2 choosing the power supply module – Siemens Automation System S7-400 User Manual

Page 63

Wiring the S7-400

4-3

Automation System S7-400 Hardware and Installation

A5E00850741-01

4.2

Choosing the Power Supply Module

Estimating the Power Requirement

You should make an estimate of the power requirement for each rack of your

S7-400 system in order to select the appropriate power supply module for the rack.

Current consumption and power dissipation of the individual modules can be found

in the relevant data sheets.

Calculation Example

The following modules are to be fitted in a CR with 18 slots:

• 1 CPU 414-1

• 3 analog input modules SM 431;AI 16 x 16 bits

• 5 digital input modules SM 421;DI 32 x 24 VDC

• 6 digital input modules SM 422;DO 32 x 24 VDC/0.5A

• 1 send IM, IM 460-0

You can calculate Current Consumption I in this rack as follows, with the data from

the individual data sheets:

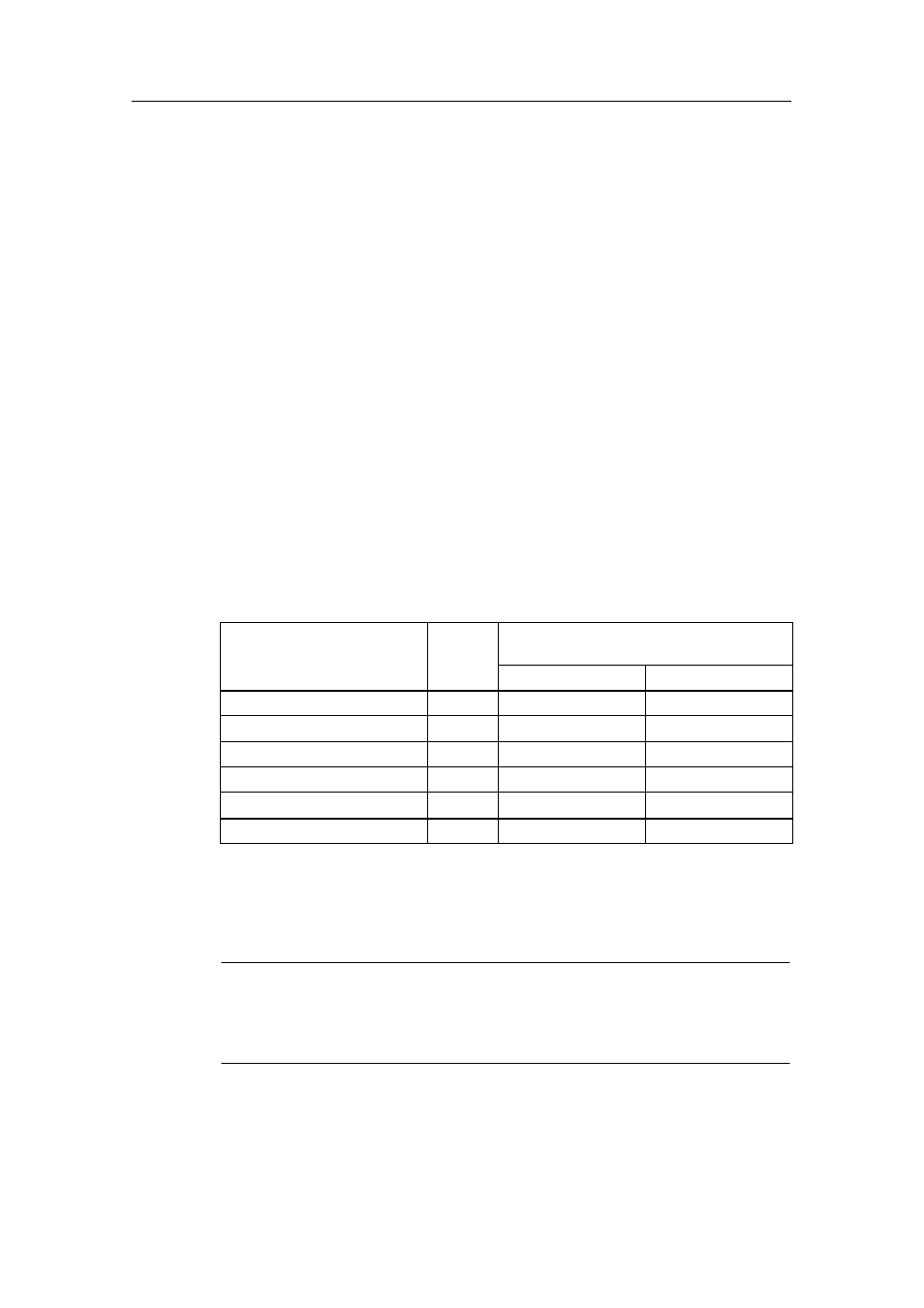

Module

Quantity

+5 VDC (Max. Current Consumption

Values)

I / Module

I Total

CPU 417-4

1

2600 mA

2600 mA

SM 431; AI 16 x 16 bits

3

700 mA

2100 mA

SM 421;DI 32 x 24 VDC

5

30 mA

150 mA

SM 422;DO 32 x 24 VDC/0.5A

6

200 mA

1200 mA

IM 460-0

1

140 mA

140 mA

Total

6190 mA

From the data in the table, you can see that you must install a power supply

module PS 407 10A (for connection to 120/230 VAC) or PS 405 10A (for

connection to 24 VDC) in the rack, to cover the current consumption calculated

here.

Note

If you wish to connect an ER to the CR via a send IM with current transfer, you

must also take the current consumption of this ER into account when choosing the

power supply module.