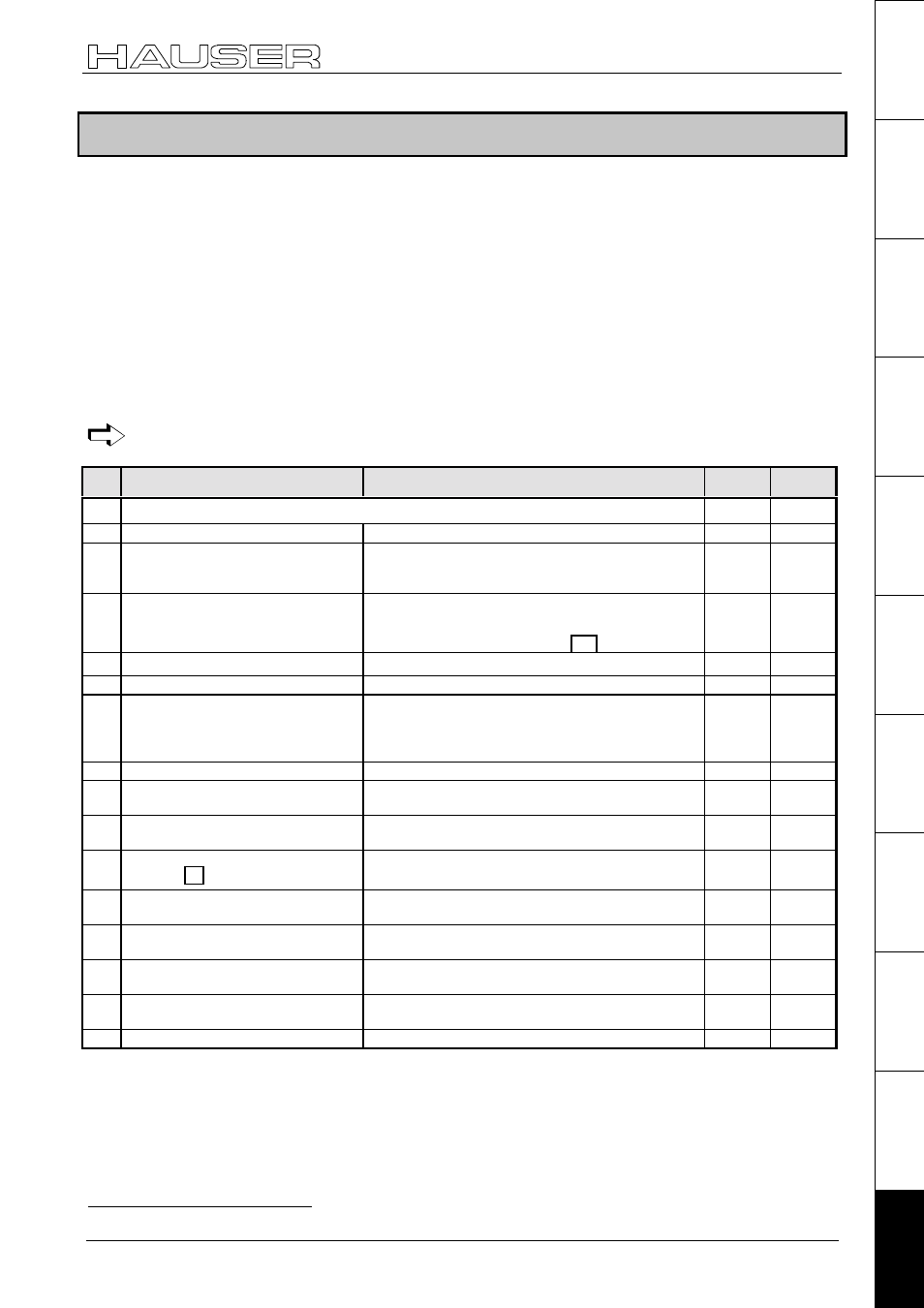

10.4 Error handling and error messages

♦

All errors are indicated by messages on the front plate error LED.

♦

An error number EXX appears in the display. You can modify parameters when an error message is present.

♦

When you have rectified the cause of the error, acknowledge the error using Enter, Quit or by switching the

unit on again (Power on).

♦

When the LED (error) turns off, COMPAX is ready for operation.

♦

Switch off COMPAX if you are experiencing hardware errors (e.g. short circuit to outputs).

♦

The errors I1...I57 are also reported with the binary output O1="0"; the drive does not accept any

positioning commands and the ready contact is opened.

♦

If COMPAX executes a travel motion, the drive is then decelerated using the programmed ramp time (for E50, E51 and E55

using ramp time P10) and, if specified in the error table, the unit is switched off after this time.

♦

The errors

≥

E58 are also indicated with the binary output O2="0" (if O2 is configured in this manner, see

parameter P227).

If the specified measures cannot rectify the problem, there may be an electrical defect. Please send

the unit and an error description to HAUSER.

No.

Cause

Action

Acknow-

ledge with

Drive

volt.-free

E00 Interruption of a positioning command using STOP / BREAK; is only reported via RS232.

Not

necessary

no

E01 Not configured.

Configure.

Quit

yes

E05 Machine zero initiator not found.

Error is only generated when using

reversing initiators.

Check initiator.

Quit

no

E07 Calculation error

Check programmed arithmetic.

(more accurate cause shown in the optimizing

display P233/243=39; see Page 133)

Quit

no

E08 Synchronous STOP present

Check P219

Quit

no

E09 Drive not running.

Remove mechanical blockage (tools, foreign bodies).

Quit

no

E10 Lag error too large.

or

speed difference too great

Check mechanics for smooth operation, reduce load

or feed force or increase P13.

This error message can be turned off by setting

P13="0".

Quit

see

below

E11 Programmed position not reached.

Remove mechanical obstacles or increase P14.

Quit

no

E15 Error in 2nd position measuring

system.

Check configuration and wiring.

Quit

yes

E16 The data record number selected

does not exist.

Select data record number between 1...250.

Quit

no

E17 The data record number selected is

too large.64

Select data record number between 1...250.

Quit

no

E18 The maximum data record 250 is

already assigned.

Free data record 250.

Quit

no

E19 No space available in data record

memory.

Delete data records or entire data record memory.

Quit

no

E20 Target position beyond positive end

limit.

Correct target position.

Quit

no

E21 Target position beyond negative end

limit.

Correct target position.

Quit

no

E22 Machine zero is not approached.

Find machine zero. This must be found after power on.

Quit

no

64

with COMPAX 70: Curve number not present.