9 grounding – Siemens Automation System S7-400 User Manual

Page 73

Wiring the S7-400

4-13

Automation System S7-400 Hardware and Installation

A5E00850741-01

4.9

Grounding

Introduction

Grounding in accordance with regulations and conscientiously implemented is the

prerequisite for proper functioning of a programmable controller.

Each individual component of the S7-400 and of the controlled system must be

properly grounded.

Ground Connections

Low-resistance ground connections reduce the risk of electric shock in the event of

a short-circuit or faults in the system. Moreover, proper grounding (low-impedance

connections: large surface area, wide-area bonding) together with the effective

shielding of lines and devices reduces the effect of interference on the system and

the interference signal emissions.

Note

Always ensure that operating currents do not flow via ground.

Protective Ground

All equipment of Safety Class I and all large metal parts must be connected to the

protective ground. This is essential to ensure that the user of the installation is

reliably protected from electric shock.

Furthermore, this serves to discharge interference transferred via external power

supply cables, signal cables, or cables to I/O devices.

Shown in Table 4-2 are the grounding methods required for the individual

components.

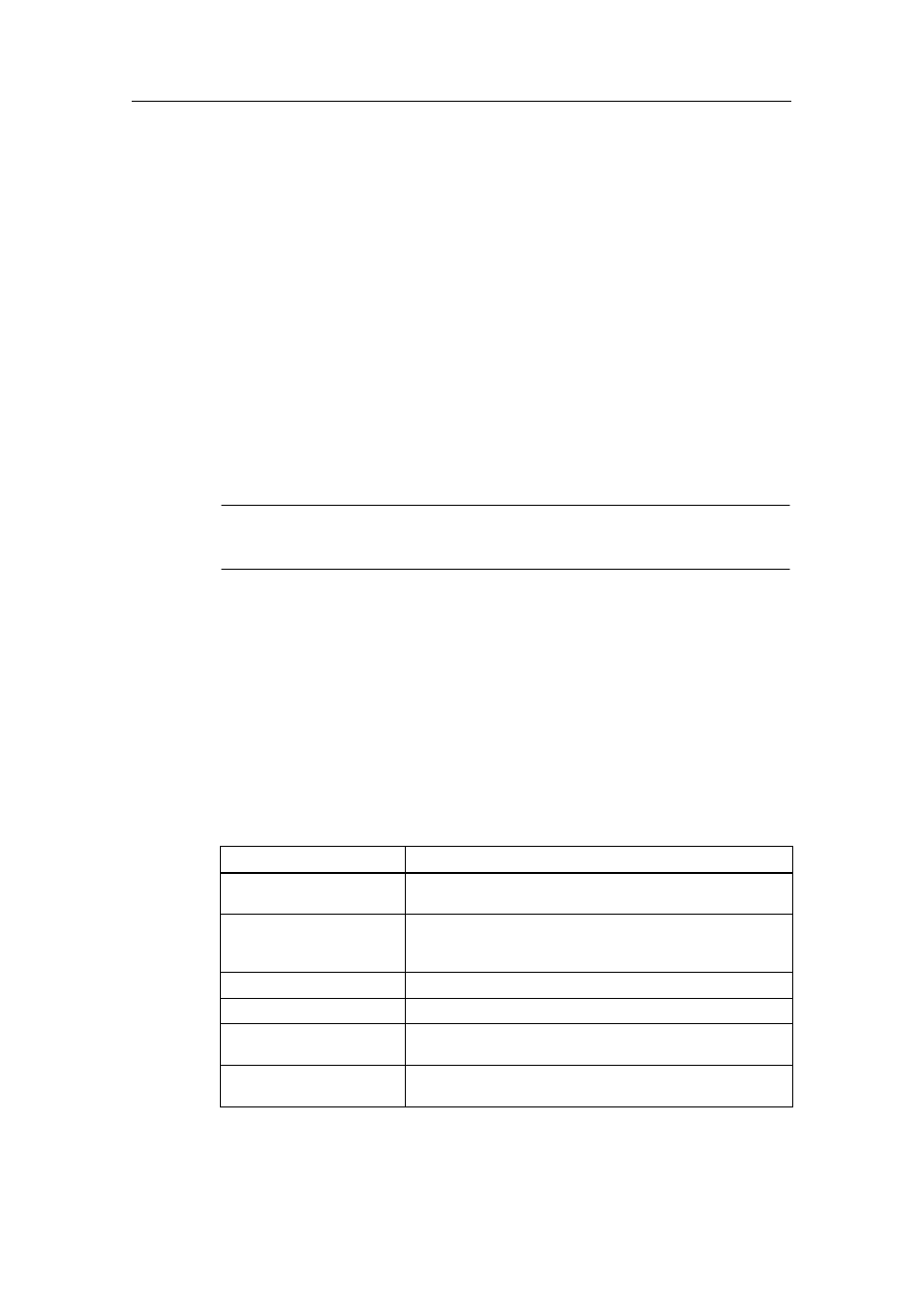

Table 4-2

Methods of Protective Grounding

Device

Grounding Method

Cabinet/frame

Connection to central ground point, e.g. ground bus, via

cable with protective conductor quality

Racks

Connection to central ground point via cable with

10 mm

2

min. cross-section, when racks are not installed in a

cabinet and not interconnected via large metal parts

Module

None; automatically grounded via backplane bus when fitted

I/O device

Grounded via power plug

Shields of connecting

cables

Connection to rack or central ground point (avoid ground

loops)

Sensors and actuators

Grounding according to specifications applying to the

system